A pre-leaf-picking treatment mechanism for high-protein feed used in large-scale dairy farming

A technology for high-protein feed and dairy cows, applied in applications, picking machines, harvesters, etc., can solve problems affecting the economic benefits of tree leaves, low picking efficiency, and high labor intensity, and achieve ingenious structure, improved picking efficiency, and automation high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

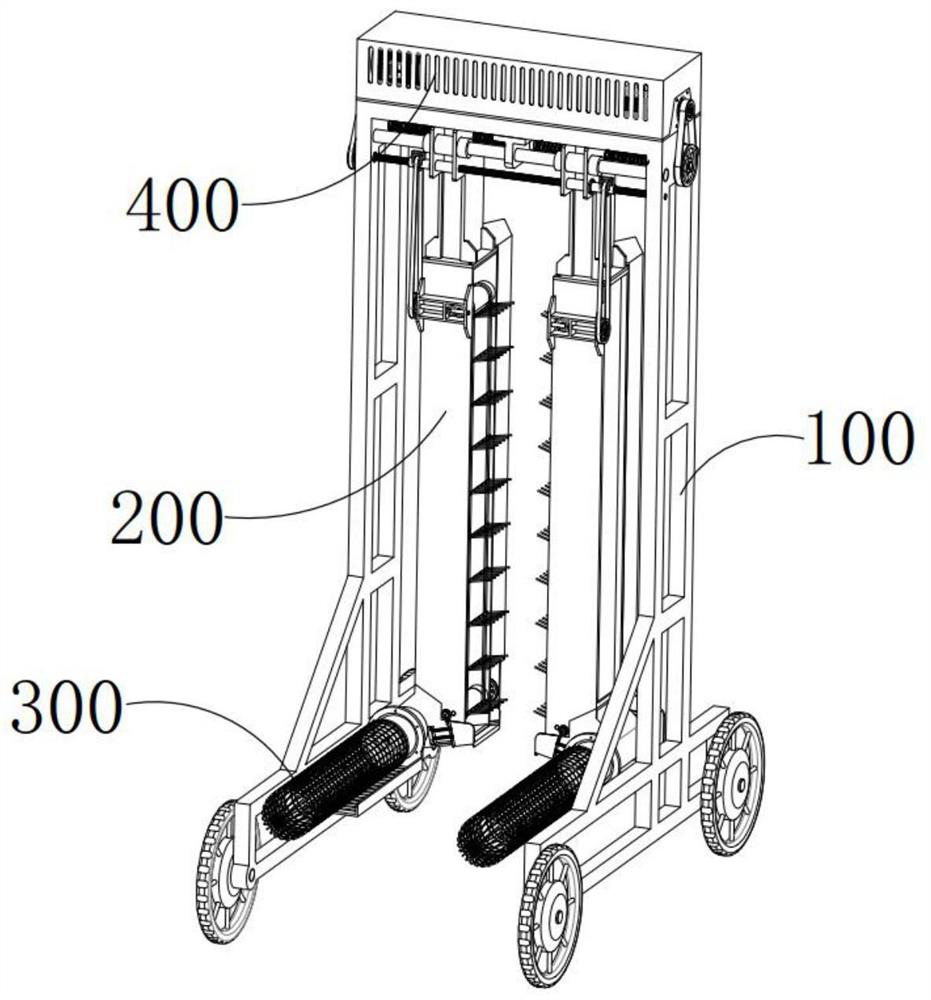

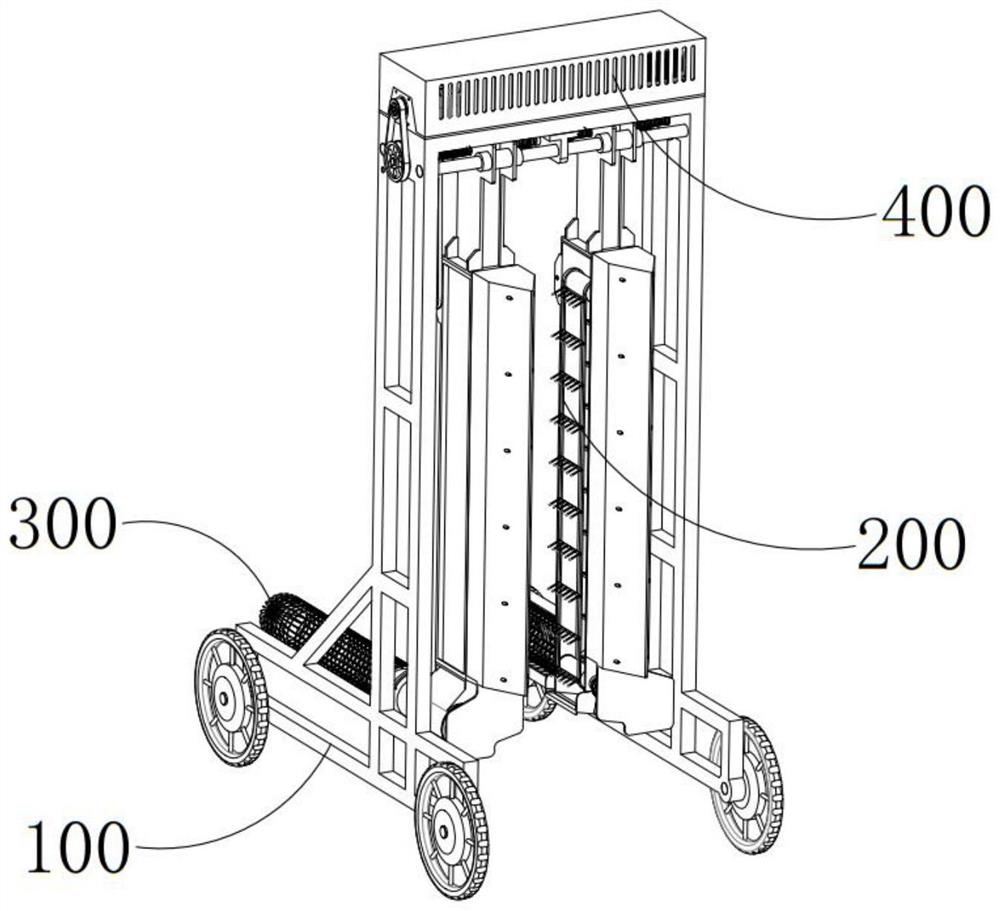

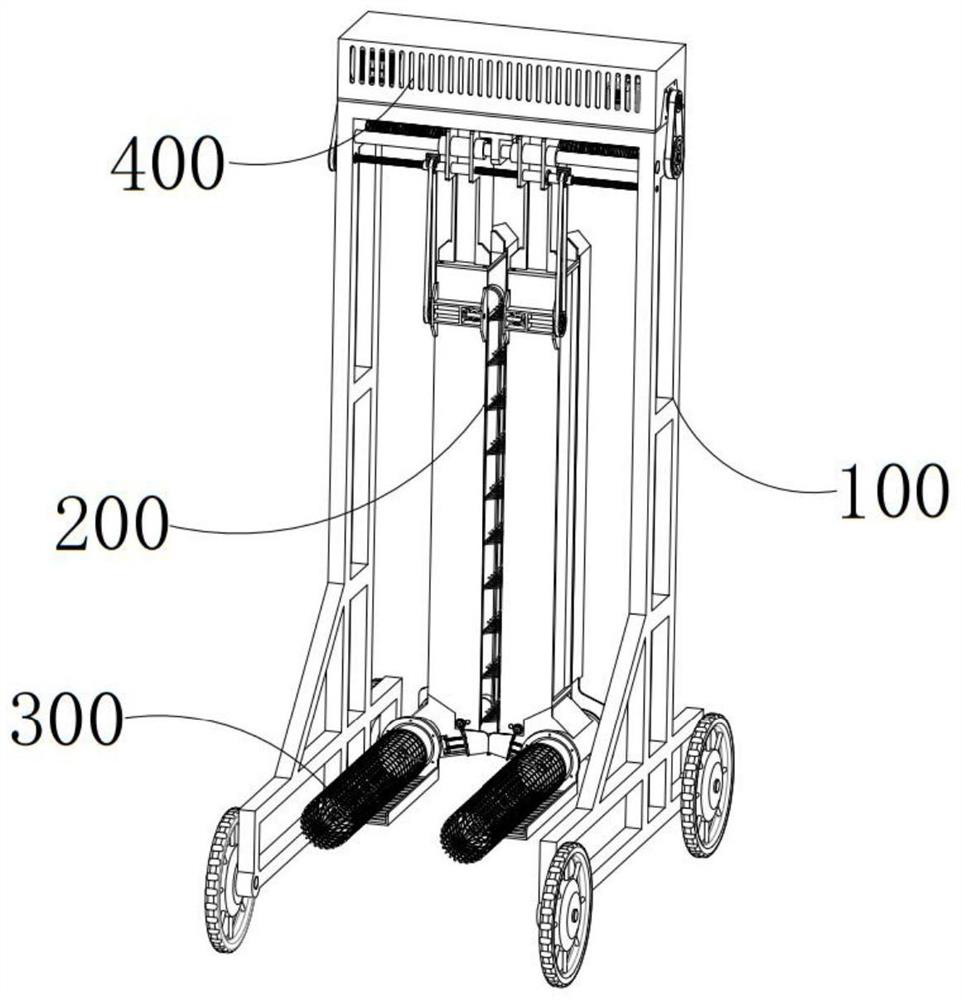

[0044] see Figure 1-19, a chain-type tree leaf automatic picker, which includes a mounting frame 100, a picking device 200, a collecting device 300 and a power drive device 400, the picking device 200 is used to pick the leaves of the tree, and the collecting device 300 is used to pick the leaves of the tree. The leaves picked by the picking device 200 are collected, the power drive device 400 can transmit power to the picking device 200 and drive the picking device 200 to operate normally, and the picking device 200 can transmit power to the collecting device 300 and drive the collecting device 300 In normal operation, the mounting frame 100 includes two rectangular horizontal frames 101 arranged at intervals, and two rectangular vertical frames 102 arranged at intervals. The middle position is fixedly connected, the vertical frame 102 and the horizontal frame 101 form an inverted T-shaped structure, the upper ends of the two vertical frames 102 are fixedly connected by a co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com