Method and equipment for automatically controlling the output of waste plastics

A technology of waste plastics and output volume, which is applied in the direction of conveyor objects, transportation and packaging, etc., and can solve the problems of low weighing efficiency and inaccurate weighing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

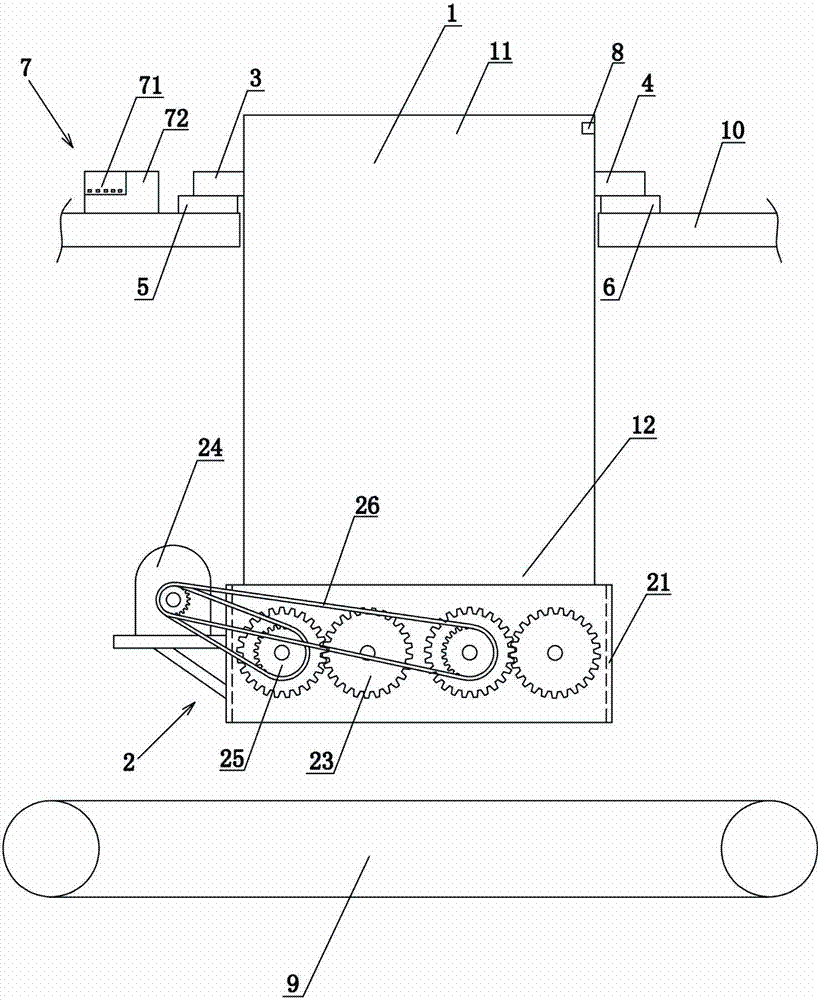

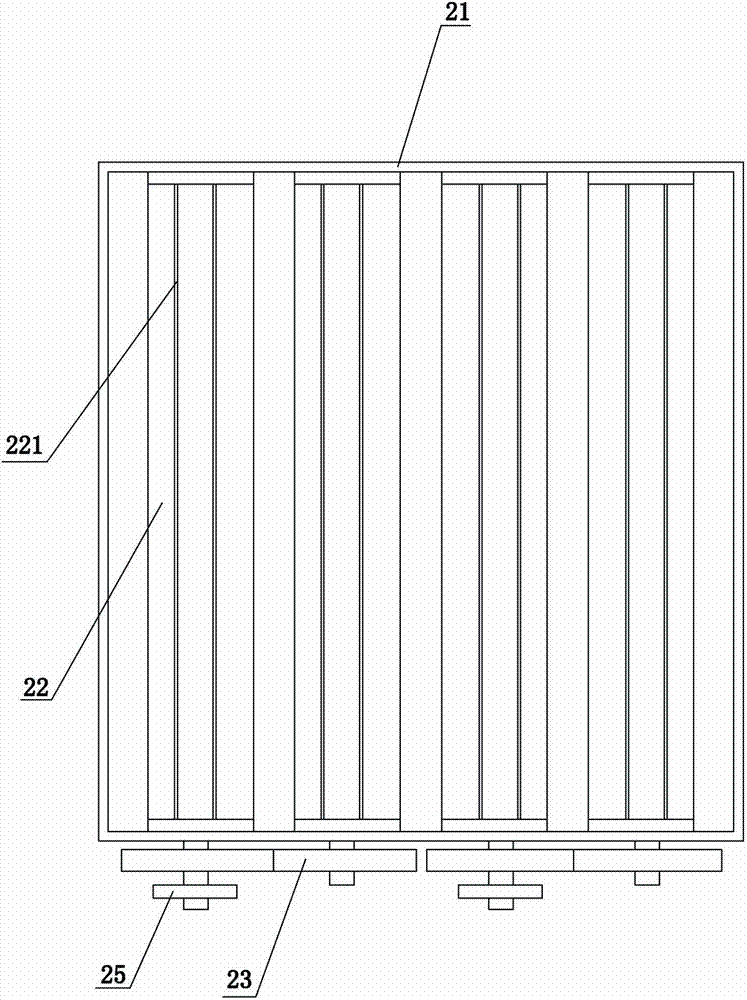

[0021] The method for automatically controlling the discharge amount of waste plastics comprises the following steps:

[0022] 1) The feed volume of the silo and the discharge speed of waste plastics in the silo are preset through the controller.

[0023] 2) Feed into the silo, stop feeding into it when the preset feed amount is reached, and weigh the gross weight of the silo.

[0024] 3) The controller prompts the silo to carry out the unloading operation, and calculates the change in the gross weight of the silo within a certain period of time, and calculates the actual average of the discharge speed of the waste plastics in the silo within this time according to the change Value, the actual average value is compared with the set value of the preset discharge speed and a feedback signal is obtained.

[0025] 4) According to the obtained feedback signal, send it to the controller to prompt it to control the discharge speed of waste plastics in the silo. When the actual avera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com