Power nitrogen gas cylinder for puncturing electric shock bombs in purely-mechanical structure manner

A purely mechanical, electric shock bomb technology, applied in compressed air guns, weapons without explosives, weapon types, etc., can solve the problem of complicated approval process for use, and achieve the effect of reducing procedures and application scenarios.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

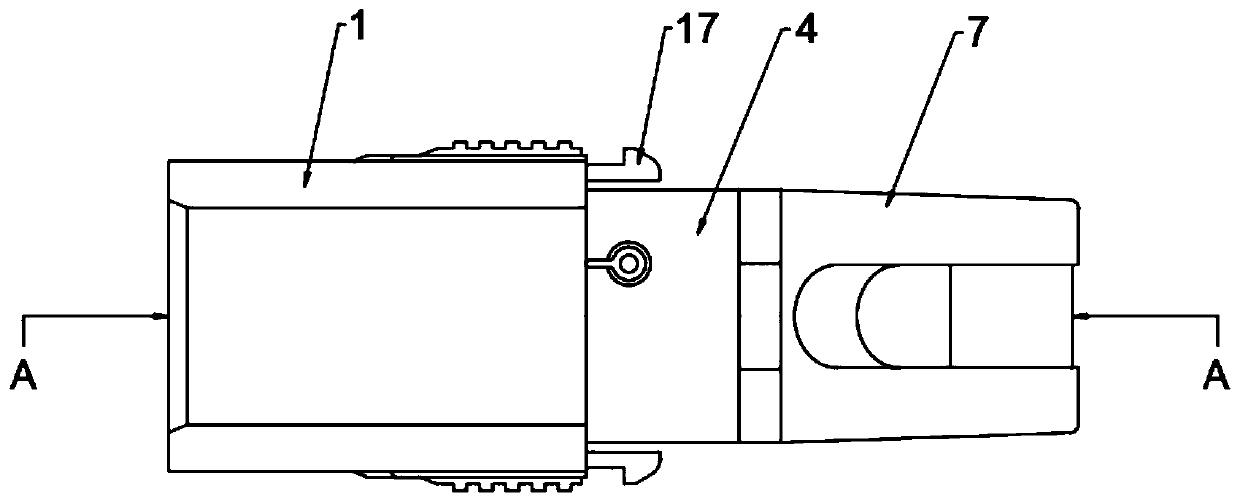

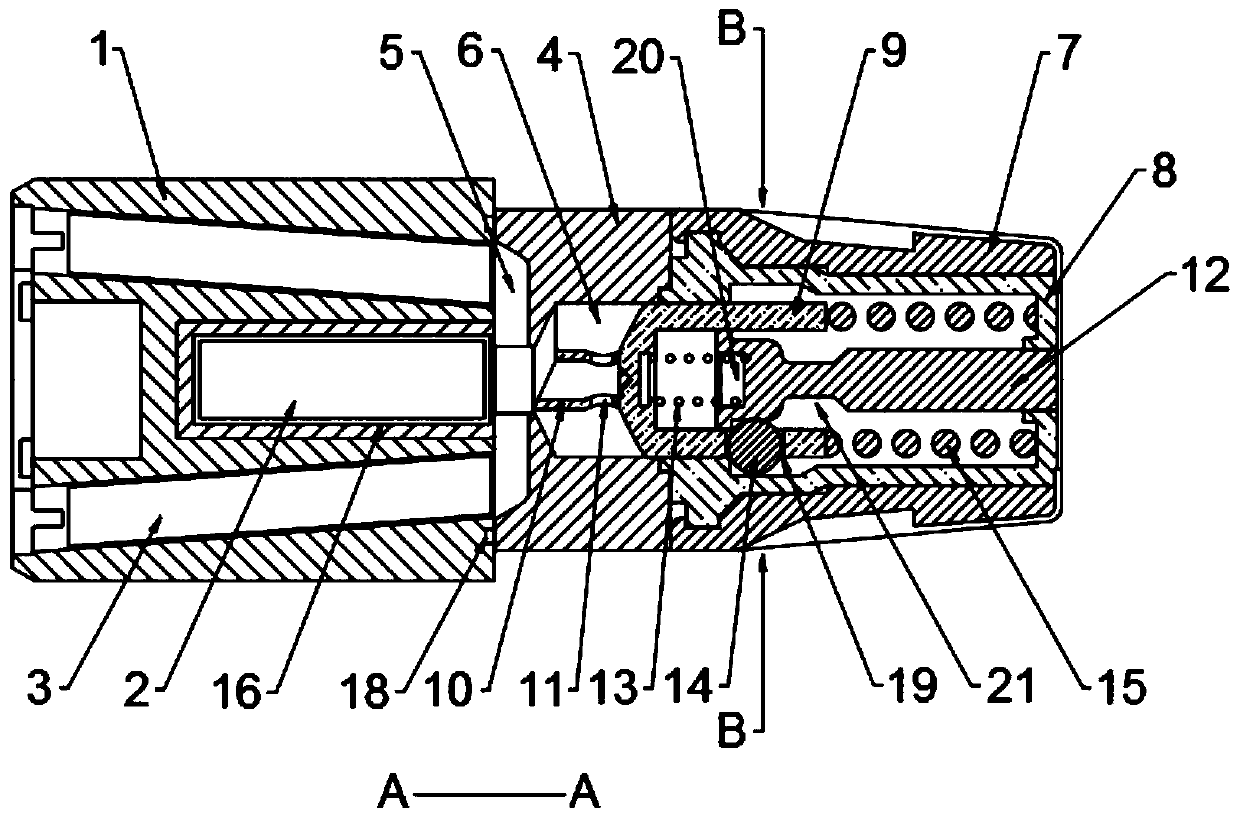

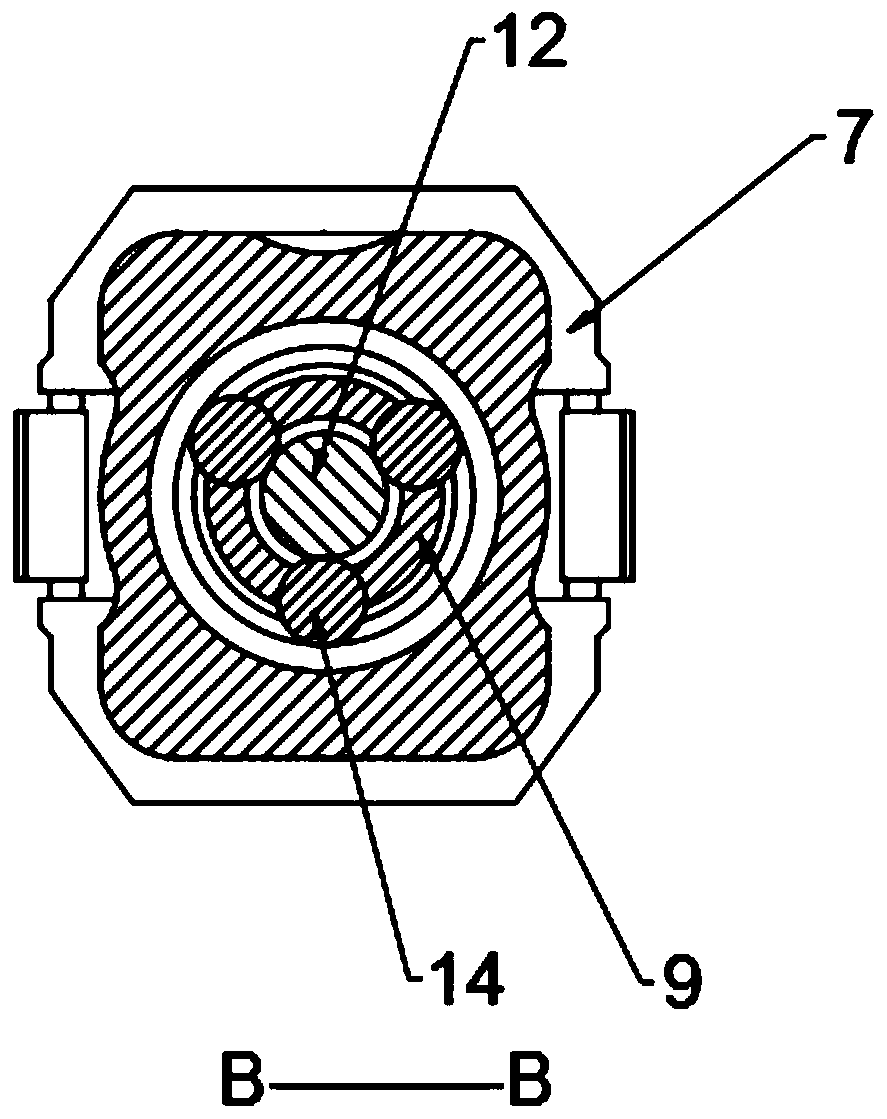

[0023] Embodiment one, by figure 1 , figure 2 with image 3 Given, the present invention includes a front-end housing 1, a high-pressure gas cylinder 2 is embedded in the center of the front-end housing 1 for providing power gas, and the two sides of the high-pressure gas cylinder 2 are provided with a flying needle air passage 3 relative to the inside of the front-end housing 1 for use in In order to accommodate the gas needle, one end of the front shell 1 is connected to the tail air passage connecting warehouse 4, and the connecting end of the tail air passage connecting warehouse 4 and the front shell 1 is provided with a gas channel 5, which is used to transport the gas of the high-pressure gas cylinder 2 to the aircraft. Needle air channel 3, gas channel 5 communicates with flying needle air channel 3, one end of gas channel 5 is connected with movable chamber 6 for the movement of puncture needle 9, the end air channel connection chamber 4 far away from gas channel 5 ...

Embodiment 2

[0024] Embodiment 2, on the basis of Embodiment 1, an installation groove 16 is opened inside the front shell 1 relative to the connection of the high-pressure gas cylinder 2 to facilitate the installation of the high-pressure gas cylinder 2 .

Embodiment 3

[0025] Embodiment 3, on the basis of Embodiment 1, the front housing 1 is externally connected with connecting claws 17 for easy connection, so as to facilitate the connection of the device with corresponding equipment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com