Diesel engine with base provided with a shock absorber and installation method of diesel engine

An installation method and shock absorber technology, applied in the direction of spring/shock absorber, machine/engine, supporting machine, etc., can solve the problems of inflexible installation, large volume and heavy weight, etc., to reduce labor intensity and improve seismic performance , the effect of high power output efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

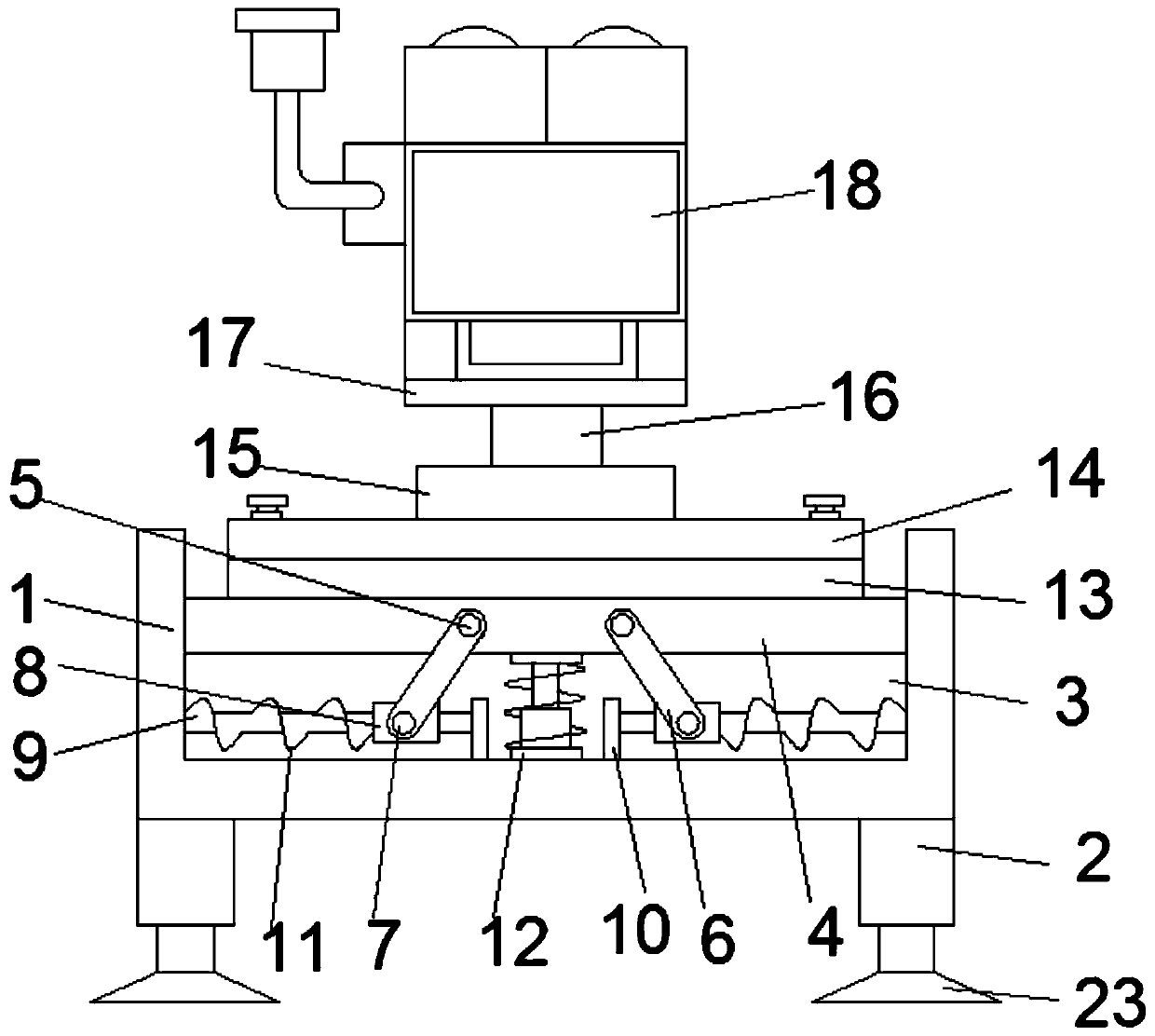

[0036] Such as Figure 1-3 As shown, a diesel engine with a base provided with a shock absorber according to an embodiment of the present invention includes a mounting base 1, the bottom of the mounting base 1 is symmetrically provided with shock absorbing columns 2, and the top of the mounting base 1 is provided with a shock absorbing groove. 3. A base 4 is provided in the damping groove 3, and a movable shaft-5 is symmetrically arranged on the base 4, and a support rod 6 is movably connected on the movable shaft-5, and the support rod 6 One end away from the movable shaft one 5 is sleeved on the movable shaft two 7, and the movable shaft two 7 is fixed on the slide block 8, and the slide block 8 is sleeved on the outside of the slide bar 9, and one end of the slide bar 9 is connected to the slide bar 9. The inner wall of the damping groove 3 is fixedly connected, and the other end of the sliding rod 9 is fixedly connected with the baffle plate 10. A shock absorbing spring 1...

Embodiment 2

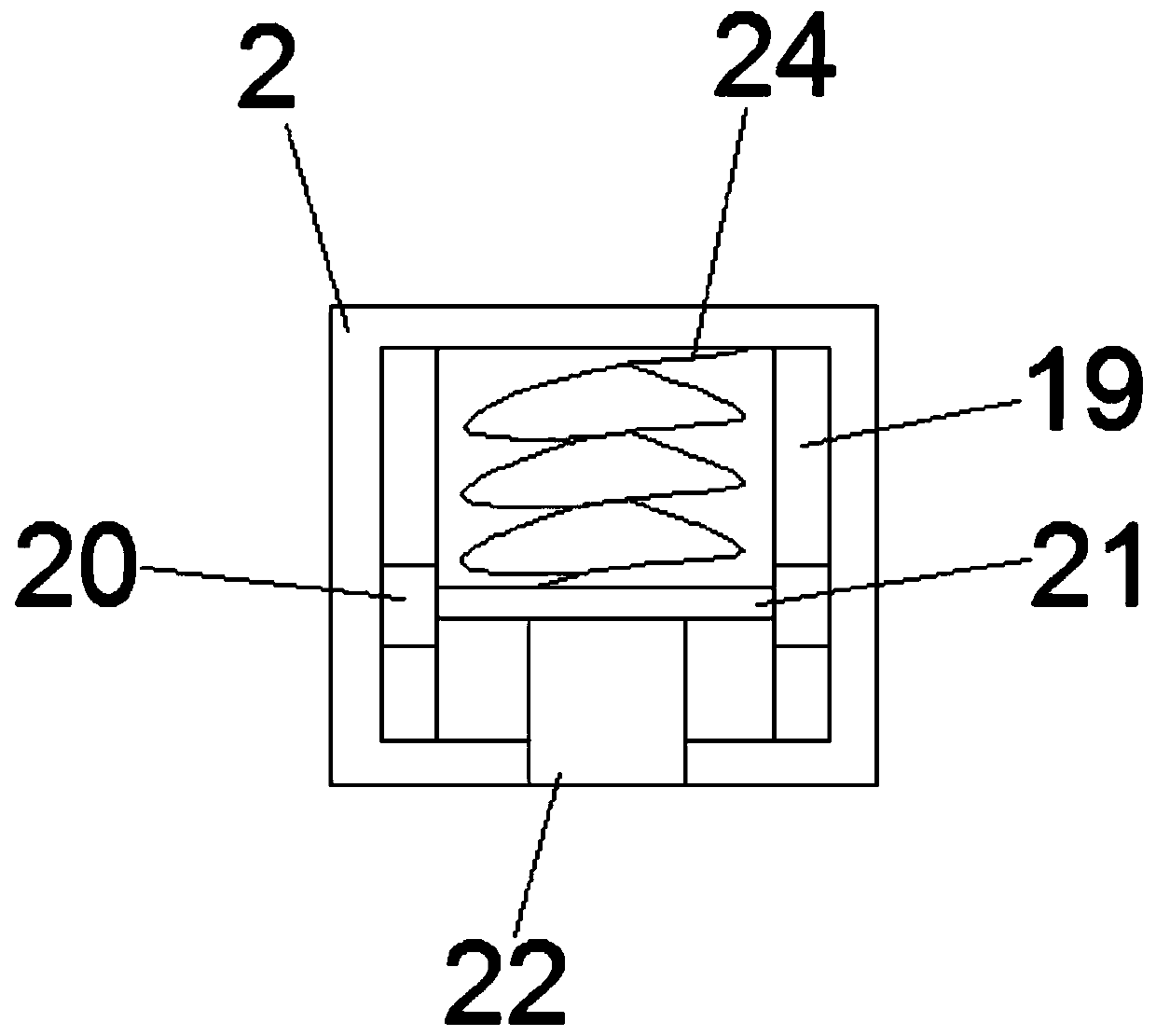

[0038] see Figure 1-3 , for the shock-absorbing column 2, the interior of the shock-absorbing column 2 is provided with a cavity, and the inside of the cavity is symmetrically provided with a limit groove 19, and the limit groove 19 is provided with a matching limit block 20 A limiting plate 21 is fixed between the limiting blocks 20 , and a supporting leg 22 is arranged at the bottom of the limiting plate 21 . As for the supporting leg 22 , the end of the supporting leg 22 away from the limiting plate 21 penetrates through the cavity and extends to the outside of the shock-absorbing column 2 to be provided with a non-slip pad 23 . For the limiting plate 21, a shock absorbing spring 2 24 is provided between the limiting plate 21 and the top of the cavity. With the cooperation of the bit plate 21 and the supporting legs 22, the anti-seismic performance of the mounting seat 1 is greatly improved.

Embodiment 3

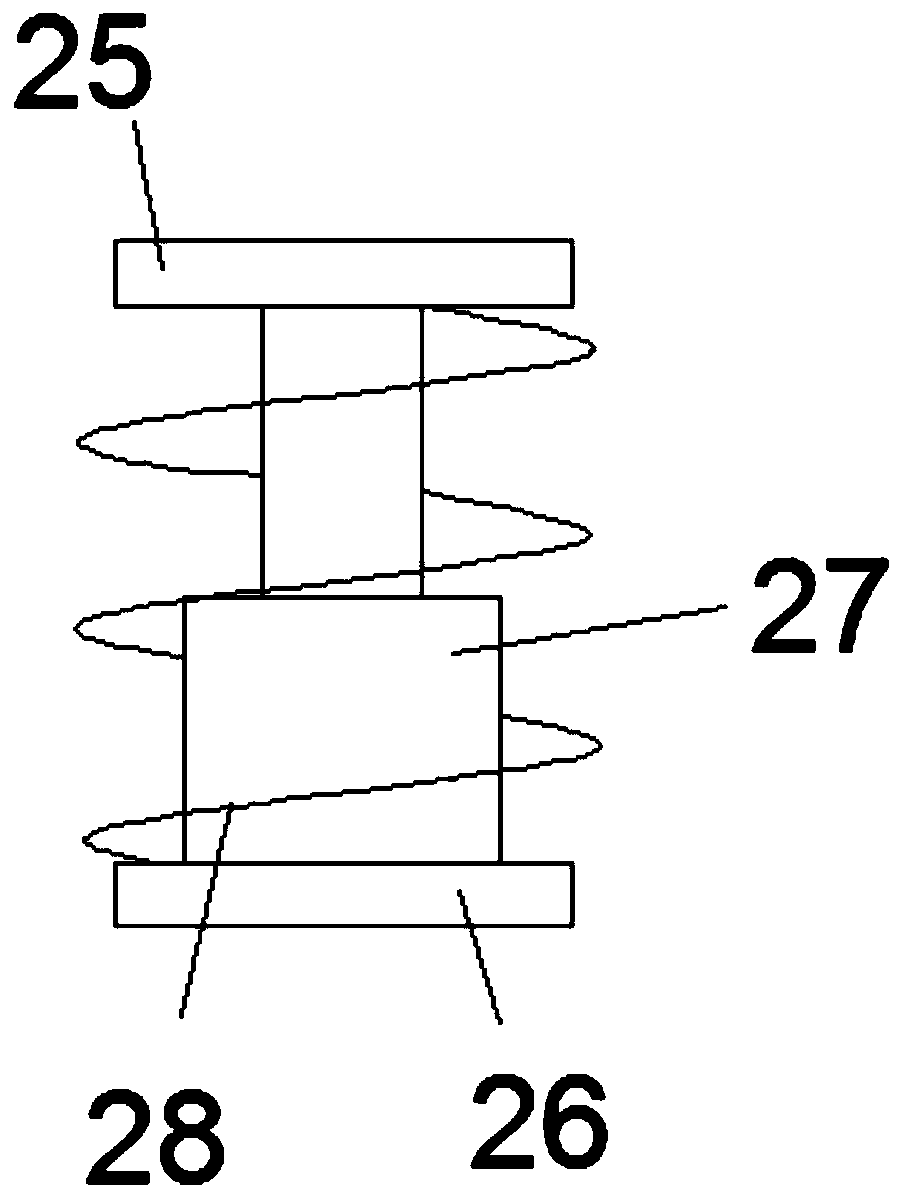

[0040] see Figure 1-3 , for the shock absorbing mechanism 12, the shock absorbing mechanism 12 includes an upper fixing plate 25 and a lower fixing plate 26, the upper fixing plate 25 is fixed on the bottom of the base 4, and the lower fixing plate 26 is fixed on the The bottom of the damping groove 3. For the upper fixed plate 25, a telescopic rod 27 is arranged between the upper fixed plate 25 and the lower fixed plate 26, and the telescopic rod 27 is located outside the upper fixed plate 25 and the lower fixed plate 26. The three shock absorbing springs 28 are set therebetween, and the shock absorbing springs two 24 further play a shock absorbing effect by being provided with the shock absorbing mechanism 12, so that the diesel engine 18 works more stably, thereby delaying the service life of the diesel engine 18 .

[0041] Such as Figure 1-4 As shown, according to another aspect of the present invention, a method for installing a diesel engine with a shock absorber on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com