Metal material compression creep testing device and measuring method thereof

A technology of compression creep and testing equipment, which is applied in the field of creep testing and testing of metal materials under compressive stress, and in the field of compression creep testing equipment for metal materials. Good performance and cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

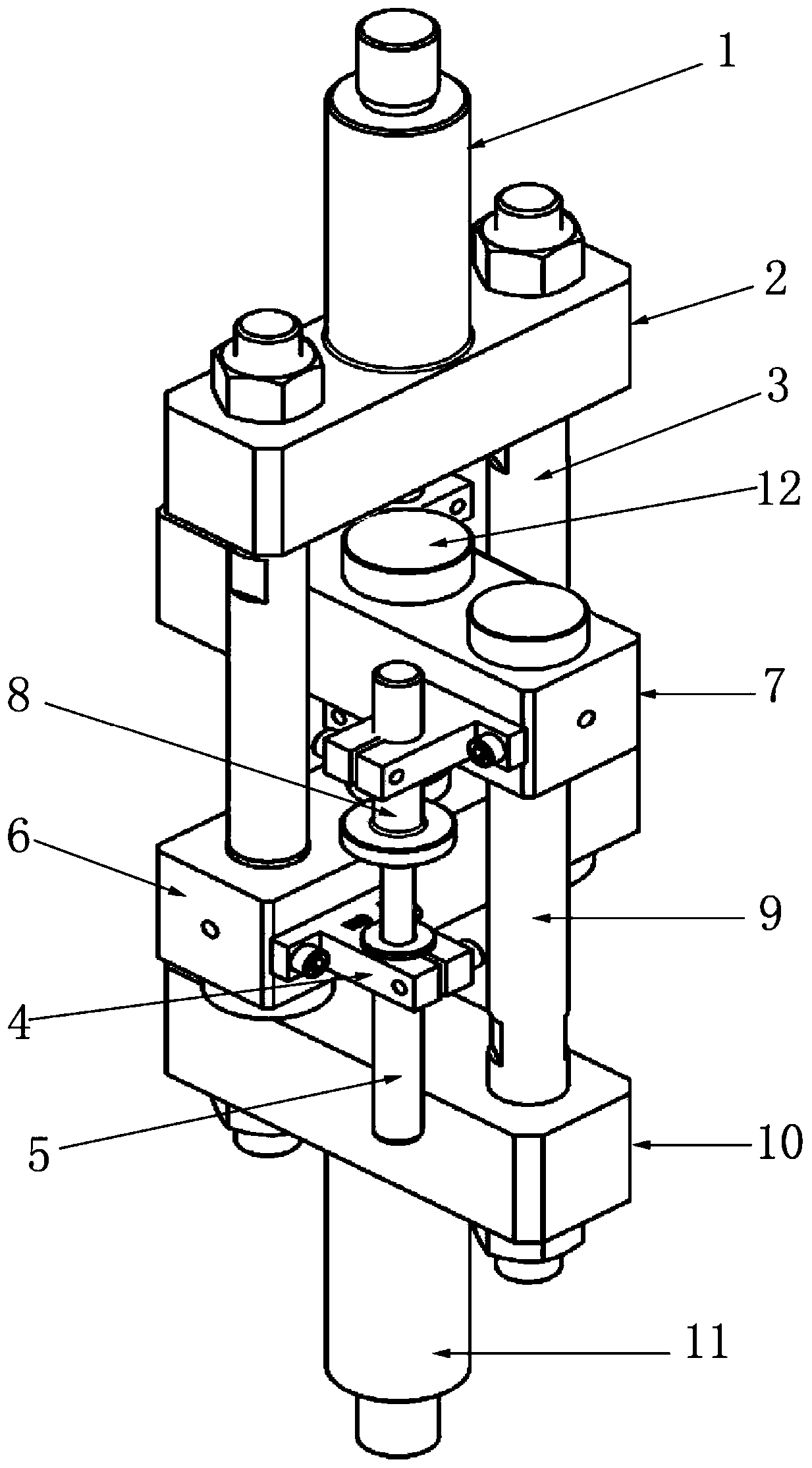

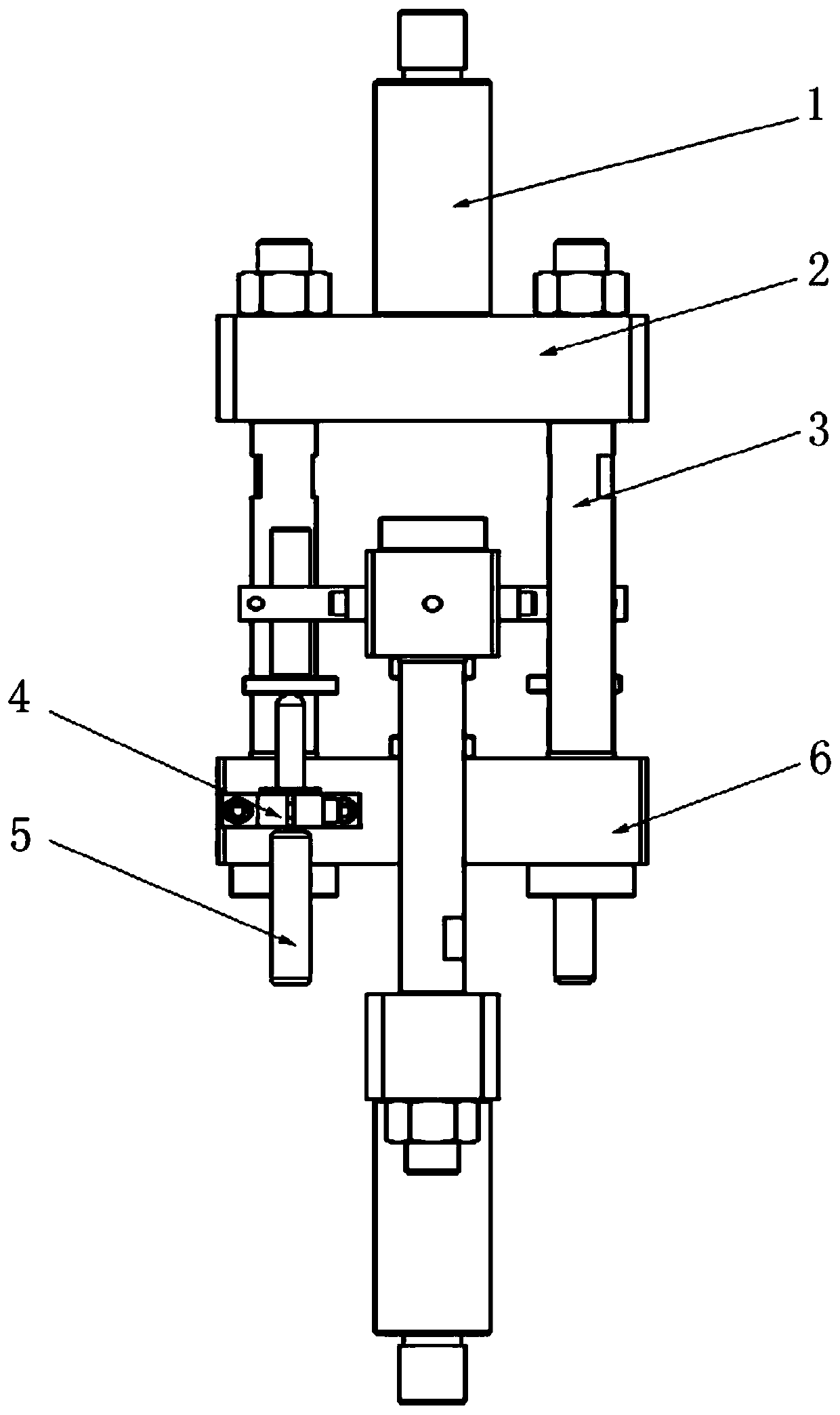

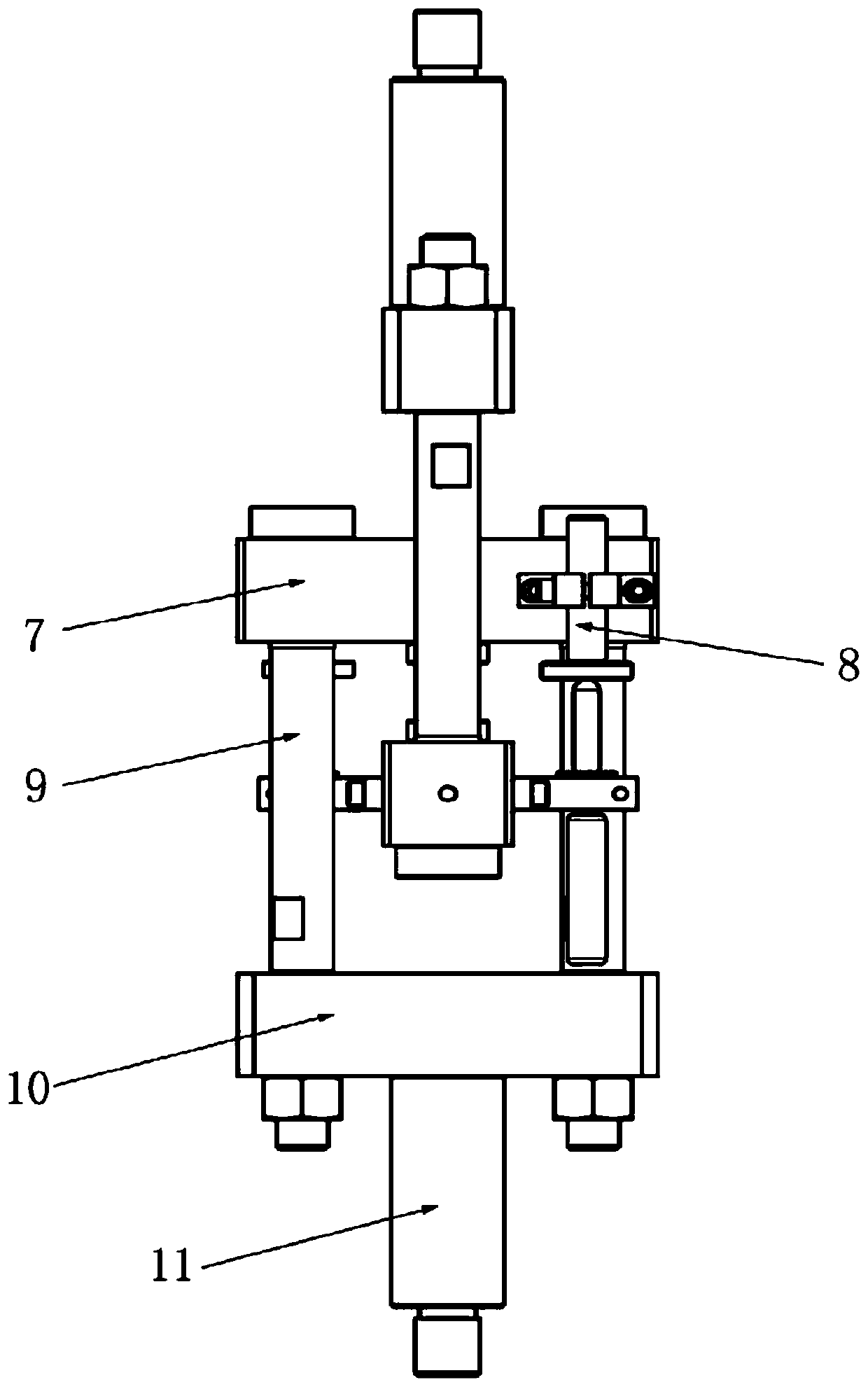

[0032] The present invention will be described in detail below with reference to the accompanying drawings.

[0033] like Figure 1-3 As shown in the figure, the present invention is a device that can use the existing tensile creep testing machine to carry out the compression creep test. The reverse fixture and deformation measuring device for compressive stress use grating to measure deformation, and the deformation resolution is 1μm.

[0034] The test device of the present invention includes an upper fixture, a lower fixture, a boss 12 and a grating sensor 5, and the structures and connection relationships of each part are as follows:

[0035] The upper fixture includes an upper plate I2, a lower bottom plate I, a column I3 and an upper stretching rod 1; the upper plate I and the lower bottom plate I are arranged in parallel, the column I is two, and the column I is vertically arranged on the upper plate I. and the lower bottom plate I and the upper plate I and the lower b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com