A Lifting Automatic Drilling Machine

A lifting and drilling machine technology, applied in boring/drilling, drilling/drilling equipment, driving devices, etc., can solve the problems of polluted indoor hygiene, low safety factor, and debris and dust hurting people.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

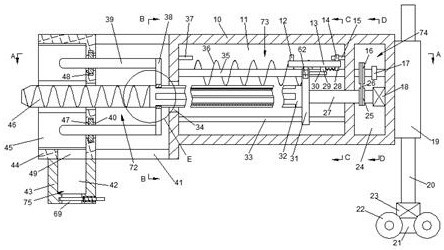

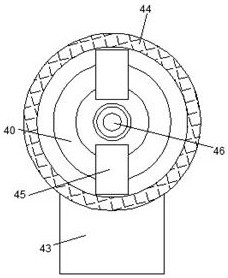

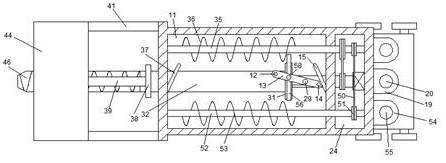

[0021] Combine below Figure 1-10 The present invention will be described in detail. For the convenience of description, the following directions are specified as follows: figure 1 The vertical, horizontal, front and rear directions of the projection relationship are the same.

[0022] Reference Figure 1-10 According to an embodiment of the present invention, a lifting automatic drilling machine includes a body 10, the right side wall of the body 10 is fixedly provided with a fixing nut 19, and the right side wall of the body 10 is centered on the fixing nut 19 The front and rear positions are symmetrically fixed with a guide block 54, the lower side of the body 10 is provided with a base 21, the upper side wall of the base 21 is fixedly mounted with a motor 23, and the upper side wall of the motor 23 is rotatably mounted with the fixed The screw rod 20 is screwed with the nut 19, the guide block 54 is slidably provided with a guide rod 55, and the guide rod 55 is fixed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com