Intelligent high-precision plasma cutting device and cutting method for ship maintenance

A cutting device, high-precision technology, applied in plasma welding equipment, metal processing equipment, welding equipment and other directions, can solve the problems of low cutting accuracy, difficult to carry, and unstable hand-held by operators, and achieves convenient carrying and position adjustment. The effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

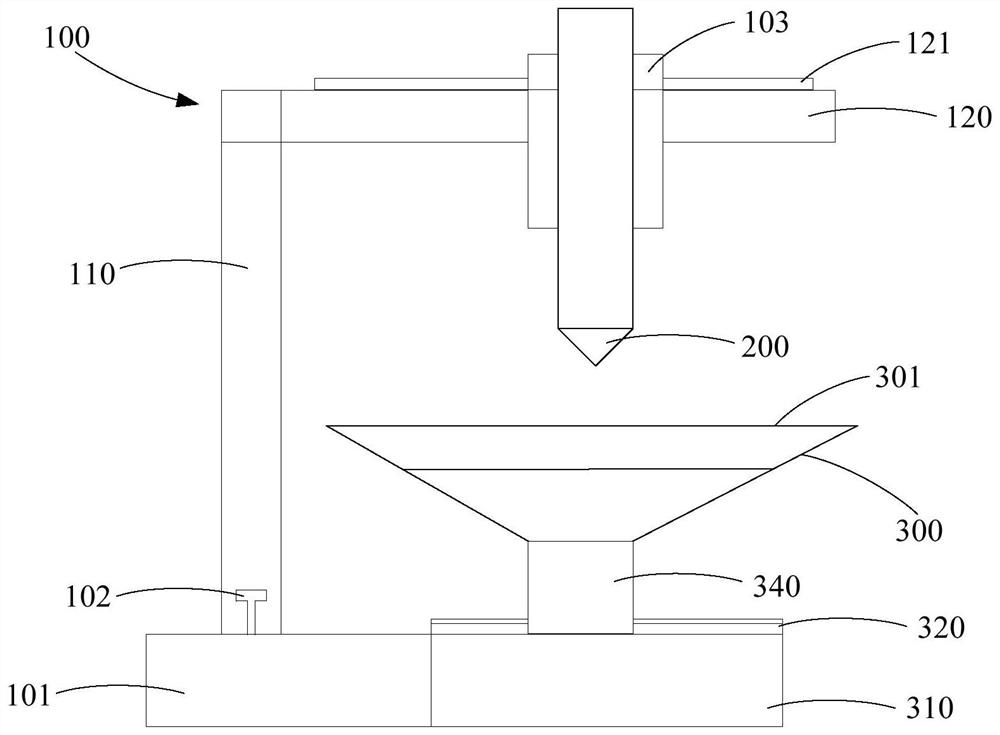

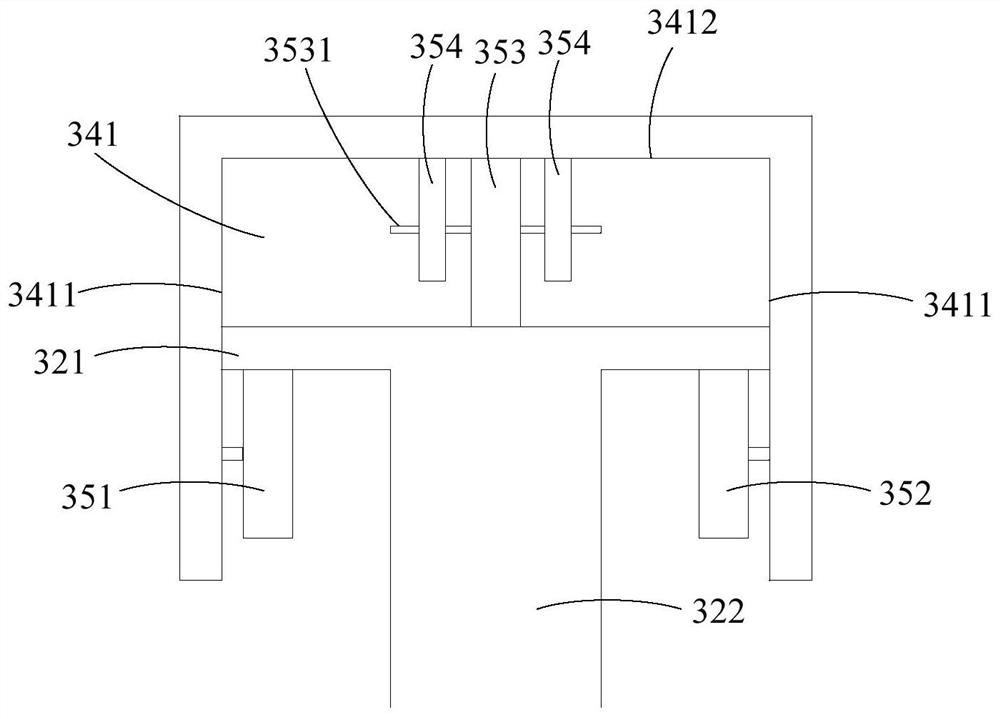

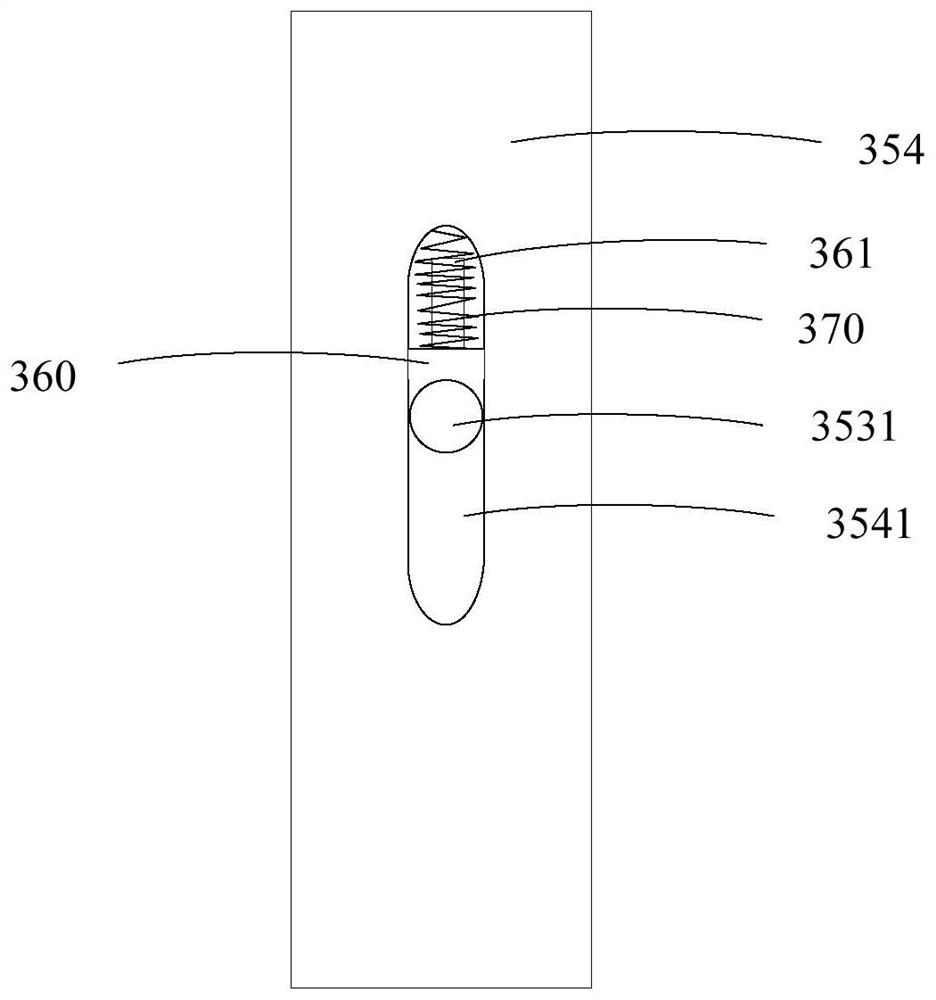

[0037] This application provides an intelligent high-precision plasma cutting device and cutting method for ship maintenance. By arranging a first support column 110 and a second support column 120 on the base 101, the second support column 120 is connected to the first support column 120. On the top of the support column 110, the first support column 110 is movably arranged along the first direction, the cutting head 200 is movably arranged on the second support column 120 along the second direction, and a rotating frame 300 is arranged below the cutting head 200, which rotates The rack 300 is rotatably arranged on the cutting head 200, which not only simplifies the structure of the plasma cutting device but also reduces the volume of the plasma cutting device, which is convenient for maintenance personnel to carry out when going out, and also ensures that the cutting head 200 can be stably and accurately aligned on the bearing surface The plate on 301 is cut.

[0038] In ord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com