A multi-station filling machine for cosmetic finished liquid

A multi-station, cosmetics technology, applied in liquid bottling, bottling machines, liquid treatment, etc., can solve the problems of reducing processing efficiency, increasing labor costs, increasing power costs, etc., and achieves the goal of improving service life and cleaning the bottle mouth Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

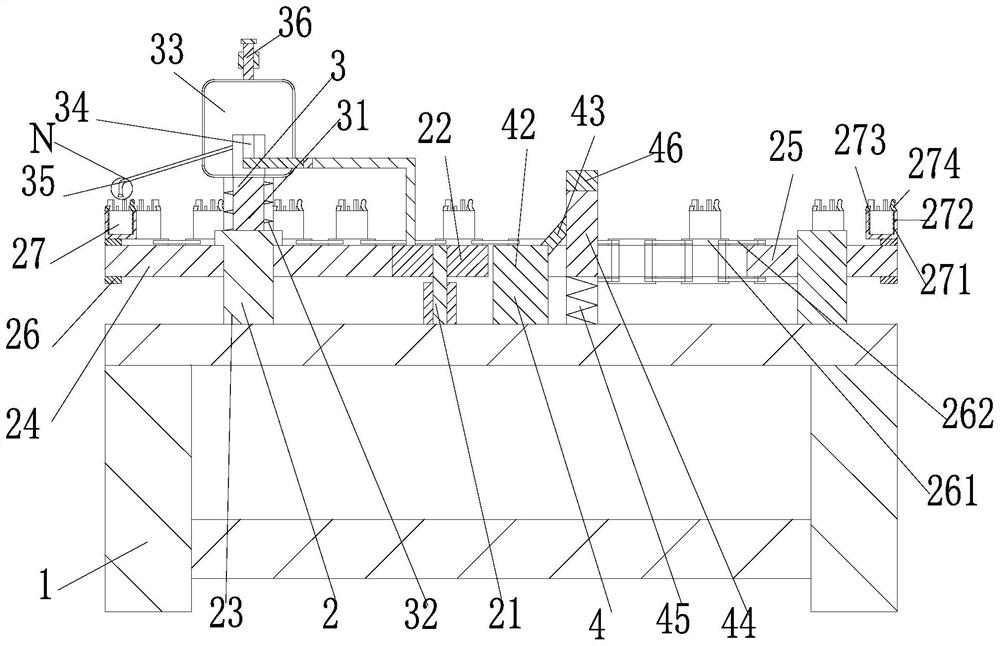

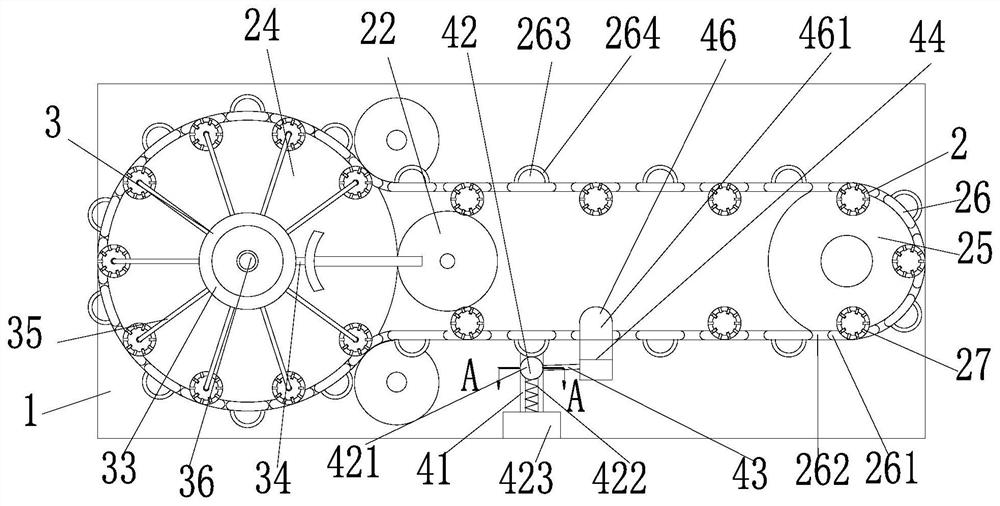

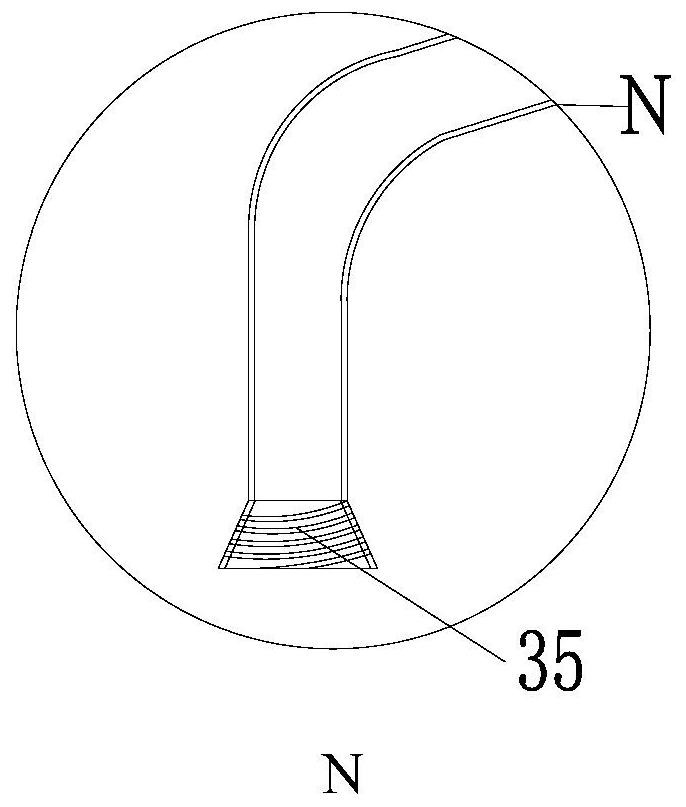

[0033] In order to make the technical means, the creation characteristics of the present invention, the purpose and efficiency are easy to understand, the following combination Figures 1 to 7 Further, the invention is further illustrated.

[0034] A cosmetic finished liquid multi-station filling machine, including a table 1, a transmission device 2, a perfusion device 3, and a cleaning device 4, the upper end of the table 1 mounting a transmission device 2, the upper end upper end of the table 1 mounting a perfusion device 3, the table 1 on the right end is installed with cleaning device 4; where:

[0035] The transmission device 2 includes a motor 21, a gear 12, a fixing post 23, a gear 24, a gear three 25, a rack chain 26, and a fixed frame 27. The upper end of the table 1 is fixedly mounted by a motor 21, and a motor 21 is fixed. The upper end output shaft of the motor 21 is mounted with a gear 122 through a coupling, and the gear 22 is engaged with gear 24, and the upper end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com