Bulldozer gear-shifting controller and system

A technology for controllers and bulldozers, applied in the direction of transmission control, clutches, mechanical equipment, etc., can solve problems that affect the comfort of driving bulldozers, large shift shocks and pressure fluctuations, and reduce the service life of gearboxes in the transmission system. Achieve the effects of reducing shifting impact, improving overall life, and improving comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

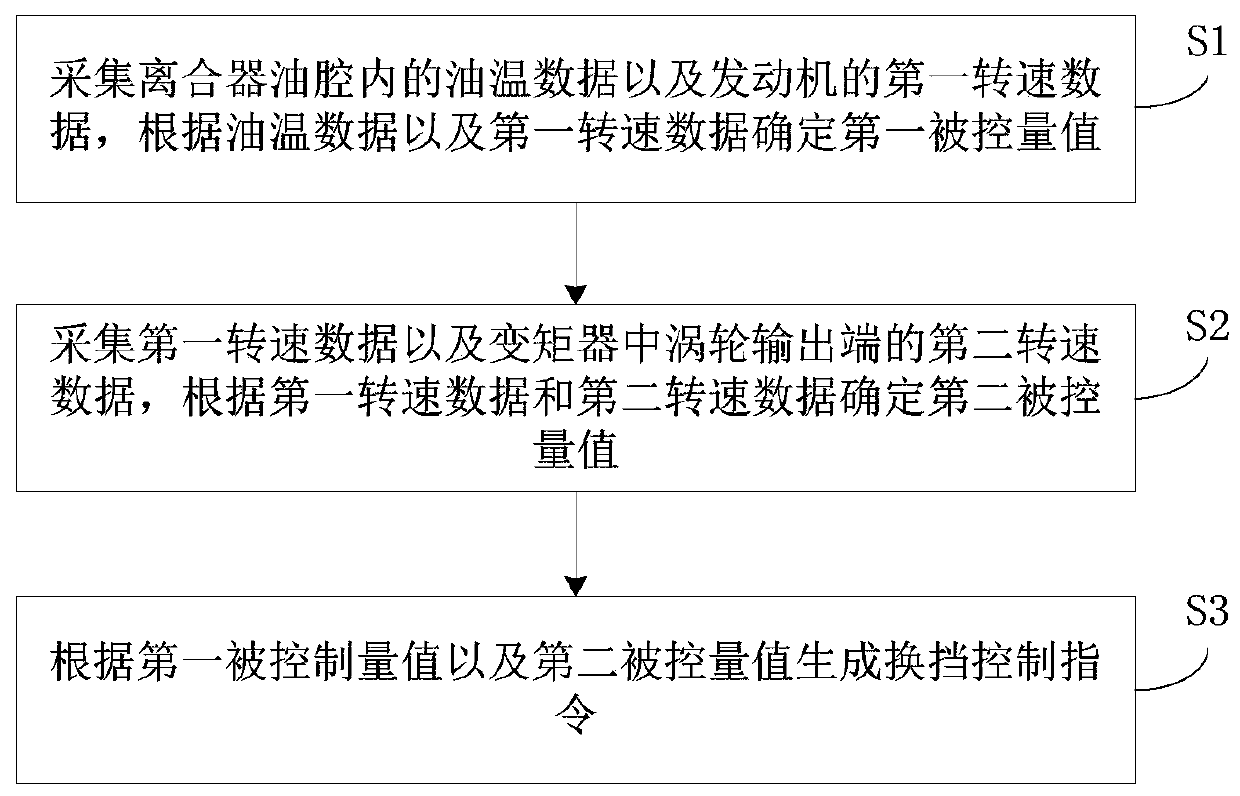

[0024] This embodiment proposes a bulldozer shift controller, figure 1 It is a kind of controller shift control flowchart in embodiment one, refer to figure 1 , shift control includes:

[0025] S1. Collect the oil temperature data in the clutch oil chamber and the first rotational speed data of the engine, and determine the first controlled value according to the oil temperature data and the first rotational speed data.

[0026] In this embodiment, the controller is used to generate a control command for the proportional solenoid valve disposed on the clutch, and the first controlled value is a target current value for controlling the proportional solenoid valve.

[0027] In the transmission system, the influencing factors related to the shifting quality include the transmission input speed, output speed, clutch oil chamber oil temperature, viscosity, pressure, clutch torque, torque converter pump pressure, transmission oil inlet pressure, etc. . In this embodiment, in orde...

Embodiment 2

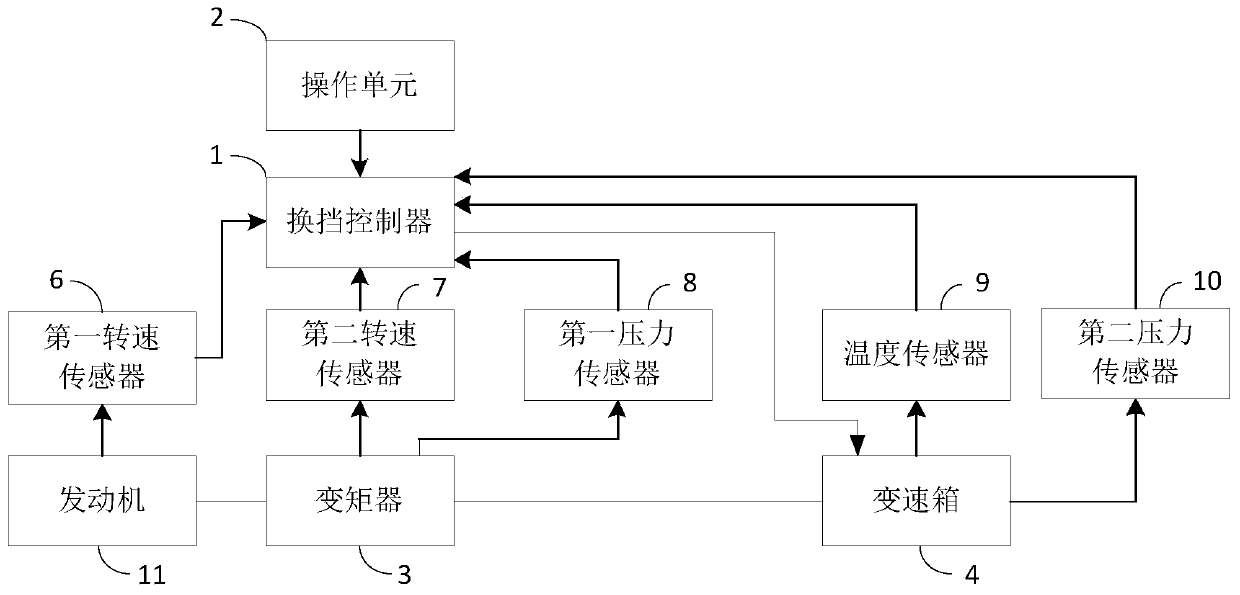

[0044] This embodiment proposes a bulldozer shift system, figure 2 It is the structural block diagram of the control system in the second embodiment, refer to figure 2 , the shift system includes a shift controller 1 , a shift operation unit 2 , a torque converter 3 , a gearbox 4 , a temperature sensor 9 , a first rotational speed sensor 6 and a second rotational speed sensor 7 . Wherein, the gearbox 4 is equipped with a proportional solenoid valve, and the proportional solenoid valve is used to adjust the flow of hydraulic oil entering the clutch according to the shift control instruction.

[0045] The shift controller 1 is used to generate a shift control instruction for controlling the gearbox 4 according to the first controlled quantity and the second controlled quantity. The shift operation unit 2 is electrically connected with the shift controller 1 for sending a shift request instruction, and the engine 11 is connected with the gearbox 4 through the torque converter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com