Composite light pile group pile bearing capacity detection device, system and method

A bearing capacity and detection device technology, which is applied in the direction of measuring devices, using stable tension/pressure testing material strength, instruments, etc., can solve problems such as the detection of the bearing capacity of composite lightweight piles, and meet engineering testing requirements. Improve overall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

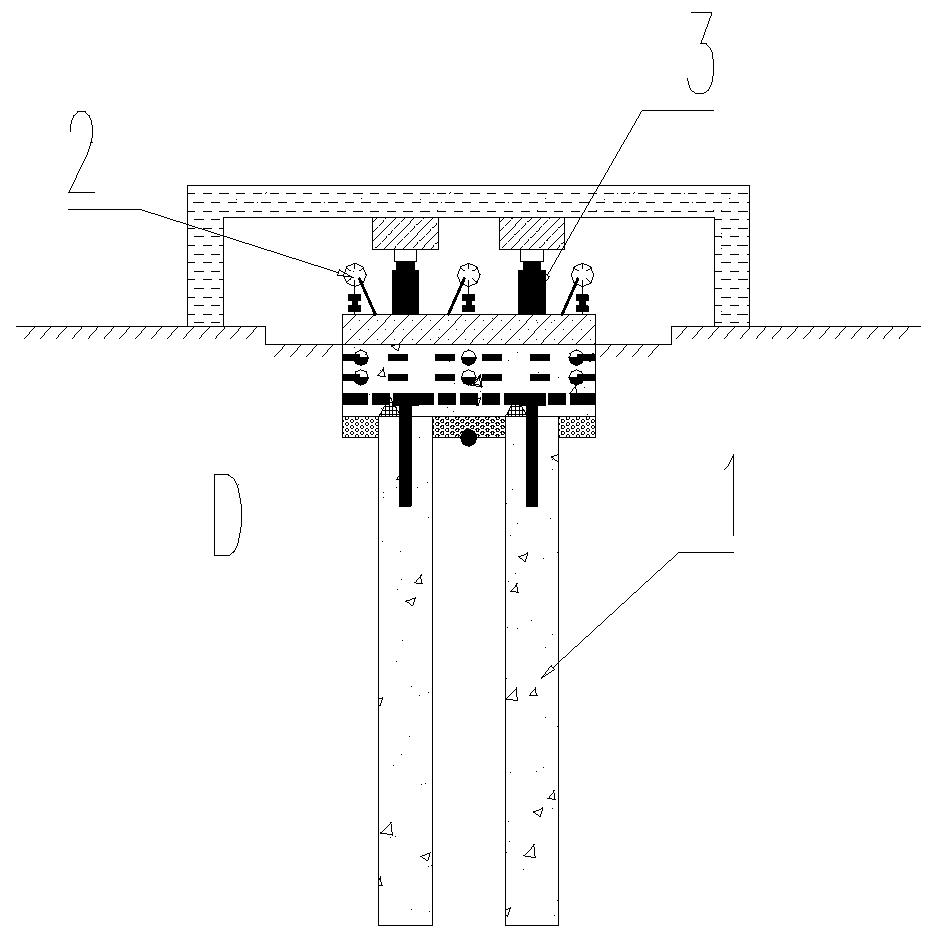

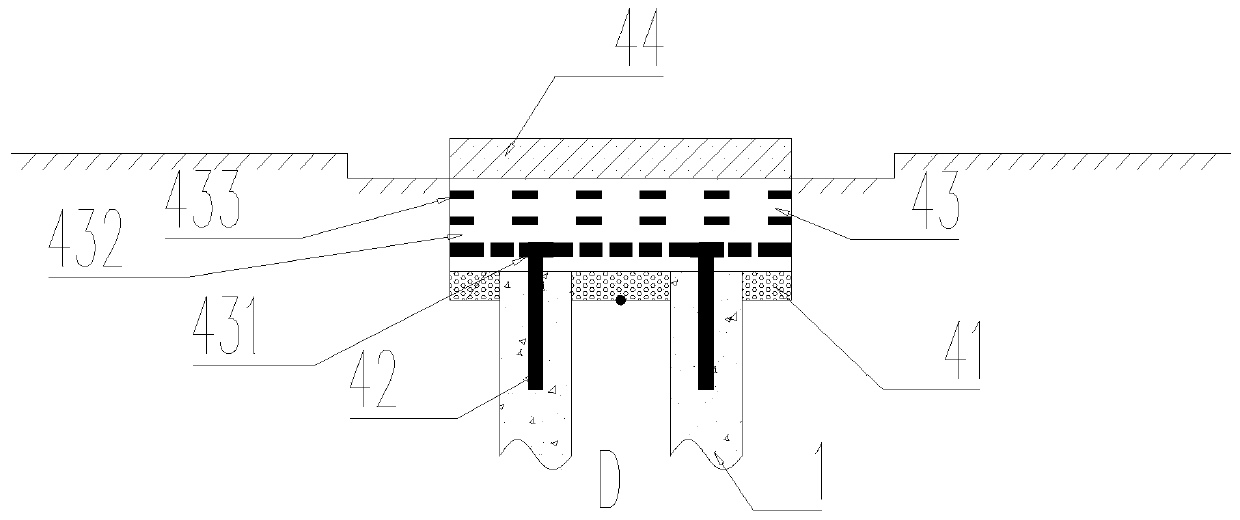

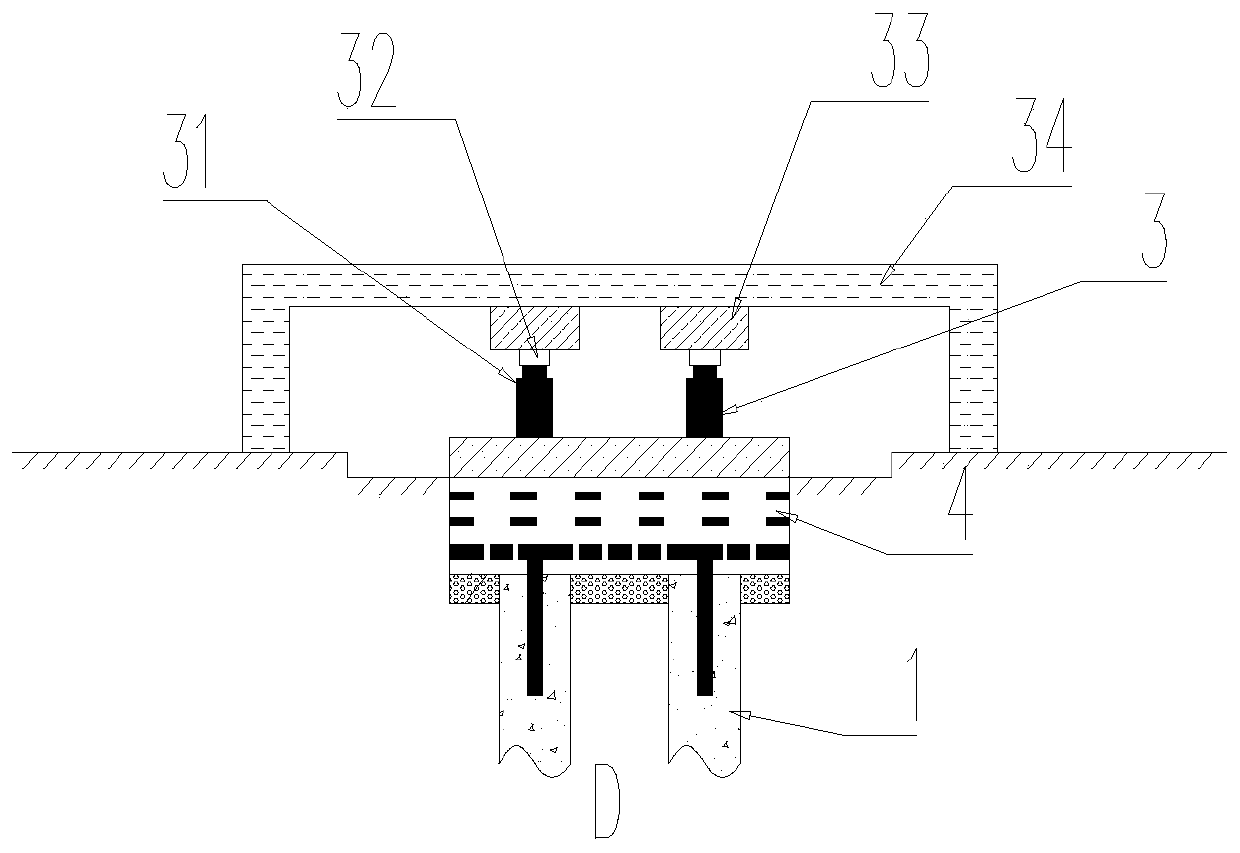

[0045] refer to figure 1 , the detection system for the bearing capacity of the composite lightweight pile group of the present invention includes a detection device and a composite lightweight pile group 1, the detection device includes a support subsystem 4, a loading subsystem 3, and a test subsystem 2, and the support subsystem 4 is composed of rough The sand cushion layer 41, the connecting steel bar 42, the lightweight subbase 43 and the bearing platform 44 are composed, the loading subsystem 3 is composed of the jack 31, the pressure sensor 32, the main beam 33 and the reaction device 34, and the testing subsystem 2 includes the dial indicator 21. Horizontal grid tension sensor 22, load sensor 23, earth pressure cell 24 and composite reinforced cage 7 dynamometer.

[0046] In the above scenario:

[0047] refer to figure 1 , figure 2, the thickness of the coarse sand cushion layer 41 in the support subsystem 4 is not less than 0.2m, and its function is to prevent the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com