A device for observing the surface interface of variable temperature solid-state batteries by in-situ electrochemical atomic force microscopy

An atomic force microscope and in-situ electrochemical technology, applied in the field of electrochemical testing, can solve problems such as single function and inability to test, and achieve the effect of simple overall structure, balanced overall temperature distribution, and uniform force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

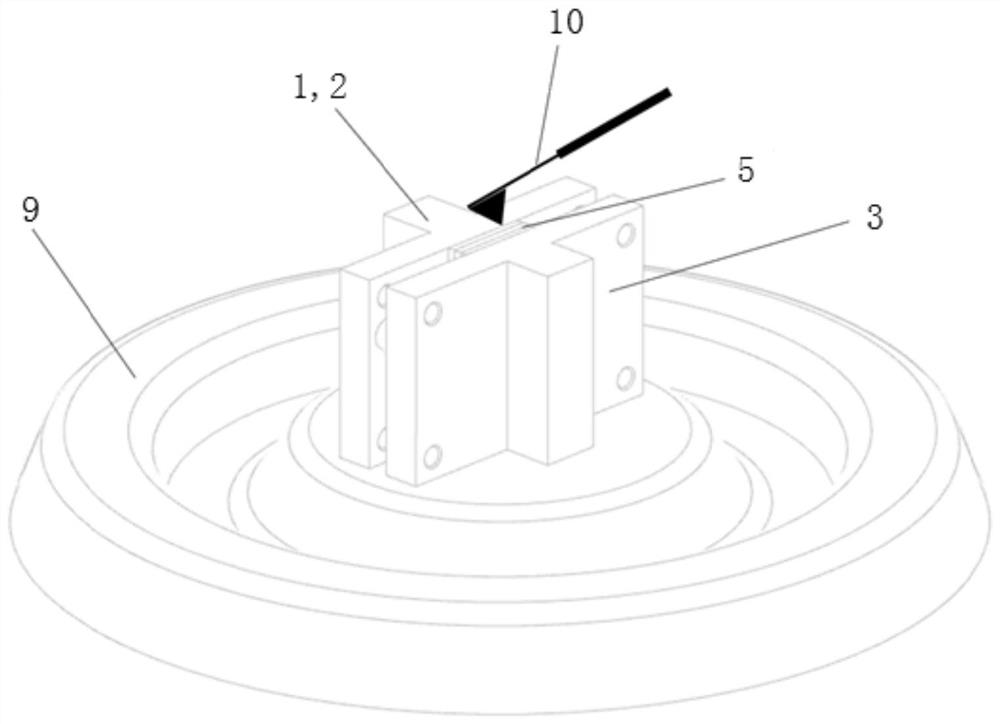

[0031] The device provided by the present invention for observing the surface interface of variable-temperature solid-state batteries with an in-situ electrochemical atomic force microscope is easy to install and has high operability, and can measure solid-state lithium ions at different temperatures through an electrochemical atomic force microscope during battery charging and discharging. The physical characteristics of the surface and interface of the battery, such as morphology, modulus, and surface potential, are detected online to analyze the failure mechanism of solid-state batteries.

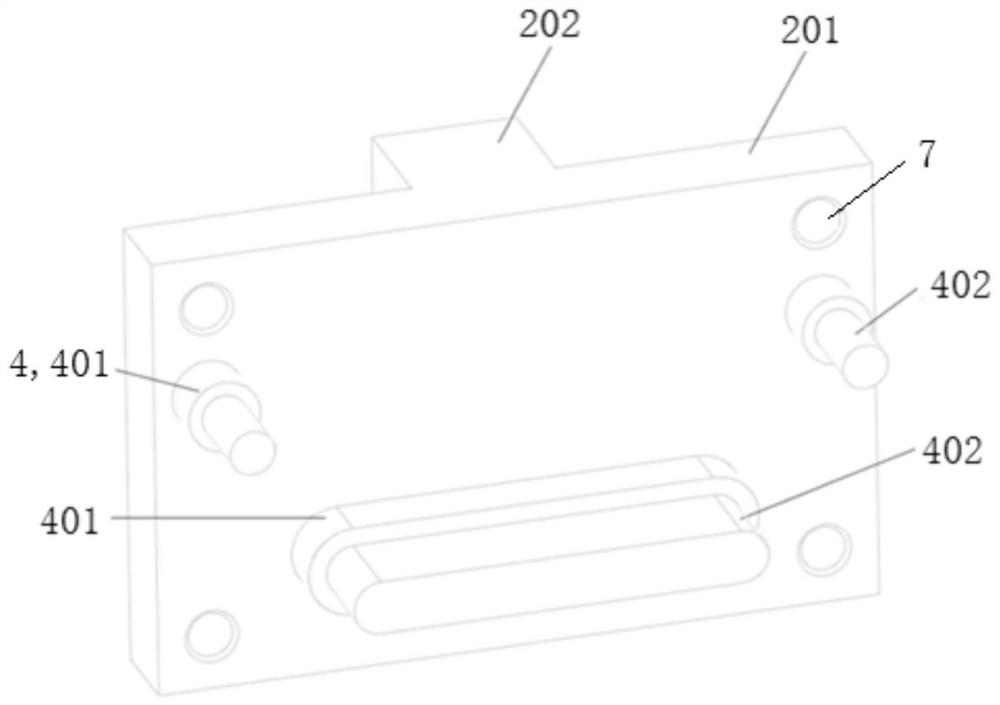

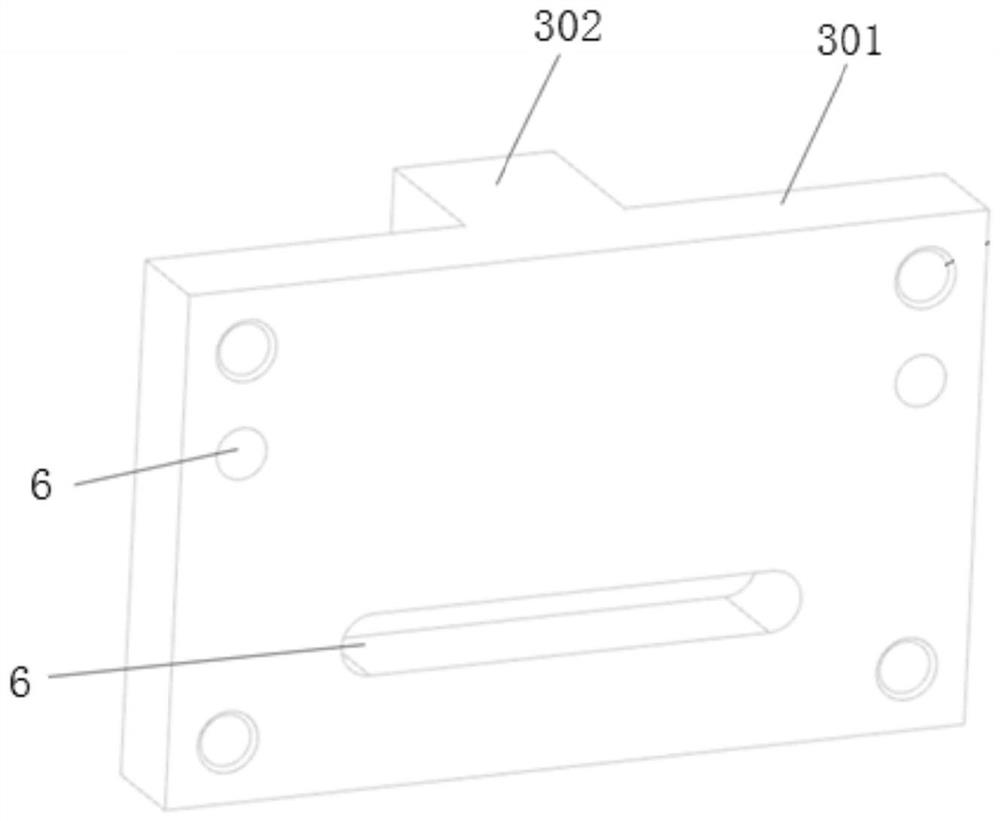

[0032] The device for observing the surface interface of a variable temperature solid-state battery by the in-situ electrochemical atomic force microscope is as follows: Figure 1-3 As shown, it includes a battery clamp 1 and a temperature control device 9 below it. The battery clamp 1 includes a conductive plate 2 and an insulating plate 3. The positive pole of the solid-state battery 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com