Concrete prefabricated pipe piles that only bear the pull-out effect

A technology of concrete prefabricated piles and prefabricated pipe piles, which is applied to sheet pile walls, buildings, infrastructure engineering, etc. The effect of using the range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

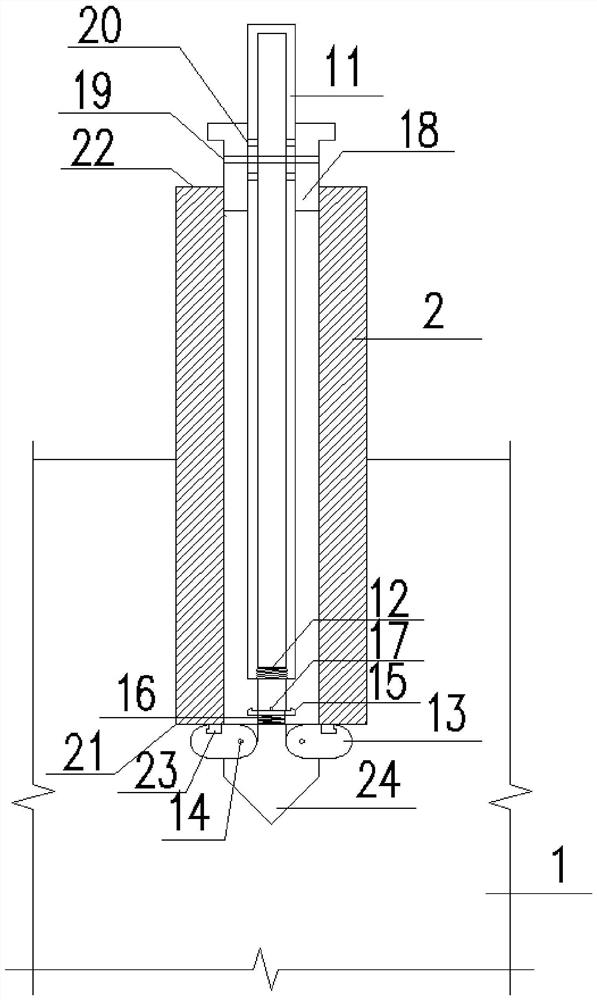

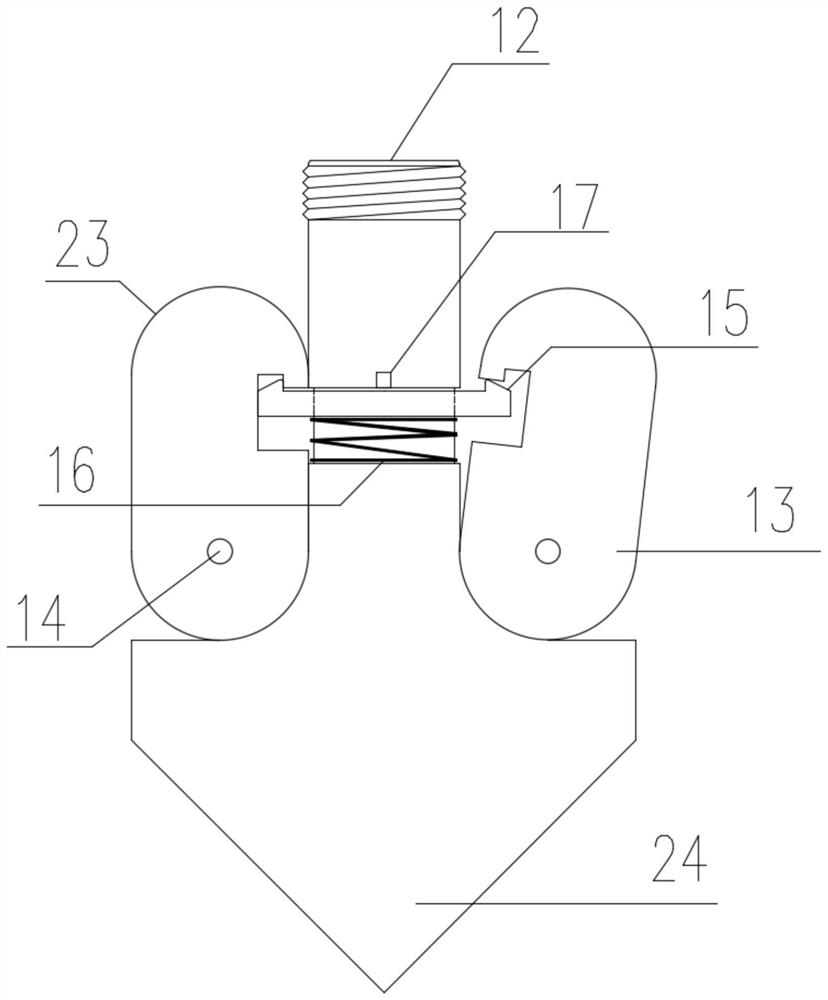

[0019] Such as figure 1 , figure 2 As shown, the concrete prefabricated pipe pile that only bears the pull-out effect includes: the concrete prefabricated pile body 2, the detachable hollow guide rod 11, the metal pile tip 24, the concrete prefabricated pile body 2 is the prefabricated concrete hollow pipe pile, and the concrete prefabricated pile body 2. It has a pile top 22 and a pile bottom 21. The concrete prefabricated pile body 2 is driven into the foundation soil 1; the cavity of the concrete prefabricated pile body 2 is provided with a detachable hollow guide rod 11, and the top of the detachable hollow guide rod 11 is sleeved with a pile The top stabilizing ring 18, the top of the detachable hollow guide rod 11 is provided with a number of limit holes 20, the pile top stabilizing ring 18 is fixed on the detachable guide rod 11 through the limit bolt 19; the pile top stabilizing ring 18 is inserted into the concrete prefabricated pile body 2 Inside the top; the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com