Self-propelled daylily picking machine

A technology of daylily and picking machines, which is applied to harvesters, agricultural machinery and implements, applications, etc., can solve the problems of high labor intensity, heavy work, short-term biological characteristics, etc., and achieve the effect of improving picking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below in conjunction with illustrations and specific embodiments.

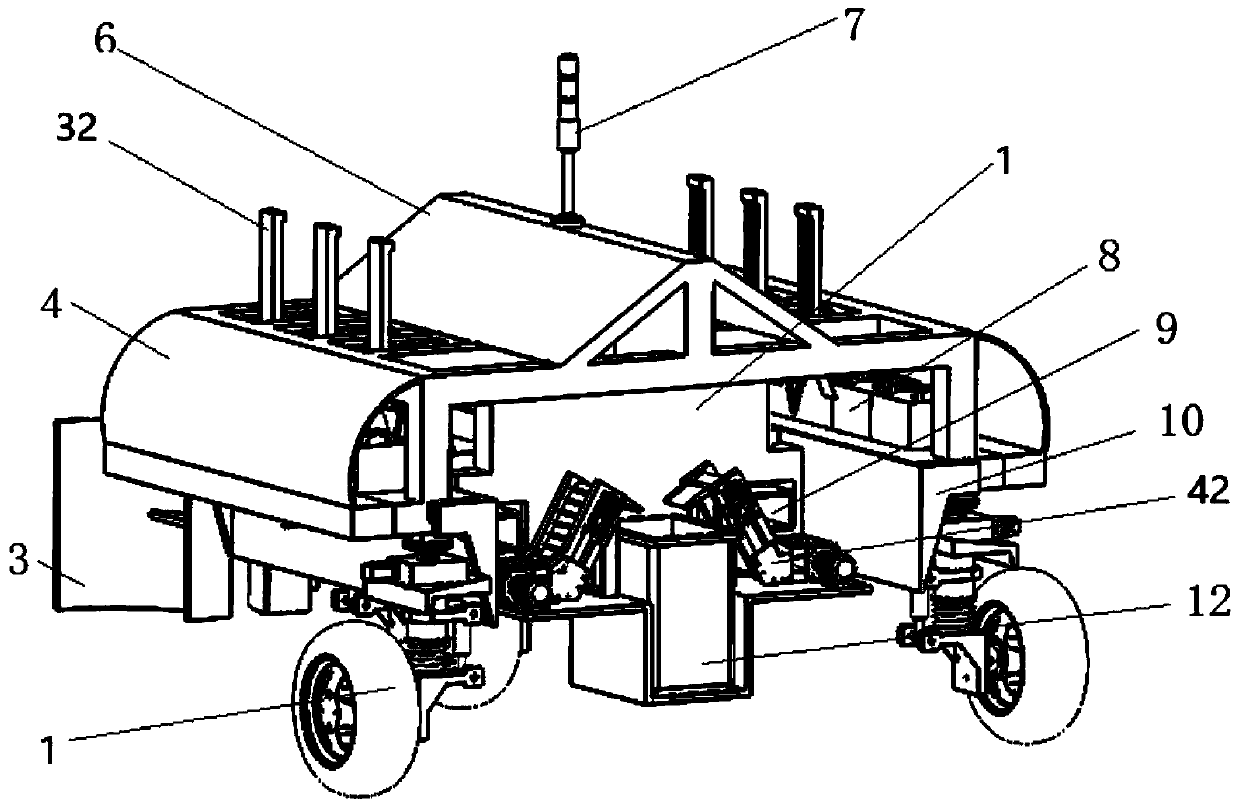

[0033] Such as Figure 1 to Figure 5 As shown, a kind of self-propelled day lily picking machine proposed by the present invention comprises a main body frame 1, and the main body frame 1 is provided with a traveling mechanism, a folding group plate, a picking mechanism, and a collecting mechanism.

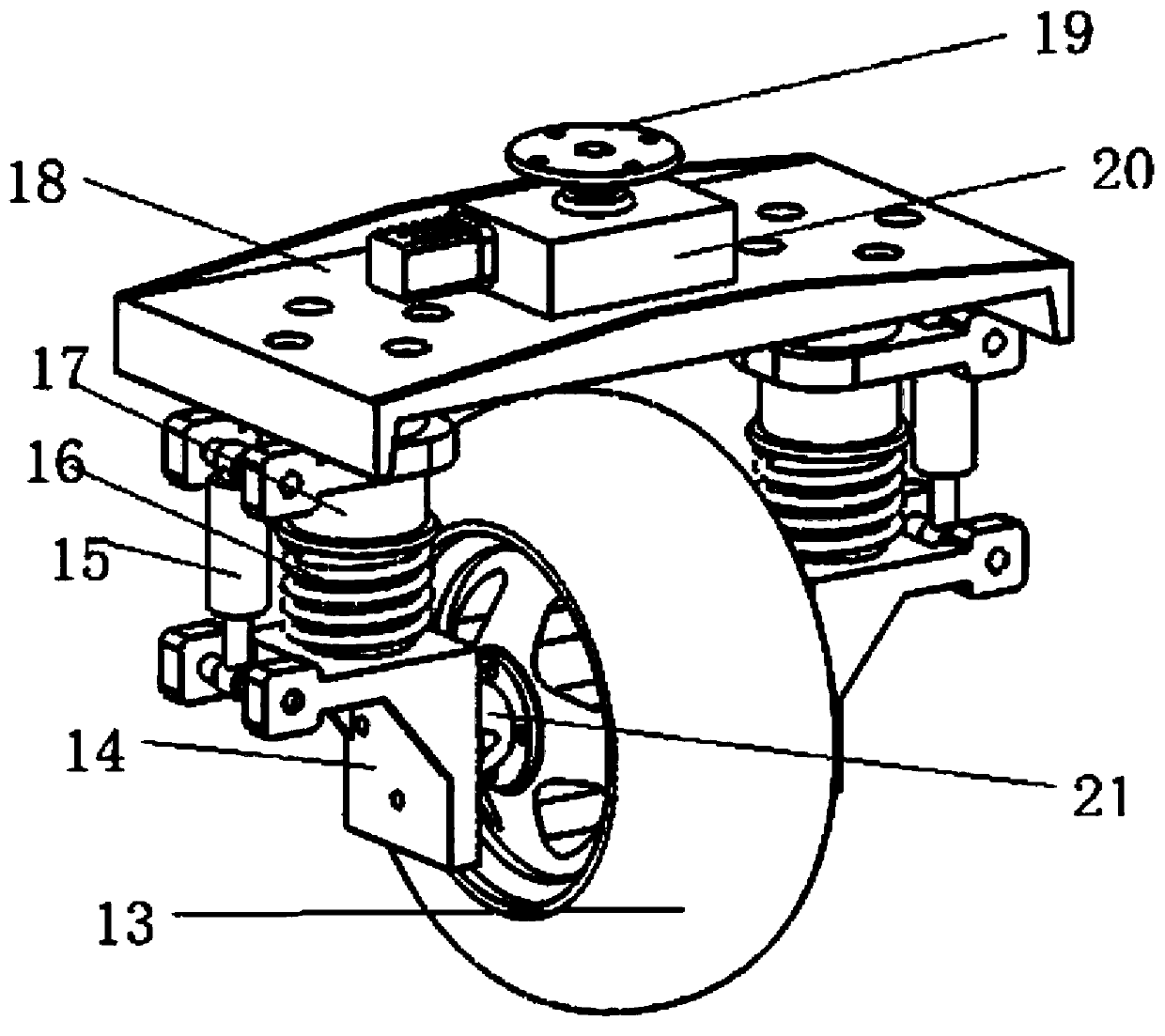

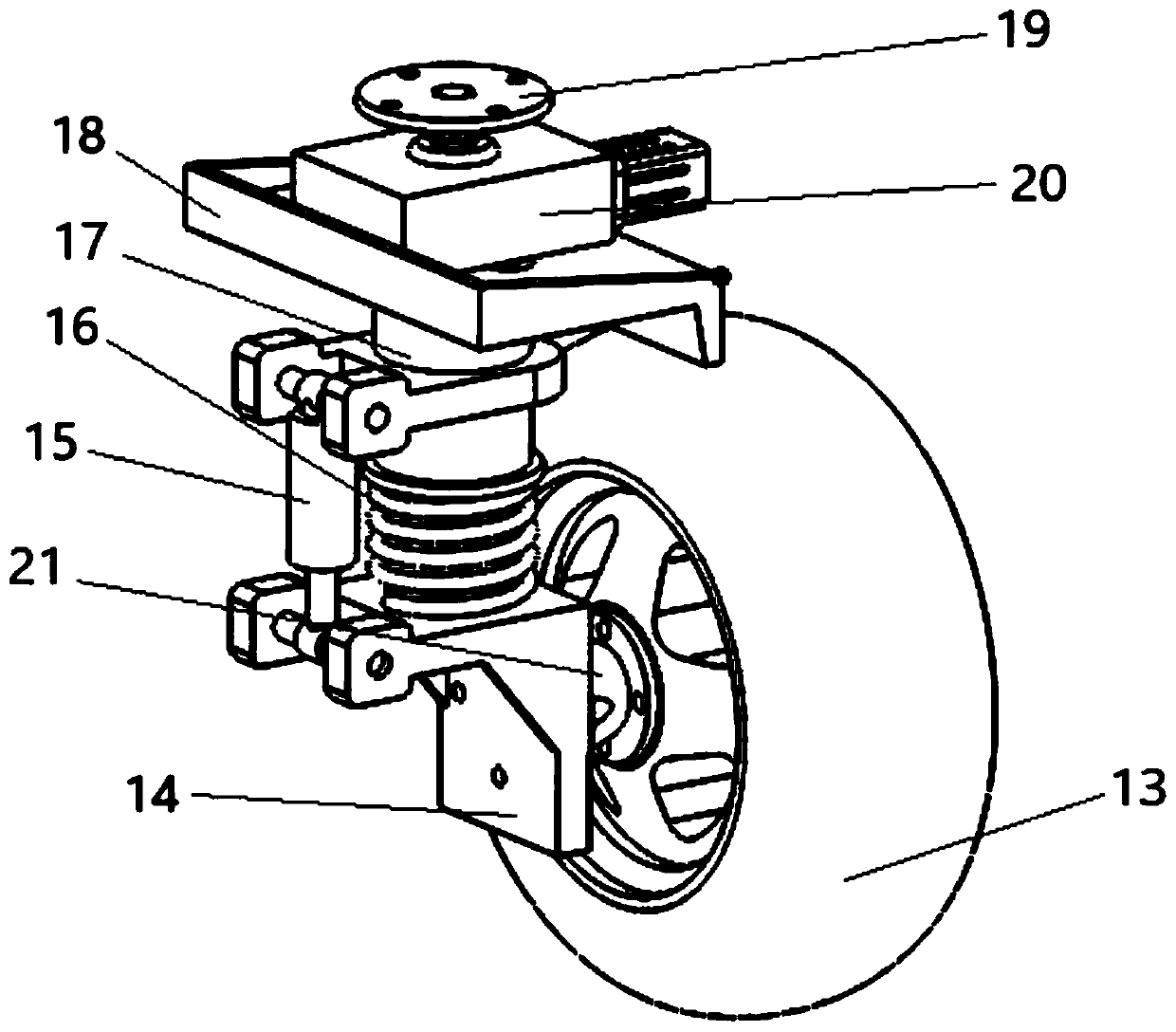

[0034] Wherein the traveling mechanism comprises the road wheel 13 that is arranged on the main body frame 1 and is built-in with the wheel hub motor, is arranged on the independent steering assembly that drives the road wheel 13 to turn between the road wheel 13 and the main body frame 1, and the independent steering assembly includes the wheel hub with the road wheel 13 The double-ended connecting flange 21 connected to the motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com