A chip motherboard processing system

A processing system and motherboard technology, which is applied in the direction of assembling printed circuits with electrical components, can solve the problems of reducing welding efficiency, reducing comfort, and unable to adjust the position of the motherboard, so as to achieve the effect of improving comfort and work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

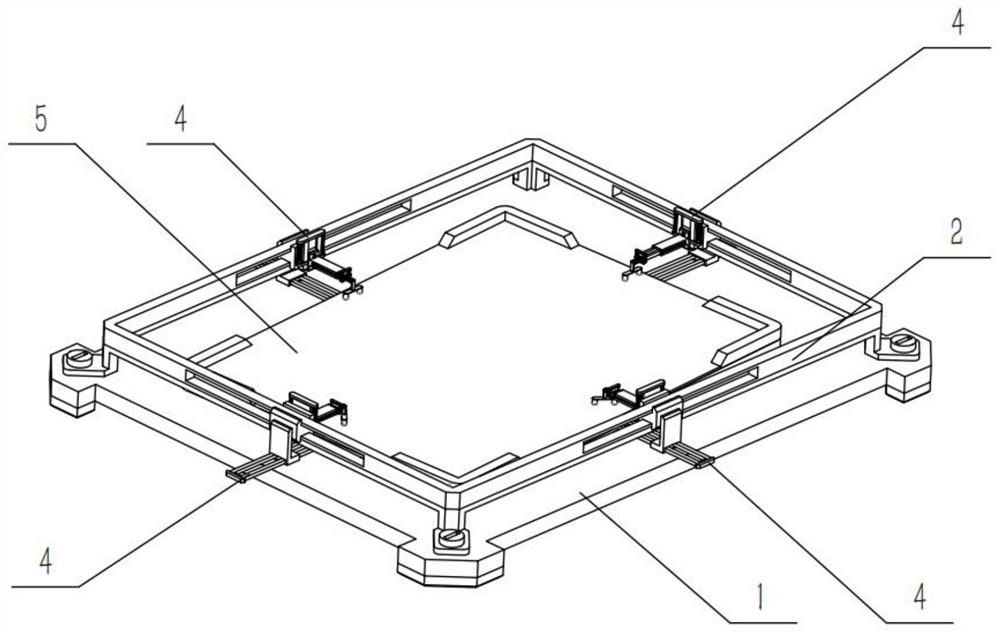

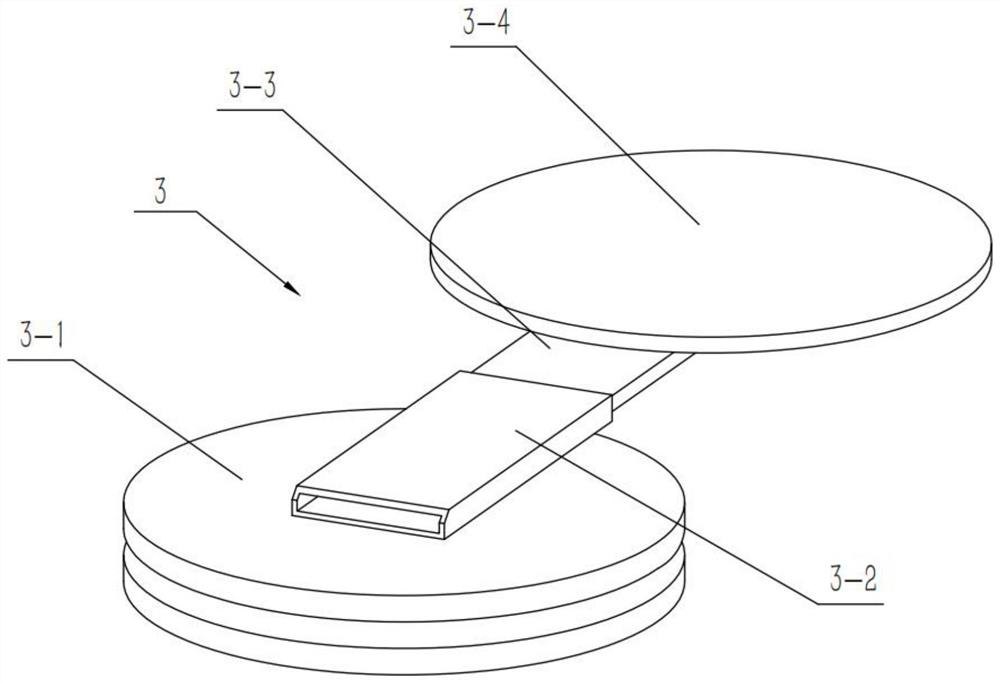

[0035] Combine below Figure 1-11Describe this embodiment, a chip motherboard processing system, including a base 1, an installation frame 2 and a clamping mechanism 4, the installation frame 2 is fixedly connected to the base 1, the chip motherboard processing system also includes a rotating shaft structure 3 and Workbench 5, the rotating shaft structure 3 is rotatably connected to the middle part of the base 1, the workbench 5 is fixedly connected to the upper end of the rotating shaft structure 3, the clamping mechanism 4 is composed of a connecting part 6, an elastic mechanism I7, The sliding part 8, the elastic mechanism II9 and the pressing part 10, the elastic mechanism I7 is fixedly connected to the upper end of the connecting part 6, the sliding part 8 is slidably connected to the elastic mechanism I7, and the elastic mechanism II9 slides Connected in the sliding part 8, the pressing part 10 is slidably connected to the elastic mechanism II9, the clamping mechanism 4 ...

specific Embodiment approach 2

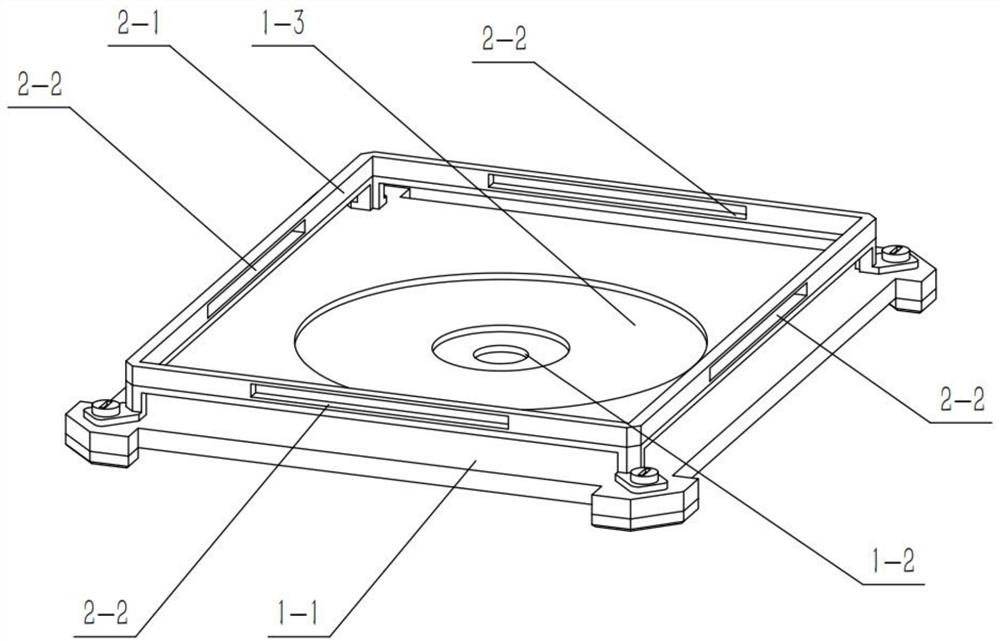

[0038] Combine below Figure 1-11 Describe this embodiment, this embodiment will further explain Embodiment 1, the base 1 includes a bottom plate 1-1, a rotating hole 1-2 and a circular groove 1-3, and the circular groove 1-3 is arranged on the bottom plate 1 -1, the rotating hole 1-2 is set in the middle of the circular groove 1-3, the mounting frame 2 is fixedly connected to the bottom plate 1-1, and the rotating shaft structure 3 is rotatably connected to the In the transfer hole 1-2.

specific Embodiment approach 3

[0040] Combine below Figure 1-11 Describe this embodiment, this embodiment will further explain the second embodiment, the installation frame 2 includes a frame 2-1 and a slideway 2-2, the frame 2-1 is fixedly connected to the bottom plate 1-1, There are four slideways 2-2, and the four slideways 2-2 are respectively arranged on the four sides of the frame 2-1, and the four elastic mechanisms I7 are slidably connected to the four slideways 2-2 respectively. Inside.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com