Double-body energy saving material mixer

A material mixing and energy-saving technology, which is applied in the field of two-body energy-saving material mixer, can solve the problems of long time for uniform mixing, poor material mixing quality, and heavy weight of the mixer, so as to improve uniformity and error-free mixing quality , the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

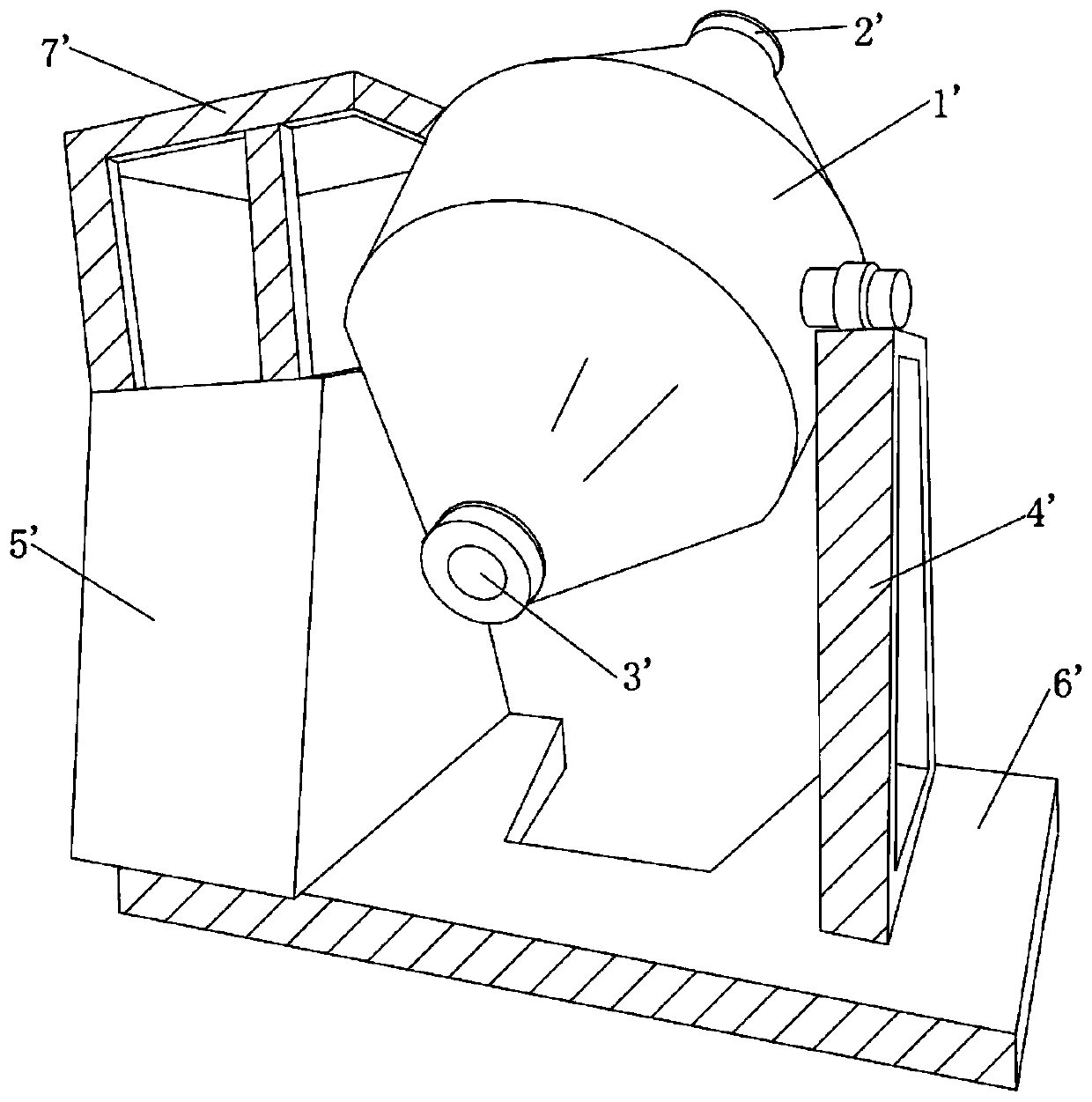

[0049] see figure 2 with Figure 5 As shown, this embodiment provides a two-body energy-saving material mixer, including: a support drive assembly 200, which is composed of a support frame and a drive motor 203 arranged on the support frame; at least one set of cylinder assemblies 100 , which includes a cross-connected first cylinder 101 and a second cylinder 102, the outer wall of the first cylinder 101 is fixedly provided with a turning gear 104, and the first cylinder 101 and the second cylinder 102 The connecting shafts 105 arranged on the outer side walls are respectively mounted on the support frame; wherein, the driving motor 203 is meshed with the turning gear 104 to drive the first cylinder 101 and the second cylinder. The barrel 102 is rotated and flipped synchronously on the support frame. By arranging the first cylinder 101 and the second cylinder 102 in a cross-displacement arrangement, and turning them over by driving a driving motor 203, the materials in the ...

Embodiment 2

[0056] see image 3 with Image 6 As shown, different from the above-mentioned embodiment 1, this embodiment provides a cylinder assembly 100 with several stirring shafts 108, and the cylinder assembly 100 also includes: a movably arranged outside of the second cylinder 102 The transmission gear 111 on the connecting shaft 105 of the wall, the diameter of the transmission gear 111 is smaller than the diameter of the turning gear 104; A stirring gear 110 , the stirring gear 110 is axially connected with the stirring shaft 108 penetrating through the first cylinder 101 and the second cylinder 102 . The cylinder assembly 100 makes full use of the transmission properties of the second cylinder itself, and flexibly adjusts the limit adjustment of the transmission gear 111 on the second cylinder 102, so as to control whether the transmission gear 111 is driven or stationary relative to the second cylinder 102, so that When the cylinder is turned over, multiple stirring shafts are ...

Embodiment 3

[0066] see Figure 9 As shown, different from the above-mentioned embodiment 1, this embodiment provides a two-body energy-saving material mixer with a double-cylinder assembly 100. On the two-body energy-saving material mixer, the cylinder The components 100 are divided into two groups and arranged symmetrically; wherein, the flip gears 104 on the two groups of cylinder components 100 are respectively connected to the same drive motor 203 through a cross commutator 204, and the drive motor 203 adopts Turbo worm motor. And according to the actual production demand, such as Figure 9 As shown, the driving motor 203 can be installed at the lower part of the cylinder assembly 100 to facilitate installation and maintenance; the driving motor 203 can also be installed at the upper position of the cylinder assembly 100 to free up the space below the cylinder assembly 100 , The design is reasonable, which improves the convenience of the staff's operation.

[0067] In this embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com