Processing technology and system for producing concrete aggregate by using complex material source

A technology of concrete aggregate and processing technology, which is applied in the direction of climate sustainability, sustainable waste treatment, grain treatment, etc., and can solve the problems of unbalanced aggregate gradation of finished products and difficulty in meeting the requirements of hydraulic construction concrete.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

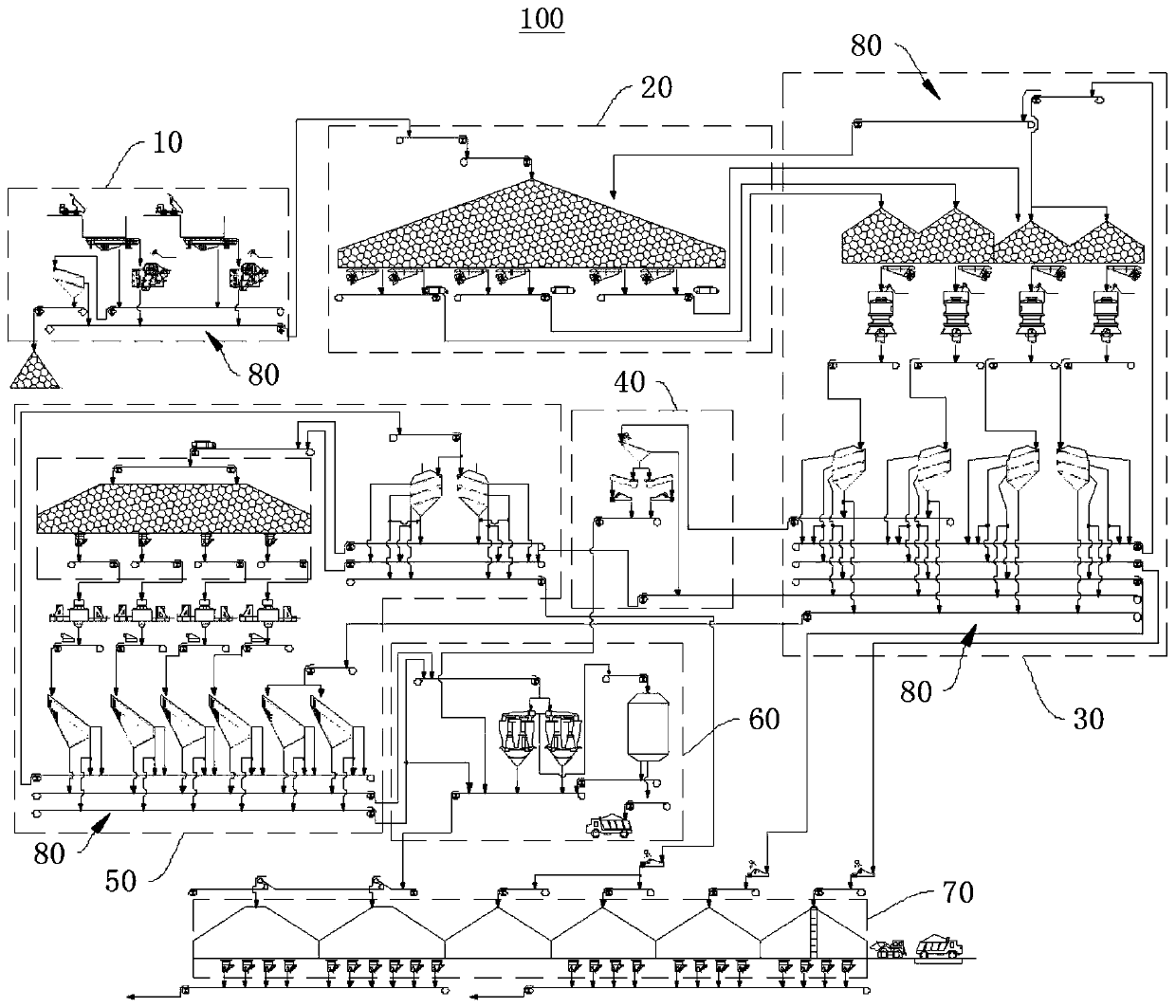

[0036] see figure 1 , figure 1 It is a schematic structural diagram of a processing system 100 for producing concrete aggregates using complex material sources according to the first embodiment of the present invention.

[0037] The first embodiment of the present invention provides a concrete aggregate processing system 100 using complex material sources to produce concrete aggregates. The effect is good, the gradation of the finished aggregate produced is continuous, and the utilization rate of the material source is high.

[0038] The following will specifically introduce the structural composition, working principle and beneficial effects of the processing system 100 for producing concrete aggregates using complex material sources provided by the first embodiment of the present invention.

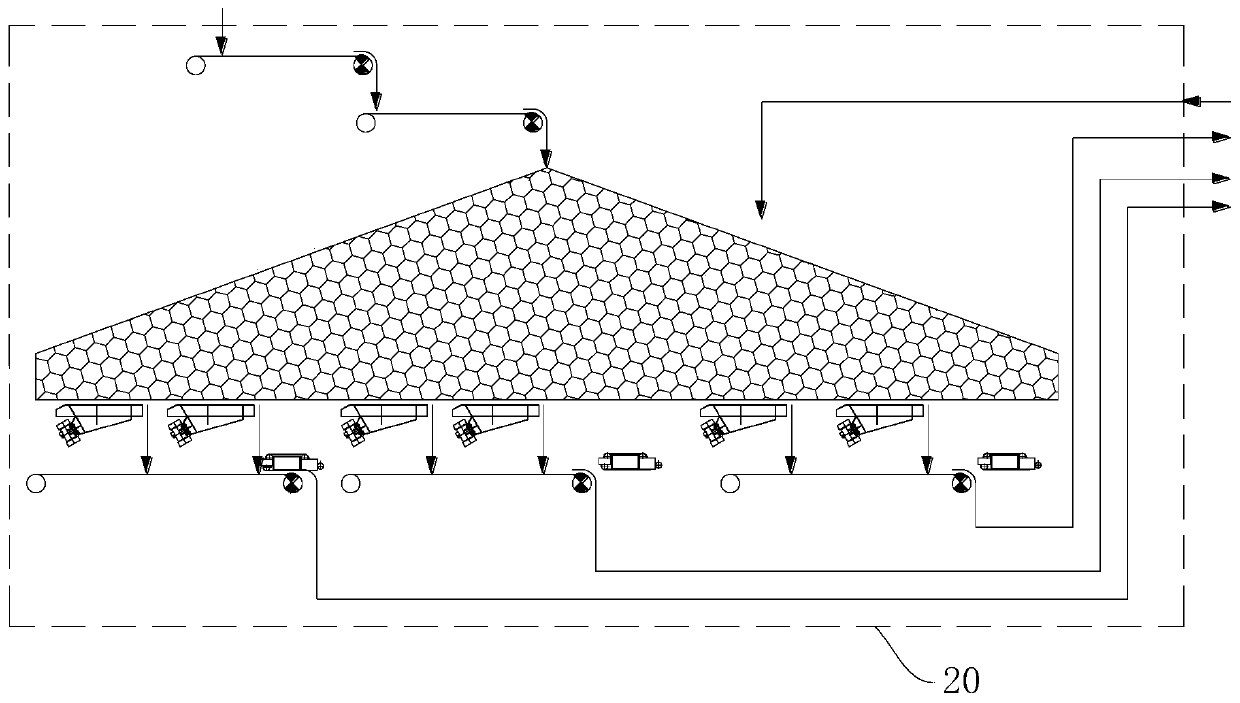

[0039] see figure 1 , figure 2 , image 3 and Figure 4 , figure 2 It is a schematic structural diagram of the primary crushing device 10 of the concrete aggregate processing s...

no. 2 example

[0074] see Figure 9 , Figure 9 It is a schematic flowchart of the process for producing concrete aggregates using complex material sources according to the second embodiment of the present invention.

[0075] It should be noted that the processing technology for producing concrete aggregates using complex material sources provided in this embodiment is applied to the processing system 100 for producing concrete aggregates using complex material sources in the above embodiment, and its basic principles and technical effects are the same as those of the above implementation For the sake of brief description, for parts not mentioned in this embodiment, reference may be made to the corresponding content in the foregoing embodiments.

[0076] The processing technology for producing concrete aggregates using complex material sources includes:

[0077] Step S101: Coarsely crush the excavated materials to form coarse crushed materials. In this step, before coarsely crushing the ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com