Machine housing and rotating shaft assembling device

A technology for assembling equipment and casings, applied in the field of casing and shaft assembly equipment, can solve problems such as low efficiency and uneven dispensing, and achieve the effects of reducing noise pollution, good product consistency, and improving working environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] For the motor with outer rotor structure, its rotating shaft is fixedly arranged with the casing. The existing technology is to manually put the rotor casing and the rotating shaft on the press-fitting mold, and manually apply glue to the corresponding position of the shaft before putting the shaft. It is not uniform, and a 1-ton hydraulic press is used for press-fitting. There is no isolation between the operator and the press-fitting mold, and there is a certain degree of danger.

[0036] In order to solve the above technical problems, this embodiment provides a casing and shaft assembly equipment, the casing and shaft assembly equipment is based on the existing press-fit structure, adding automatic feeding, retrieving and dispensing mechanisms , which can realize the automatic operation of feeding, dispensing, pressing and retrieving, and isolate the possible damage to the human body caused by the press. The following diagrams are used to illustrate:

[0037] Such a...

Embodiment 2

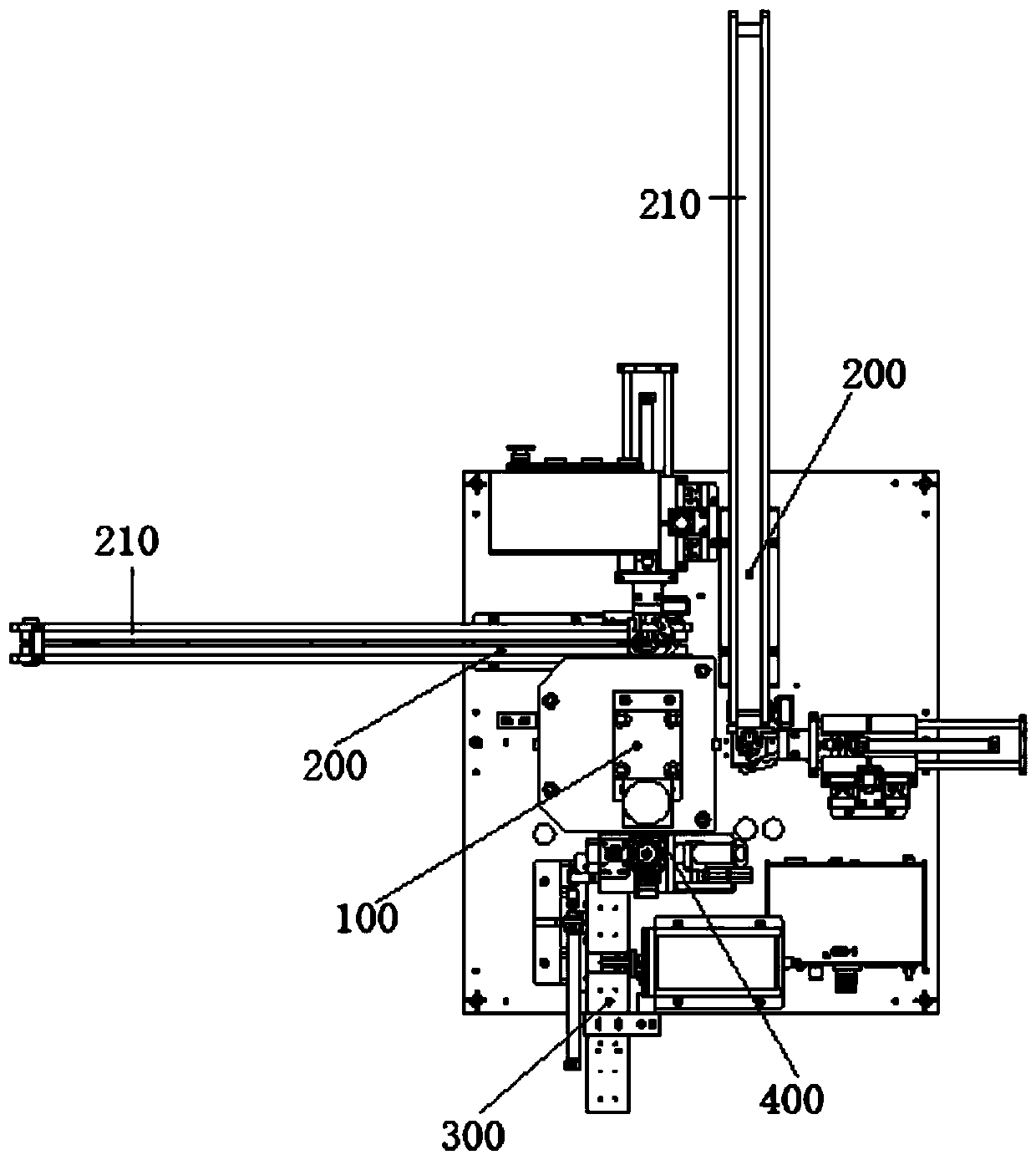

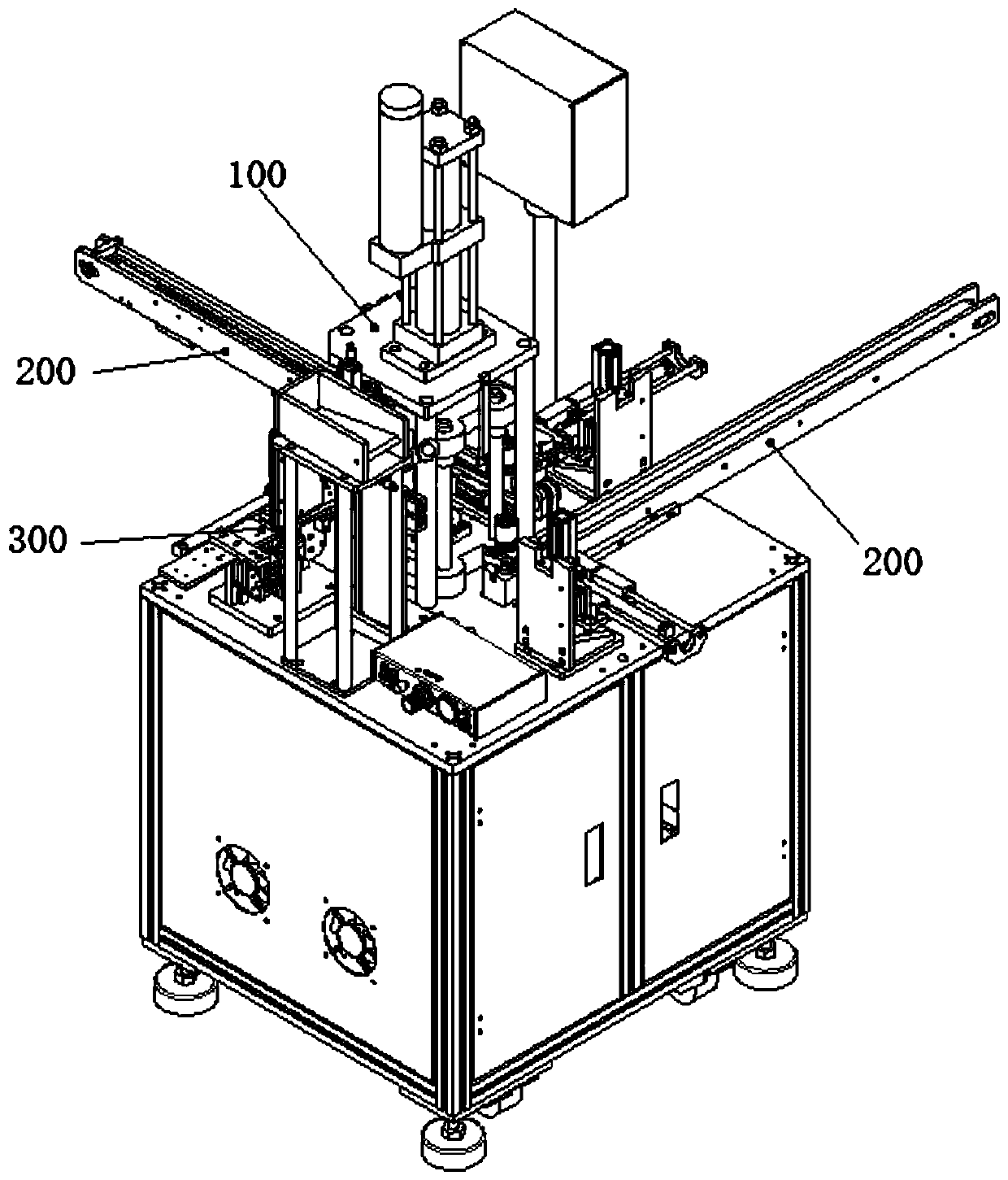

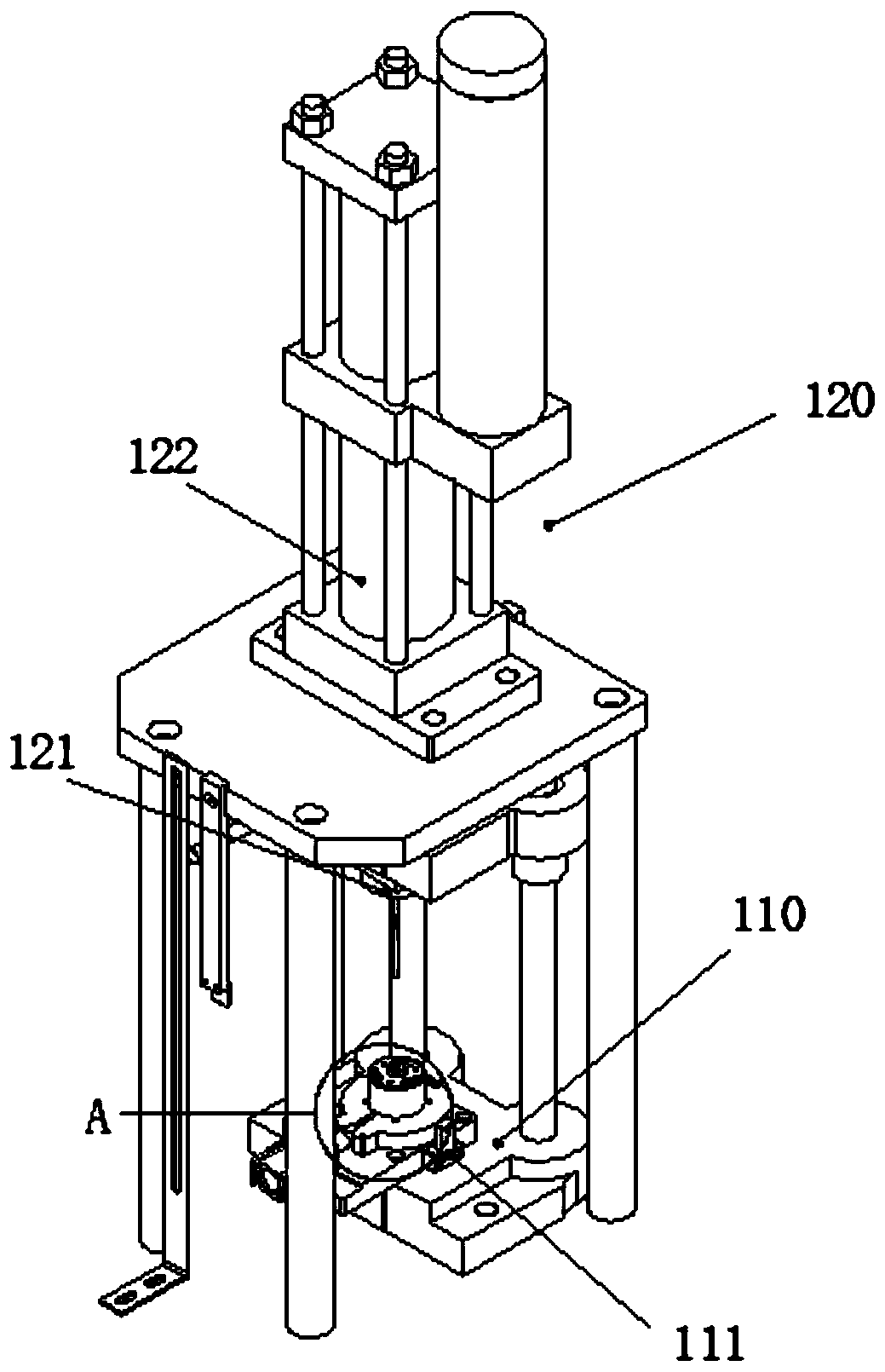

[0054] Such as Figure 1-2 As shown, the casing and shaft assembly equipment provided in this embodiment also includes a press-fit structure 100 for pressing the shaft, and two sets of casing transmission structures 200, shaft delivery structures 300 and point fittings arranged around the press-fit structure 100 Glue structure 400.

[0055] The shaft feeding structure 300 provided in this embodiment includes a shaft hopper 310 with a bottom vertical output shaft and a shaft feeding assembly 320 located below the shaft hopper 310 and used for clamping the shaft to extend between the pressing assembly 120 and the base 110 .

[0056] The shaft sending assembly 320 of the shaft sending structure 300 includes a second pneumatic finger 321 and a second two-axis transmission component 322 composed of a lifting cylinder and a traverse cylinder. After the rotating shaft falls from the shaft hopper 310, the lower end of the rotating shaft is exposed to the end of the blanking channel 3...

Embodiment 3

[0061] Such as Figure 1-2 As shown, the casing and shaft assembly equipment provided in this embodiment also includes a press-fit structure 100 for pressing the shaft, and two sets of casing transmission structures 200, shaft delivery structures 300 and point fittings arranged around the press-fit structure 100 Glue structure 400.

[0062] The shaft feeding structure 300 provided in this embodiment includes a shaft hopper 310 with a bottom vertical output shaft and a shaft feeding assembly 320 located below the shaft hopper 310 and used for clamping the shaft to extend between the pressing assembly 120 and the base 110 .

[0063] The shaft sending assembly 320 of the shaft sending structure 300 includes a second pneumatic finger 321 and a second two-axis transmission component 322 composed of a lifting cylinder and a traverse cylinder. After the rotating shaft falls from the shaft hopper 310, the lower end of the rotating shaft is exposed to the end of the blanking channel 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com