Precise conveying mechanism of high-precision weight reduction type weighing scale

A conveying mechanism and measuring scale technology, which is applied in the field of material transmission, can solve problems such as instability, inaccurate feeding, and affecting production quality, so as to achieve high-speed and high-torque output, improve measurement accuracy, and improve measurement accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

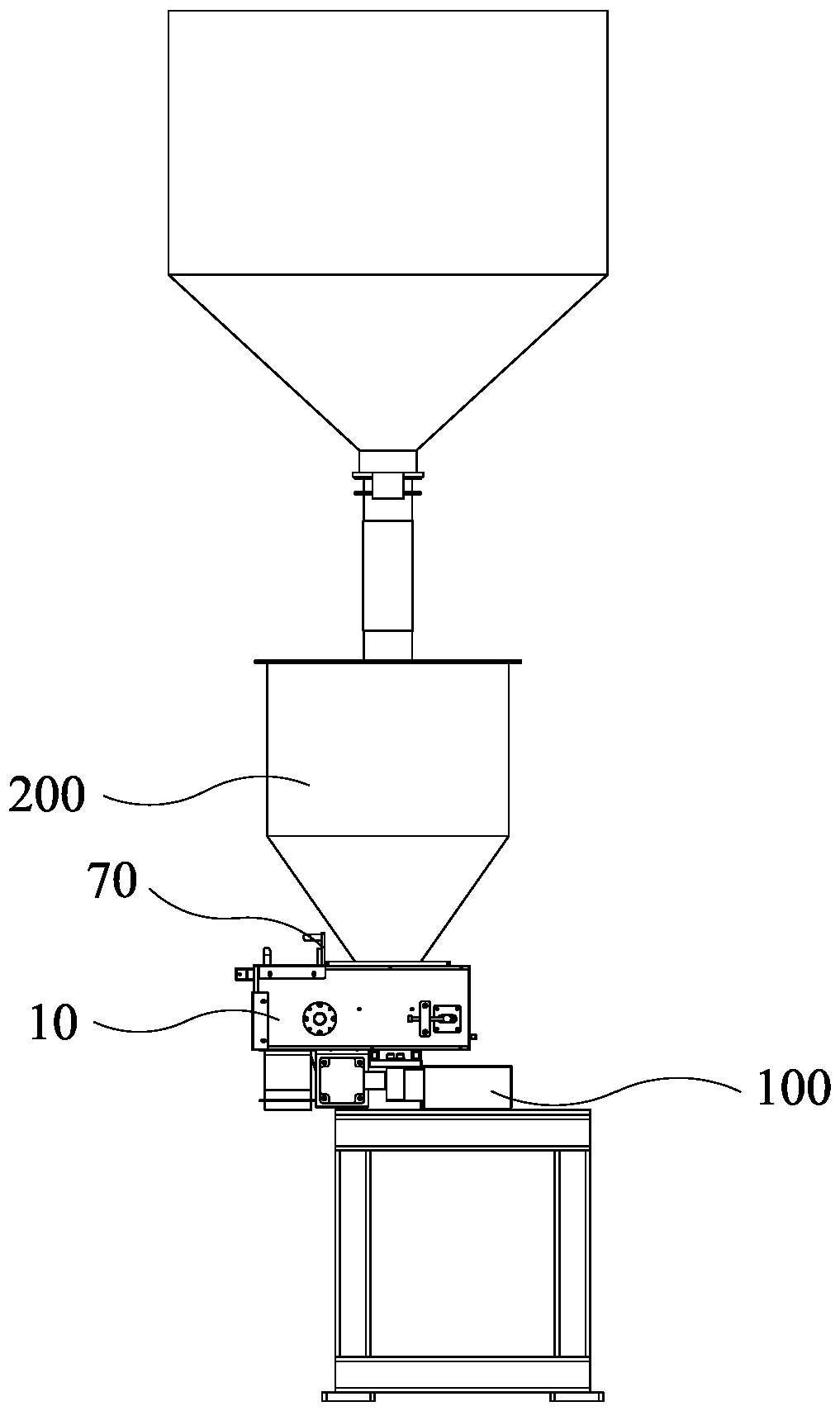

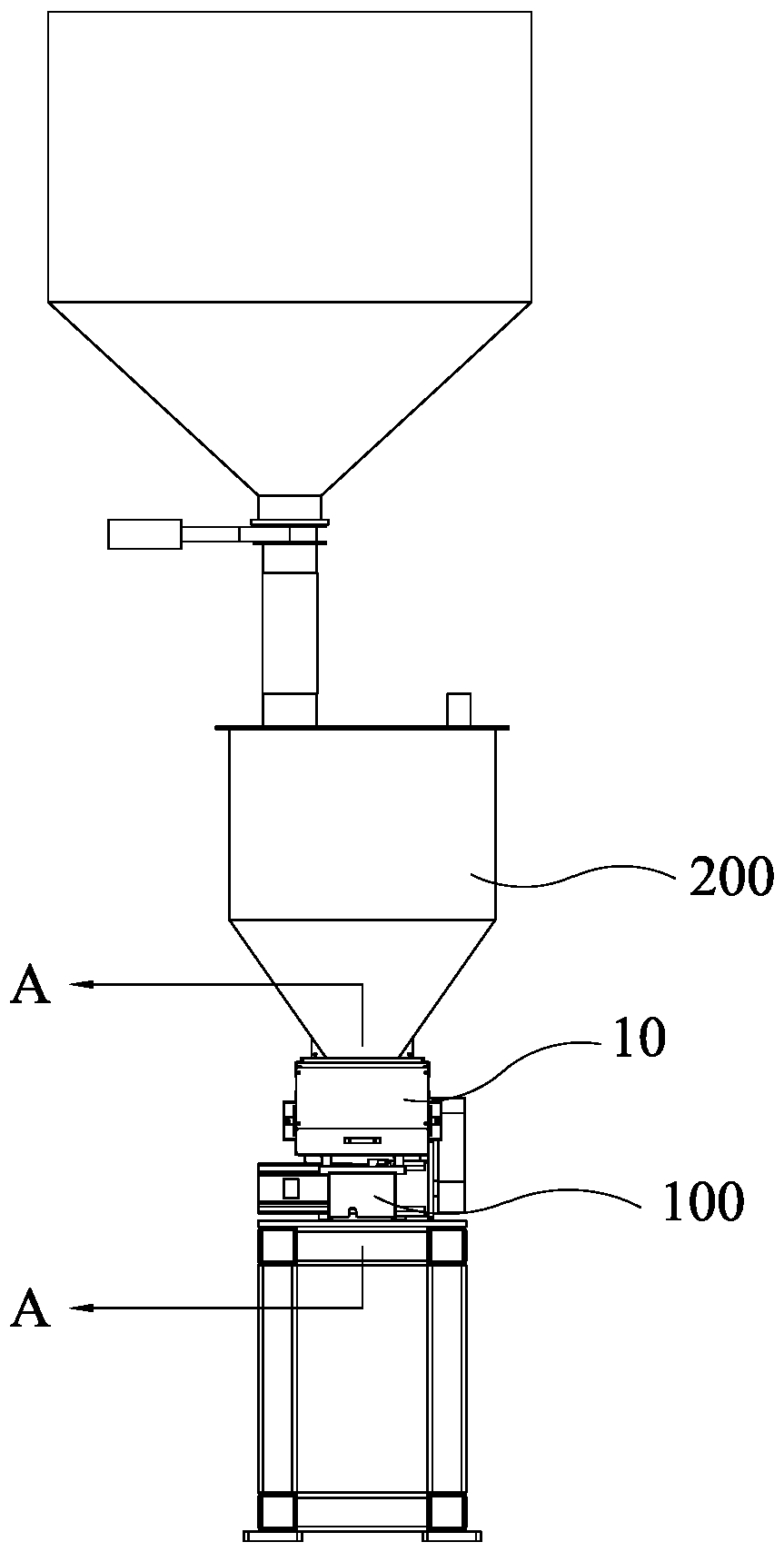

[0024] The present invention is a precise conveying mechanism for a high-precision weight-reducing weighing scale, which includes a housing 10 with a feeding bin 11 , oppositely arranged driving wheel assemblies 20 and driven wheel assemblies 30 , conveyor belts 40 and driving assemblies 50 .

[0025] The feeding bin 11 is provided with a material inlet 12 and a material outlet 13 .

[0026] Both the driving wheel assembly 20 and the driven wheel assembly 30 are installed in the feeding bin 11 .

[0027] The inner side of the above-mentioned conveyor belt 40 is provided with a toothed synchronous belt 41, and the two ends of the synchronous belt 41 are respectively engaged on the synchronous wheel 21 of the driving wheel assembly 20 and the driven wheel assembly 30, and the center of the conveyor belt 40 is loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com