Energy conveying pipeline connecting and paving construction method

A technology for conveying pipelines and construction methods, which is applied in the directions of pipeline laying and maintenance, pipeline supports, pipes/pipe joints/pipe fittings, etc., can solve problems such as pipeline leakage, staggered connection ports, and misaligned pipelines, so as to improve engineering quality and avoid problems. Water leakage, the effect of increasing the working life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

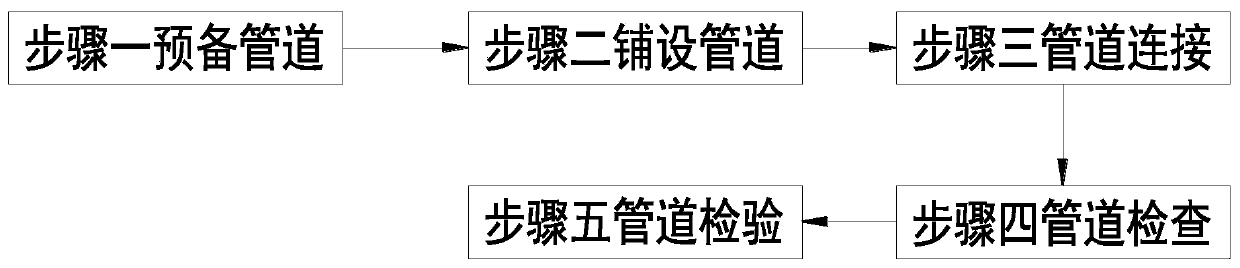

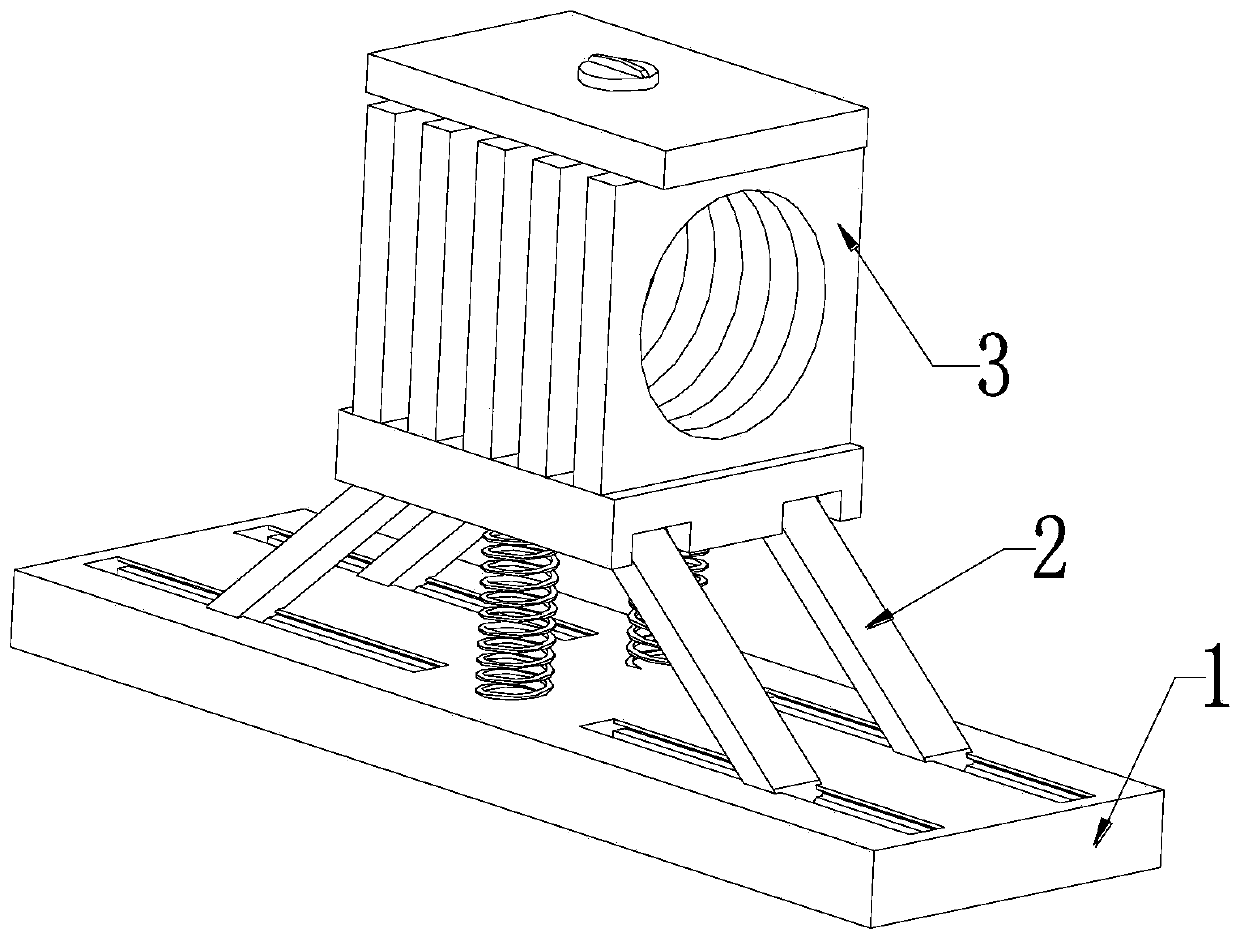

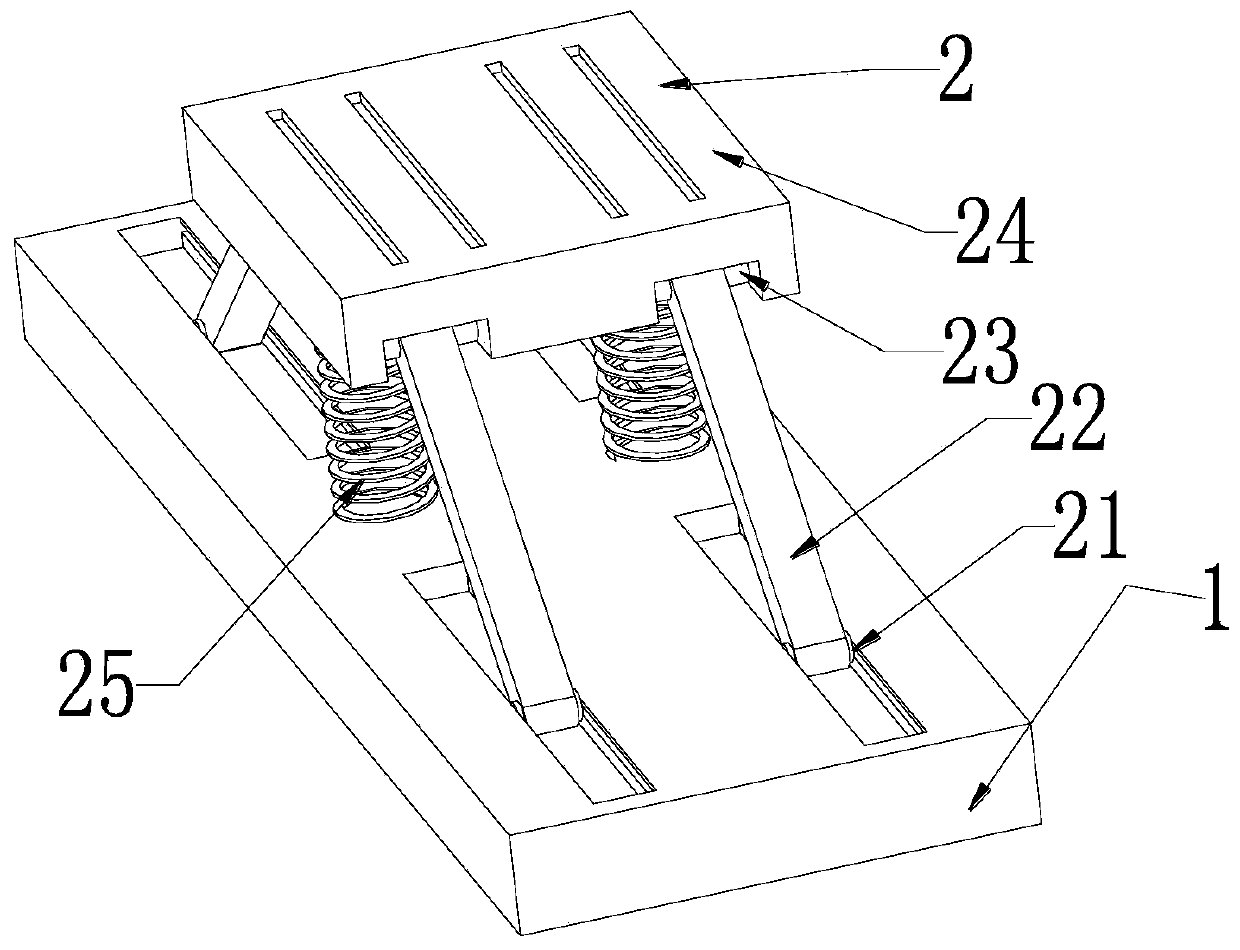

[0036] Such as Figure 1 to Figure 10 As shown, an energy transmission pipeline connection laying construction method mainly includes the following steps:

[0037] Step 1, prepare the pipeline: transport the prepared pipeline to the designated location according to the work requirements, and arrange them in the order of installation;

[0038]Step 2, laying the pipeline: the pipeline prepared in the above step 1 is raised to a specified height, and the pipeline is fixed;

[0039] Step 3, pipeline connection: the pipeline connection sealing device is set at the pipeline connection after the above-mentioned step 2 is fixed, the pipeline connection sealing device works, the pipeline connection is sealed, and the pipeline connection operation is complet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com