A method for growing uranium dioxide crystals using alumina flux

A technology of uranium dioxide and flux, which is used in chemical instruments and methods, melts from molten solvents, and single crystal growth, etc., to reduce radiation swelling and fission gas release, avoid oxidation, and improve safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

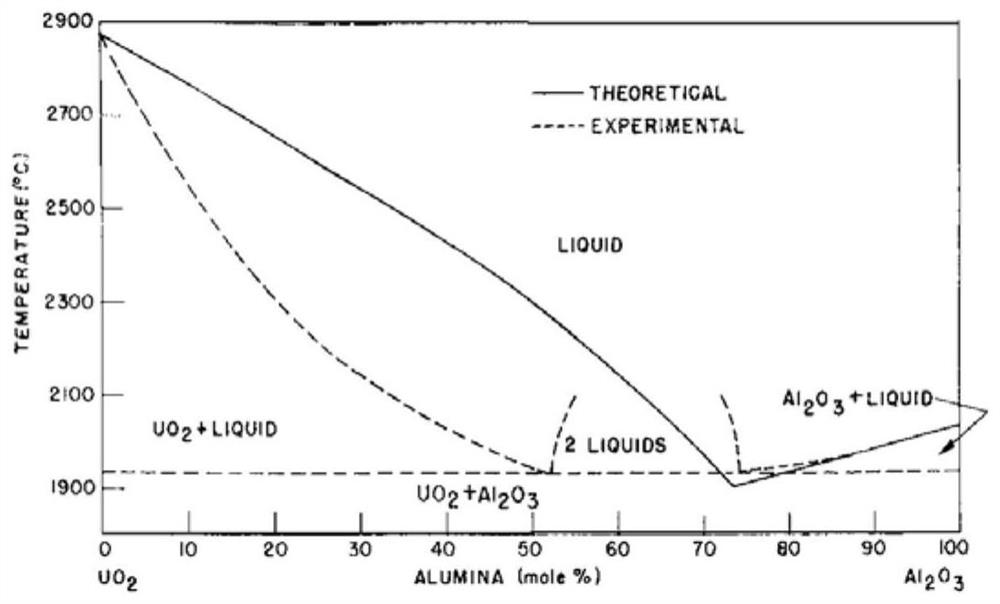

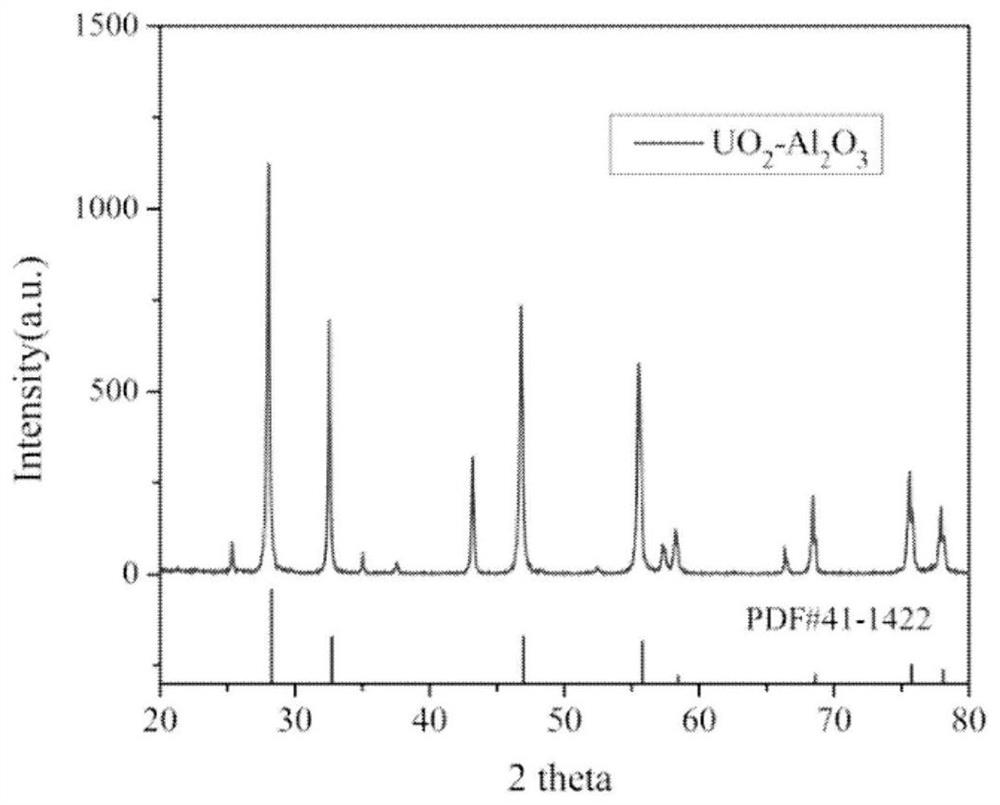

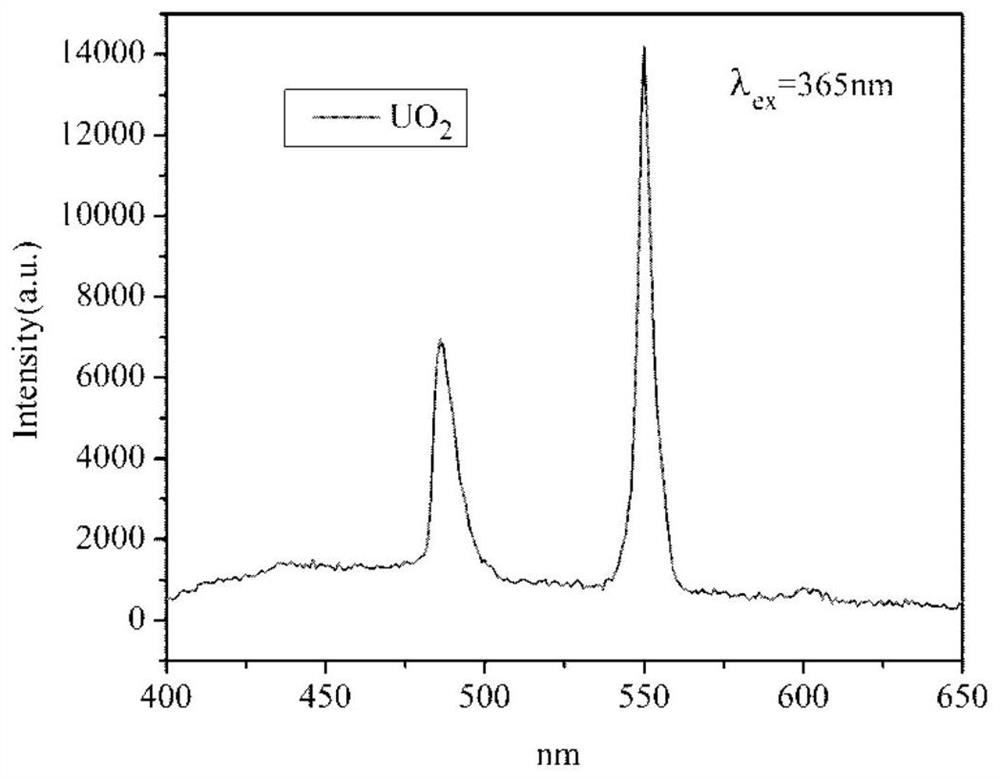

[0034] The purity is 99.99% UO 2 Raw materials and 99.9% Al 2 o 3 The raw materials are mixed and ground according to the molar ratio of 76.9:23.1, and the UO 2 -Al 2 o 3The raw materials are pressed and formed into 18×40mm dense cylindrical pellets; the cylindrical pellets are put into a tungsten crucible, the tungsten crucible is placed in a graphite crucible, and the graphite crucible is sealed; the graphite crucible is placed in the induction copper of a high-frequency induction heating device In the middle of the coil, the induction copper coil is fed with circulating cooling water to take away the heat of the system and maintain the temperature balance of the system; the inside of the heating furnace is filled with heat insulating powder to keep warm, and Ar / H2 (5% vol.) is introduced to start the induction heating device. Use high-frequency induction heating to raise the temperature to 2600°C, keep it warm for 12 hours, fully melt the uranium dioxide raw material, c...

example 2

[0036] The purity is 99.99% UO 2 Raw materials and 99.9% Al 2 o 3 The raw materials are mixed and ground according to the molar ratio of 77.2:22.8, and the UO 2 -Al 2 o 3 The raw materials are pressed and formed into 18×40mm dense cylindrical pellets; the cylindrical pellets are put into a tungsten crucible, the tungsten crucible is placed in a graphite crucible, and the graphite crucible is sealed; the graphite crucible is placed in the induction copper of a high-frequency induction heating device In the middle of the coil, circulating cooling water is introduced into the induction copper coil to take away the heat of the system and maintain the temperature balance of the system;

[0037] Fill the inside of the heating furnace with insulation powder to keep it warm, and pass Ar / H 2 (5% vol.), start the induction heating device, use high-frequency induction heating to raise the temperature to 2600 ° C, keep it for 12 hours, fully melt the uranium dioxide raw material, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com