Physical simulation method and system based on digital twin for production line

A physical simulation and production line technology, applied in the general control system, control/regulation system, comprehensive factory control, etc., can solve the problems that cannot be reflected at the same time, aggravate design repetition, separate information data and physical data, etc., and achieve shortening The effect of design cycle, reduction of revision times, and good design results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0085] (1) Preliminary preparation and system analysis: According to the production capacity and technical plan of the proposed project, complete the primary selection of equipment. Systematic analysis of the production line, comprehensive workshop material flow, actual site environment, operating space required for equipment, manufacturing and assembly process and many other factors, preliminarily determine the layout strategy of the production line.

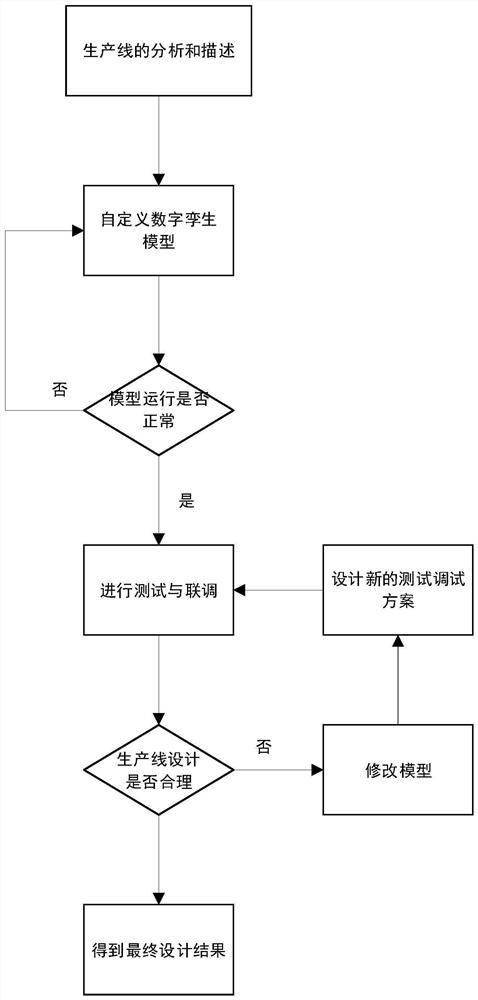

[0086] (1) Construction of multi-dimensional dynamic model: On the basis of step (1), based on the pre-constructed general digital twin model, combined with the specific production line design requirements to customize the digital twin model of the corresponding physical equipment, including:

[0087] (s1) Complete the mapping of the geometric shape of the production line equipment from physical space to virtual space;

[0088] (s2) Analyze the commonality and individuality between the behaviors of production equipment, modify ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com