Automatic conveying and trimming device for plastic film roll

A technology of automatic conveying and plastic film, applied in metal processing and other directions, can solve the problems of easy film breaking, uneven ends of film rolls, affecting the appearance of products, etc., and achieve the effect of keeping the end face neat.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

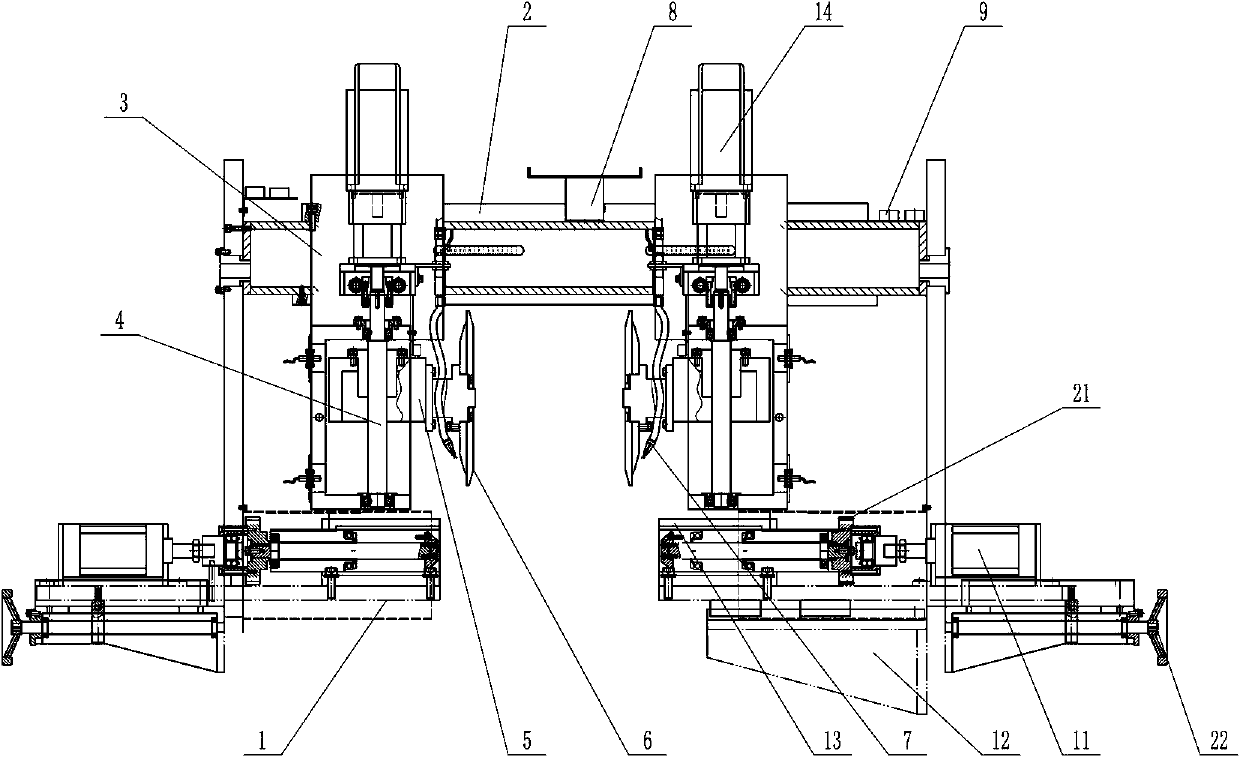

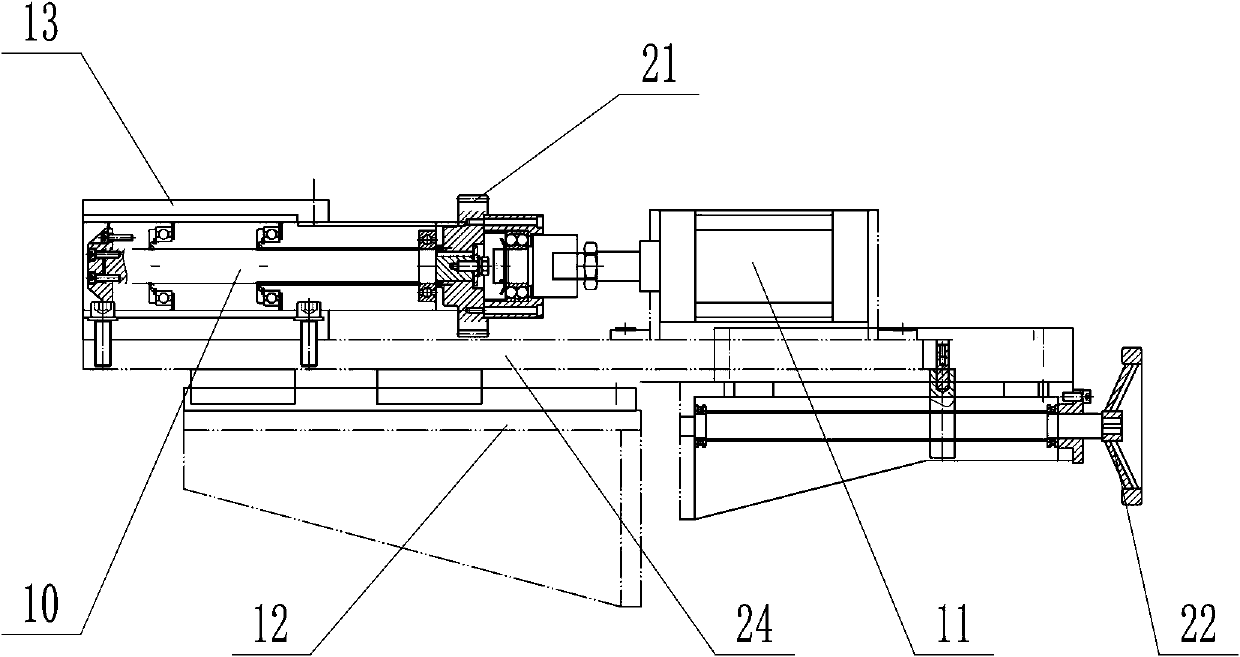

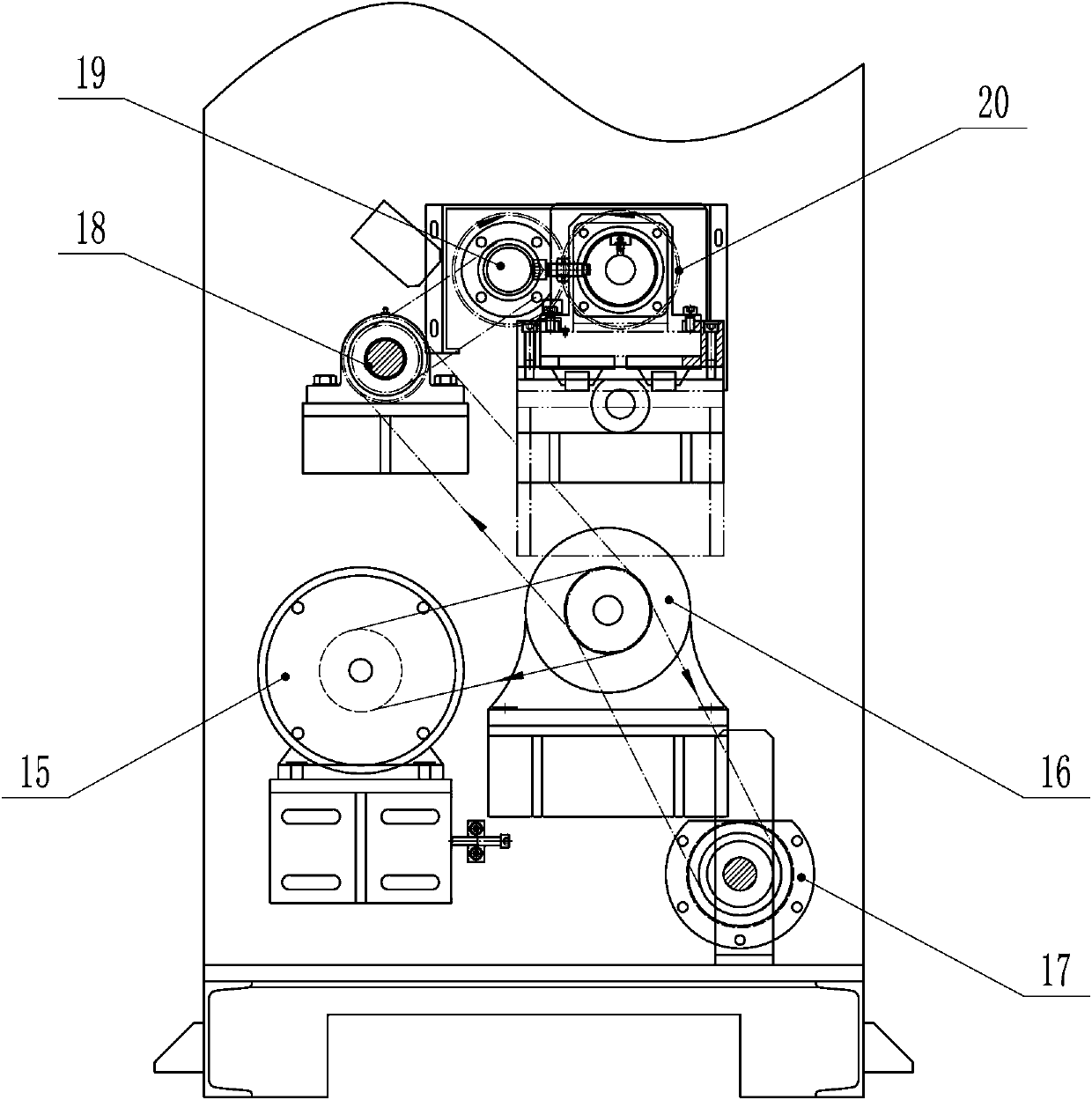

[0023] as attached Figure 1-5 As shown, the present invention includes a clamping device for clamping the paper tube, a cutting device arranged above the clamping device, and a conveying device for transporting the paper tube into the clamping device for cutting.

[0024] The clamping device includes a base 12, a base plate 24 arranged on the base 12 through a linear slide rail, a support cylinder 13 fixed on the base plate 24, a top shaft 10 nested in the support tube 13, and a rear shaft 10 arranged behind the top shaft 10. In order to drive the driving device 11 to move the top shaft 10 back and forth, a bottom plate moving device is also provided. The base plate moving device is a lead screw nut pair, which is fixedly connected with the base plate 24, the lead screw passes through the lead screw nut, and a handwheel 22 is arranged at one end of the lead screw. A driven gear 21 is also arranged on the top shaft 10, and the driven gear 21 drives it to rotate through a tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com