A high fluidity and high density intermediate level radioactive waste liquid cement solidification material and its solidification method

A radioactive waste liquid, high fluidity technology, used in radioactive purification, nuclear engineering, etc., can solve the problems of low fluidity, many pores, and bleeding in the solidified body, and achieve improved fluidity, excellent performance, and anti-aging properties. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The high-fluidity, high-density medium-level radioactive waste cement solidification material of this embodiment includes: P.O52.5 cement, medium-level radioactive waste, CGM-A and fatty alcohol sulfonate air-entraining agent; wherein, medium The mass ratio of horizontal radioactive waste liquid, Portland cement, CGM-A and air-entraining agent is 1000:2000:10:1; the salt content of intermediate level radioactive waste liquid is 120g / L.

[0024] The solidification method of the high-fluidity and high-density medium-level radioactive waste liquid cement solidification material of this embodiment comprises the following steps:

[0025] (1) Stir and mix the above-mentioned medium-level radioactive waste liquid, CGM-A and air-entraining agent uniformly, and then add them into Portland cement and stir and mix uniformly to prepare cement mortar.

[0026] (2) Pour the cement mortar into the test mold and cure it for 28 days.

[0027] The above-mentioned cured slurry has a comp...

Embodiment 2

[0029] The high-fluidity, high-density medium-level radioactive waste liquid cement solidification material of this embodiment includes: P.O42.5 cement, medium-level radioactive waste liquid, CGM-A and fatty alcohol sulfonate air-entraining agent; wherein, medium The mass ratio of horizontal radioactive waste liquid, Portland cement, CGM-A and air-entraining agent is 1000:2200:25:3; the salt content of intermediate level radioactive waste liquid is 180g / L.

[0030] The solidification method of the high-fluidity and high-density medium-level radioactive waste liquid cement solidification material of this embodiment comprises the following steps:

[0031] (1) Stir and mix the above-mentioned medium-level radioactive waste liquid, CGM-A and air-entraining agent uniformly, and then add them into Portland cement and stir and mix uniformly to prepare cement mortar.

[0032] (2) Pour the cement mortar into the test mold and cure it for 28 days.

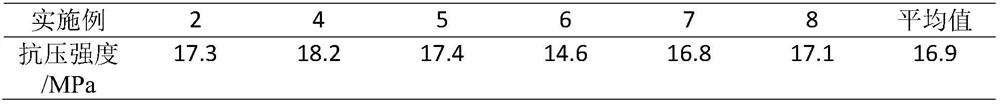

[0033] The above-mentioned cured slu...

Embodiment 3

[0035] The high-fluidity, high-density medium-level radioactive waste cement solidification material of this embodiment includes: P.O52.5 cement, medium-level radioactive waste, CGM-A and fatty alcohol sulfonate air-entraining agent; wherein, medium The mass ratio of horizontal radioactive waste liquid, Portland cement, CGM-A and air-entraining agent is 1000:2500:50:5; the salt content of medium level radioactive waste liquid is 240g / L.

[0036] The solidification method of the high-fluidity and high-density medium-level radioactive waste liquid cement solidification material of this embodiment comprises the following steps:

[0037] (1) Stir and mix the above-mentioned medium-level radioactive waste liquid, CGM-A and air-entraining agent uniformly, and then add them into Portland cement and stir and mix uniformly to prepare cement mortar.

[0038] (2) Pour the cement mortar into the trial mold and cure for 30 days.

[0039] The above-mentioned cured slurry has a compressive ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com