Construction method of anti-seepage structure in inclined shaft section of diversion tunnel

A technology for water diversion tunnels and construction methods, applied in water conservancy projects, marine engineering, hydropower generation and other directions, can solve problems affecting power generation benefits, and achieve the effect of ensuring power generation benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

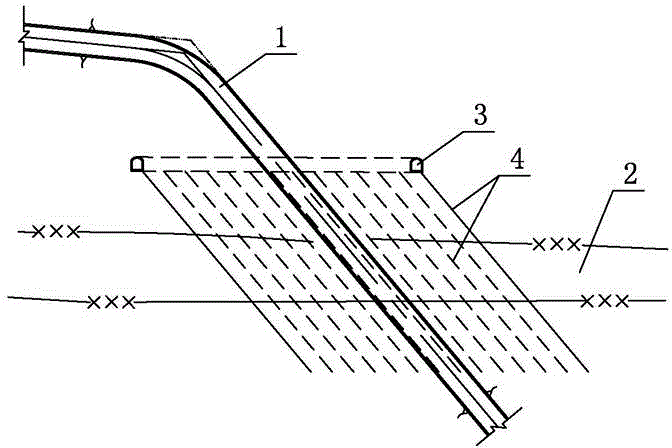

[0024] Embodiment 1: as figure 1 As shown, the construction steps of this embodiment are as follows,

[0025] a. According to the geological survey data and leakage detection analysis, determine the leakage location of the inclined shaft 1 and the water leakage area 2 of the surrounding rock.

[0026] b. In the non-leakage area of the surrounding rock above the leaking part, and on the periphery of the inclined shaft 1, excavate a circle of horizontally arranged annular grouting corridors 3 using the construction branch hole 7; after the excavation of the grouting corridor 3 is completed, first carry out Reinforced concrete lining construction, followed by backfill grouting and consolidation grouting for the lining. After the reinforced concrete lining construction is completed, the top arch will be hollowed out, and backfill grouting is required; the consolidation grouting is carried out 7 days after the backfill grouting is completed, the purpose is to strengthen the rock...

Embodiment 2

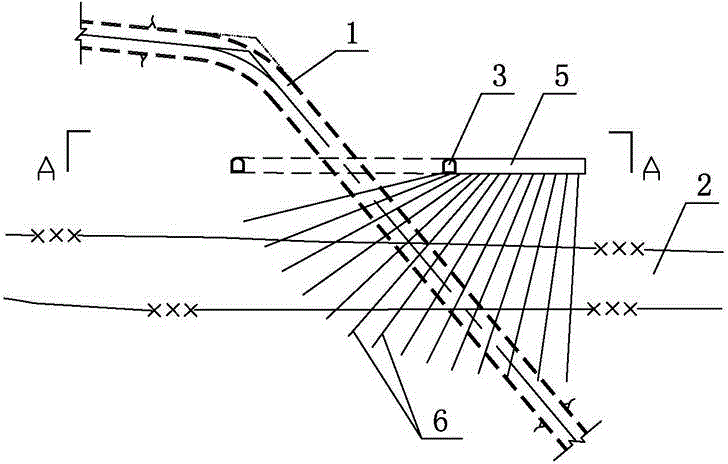

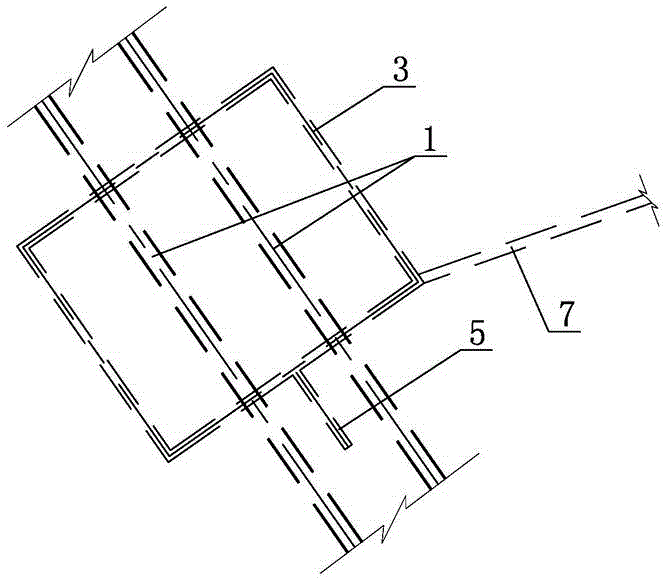

[0029] Embodiment 2: as figure 2 , image 3 As shown, this embodiment is mainly aimed at the situation of two or more than two tunnels, and the specific construction steps are as follows,

[0030] a. According to the geological survey data and leakage detection analysis, determine the leakage location of the inclined shaft 1 and the water leakage area 2 of the surrounding rock.

[0031] b. In the non-leakage area of the surrounding rock above the leakage site, excavate a circle of horizontally arranged annular grouting corridors 3 by using the construction branch hole 7 around the inclined shaft 1, and excavate a circular grouting corridor 3 between two adjacent inclined shafts 1 The grouting branch hole 5 connected with the grouting gallery 3, in this example, the grouting branch hole 5 and the grouting gallery 3 are located on the same level.

[0032] c. Carry out reinforced concrete lining construction for the grouting corridor 3 and grouting branch hole 5, and then ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com