Nickel-chromium-aluminum-iron alloy with high resistance long-term stability

A stable, nickel-chromium-aluminum technology, which is applied in the field of nickel-chromium-aluminum-iron alloys, can solve the problems of poor long-term resistance stability, affecting the measurement accuracy of resistors, and large resistance value change rates.

Active Publication Date: 2020-07-03

CHONGQING CHUANYI AUTOMATION

View PDF4 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] However, nickel-chromium-improved alloys represented by nickel-chromium-aluminum-iron have the disadvantage that the long-term stability of resistance is not as good as that

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Login to View More

Abstract

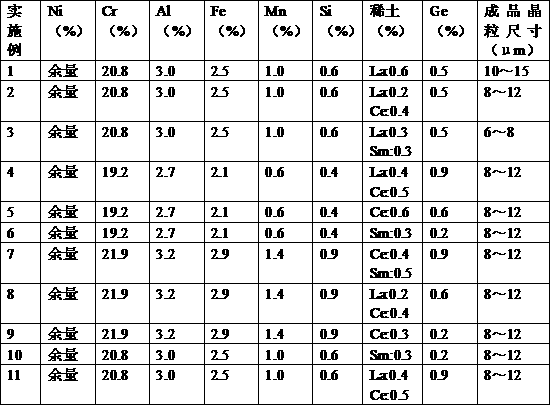

The invention relates to a nickel-chromium-aluminum-iron alloy with high resistance long-term stability. The alloy is characterized by comprising the following components of, by mass, 18%-25% of Cr, 2.0%-5.0% of Al, 1%-5% of Fe, 0.2%-2.0% of Mn, 0.2%-1.5% of Si, 0.2%-2% of Ge, 0.2%-1.5% of rare earth elements and the balance Ni, wherein the grain size of the alloy is less than or equal to 15 microns, the grain size is uniform, and the size pole difference is less than or equal to 5 microns. According to the nickel-chromium-aluminum-iron alloy with the high resistance long-term stability, the resistance long-term stability of the alloy is high, it is verified through the experiment of the applicant that the resistance long-term stability delta R/R of the alloy is less than or equal to 0.2%,the accuracy of the resistance measurement is higher, and the high-precision requirement of a measurement circuit on the measurement in the high-end application field is met.

Description

technical field [0001] The invention belongs to the field of metal materials, in particular to a nickel-chromium-aluminium-iron alloy with high resistance long-term stability. Background technique [0002] In the field of precision resistance alloys, manganese-copper alloys have been dominant for nearly a hundred years, but due to its shortcomings such as low resistivity, large temperature coefficient of secondary resistance, narrow temperature range, poor oxidation resistance and wear resistance, etc. With its wide application. For a long time, all countries in the world have been constantly committed to the development of new alloys. The nickel-chromium-improved resistance alloy is a high-resistance precision resistance alloy developed on the basis of nickel-chromium electrothermal alloys. The typical domestic brand is nickel-chromium-aluminium-iron (6J22 ), nickel-chromium-aluminum-copper (6J23), which has high resistivity, and the resistance temperature system can reach...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22C19/05

CPCC22C19/058

Inventor 杨贤军喻文新徐永红吴达

Owner CHONGQING CHUANYI AUTOMATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com