Fuel supply device for cryogenic fuels, and method for operating a fuel supply device for cryogenic fuels

A low-temperature fuel and fuel delivery technology, which is applied to pump devices, oil supply devices, charging systems, etc., can solve the problems of large size of the pre-delivery pump and the influence of the efficiency of the fuel delivery device, and achieve the effect of reducing the installation space requirement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

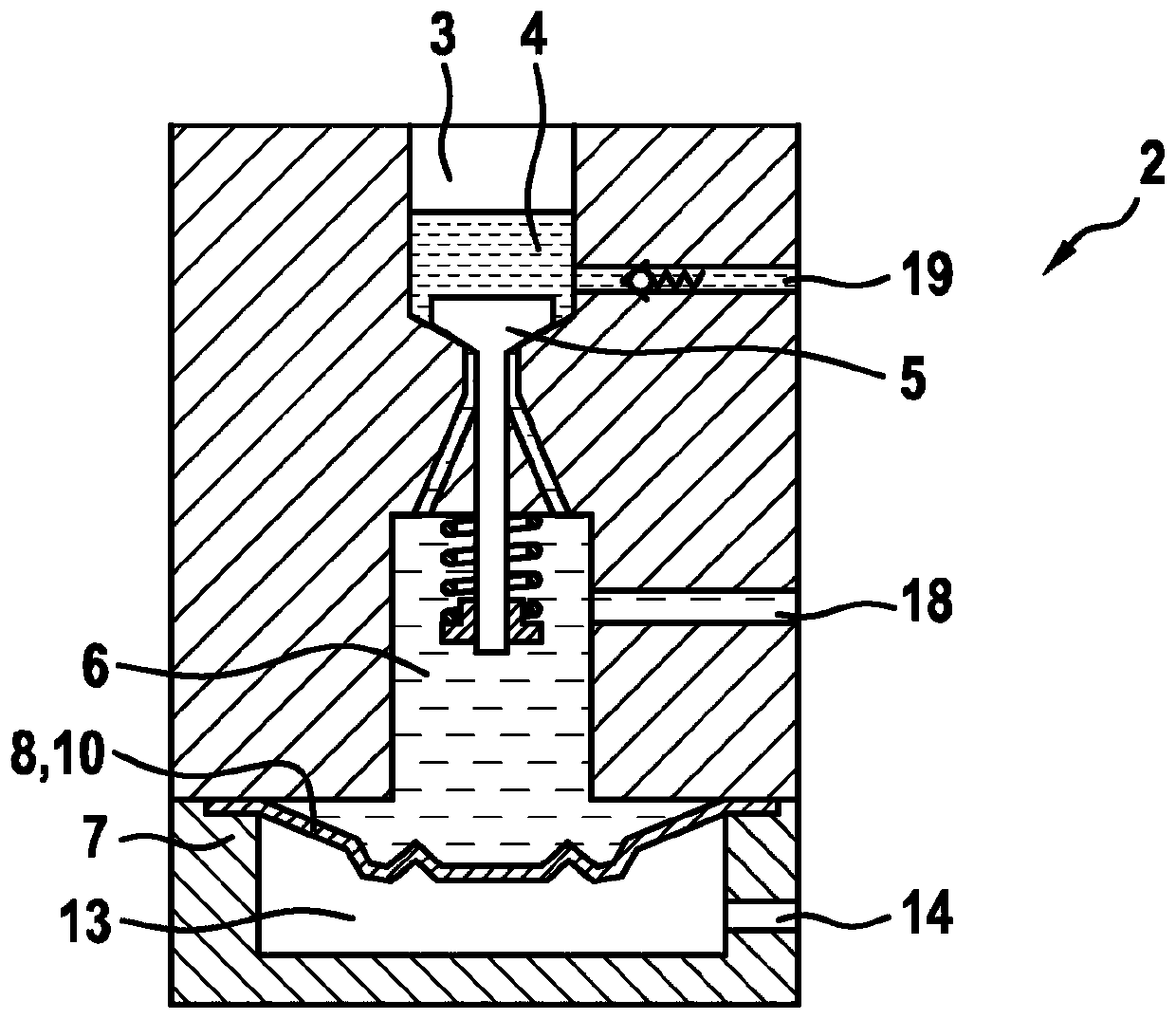

[0024] exist figure 1 The fuel delivery device according to the invention shown in , comprises a pre-feed pump 1 and a high-pressure pump 2 , wherein the pre-feed pump 1 is currently arranged in the bottom region of a tank 15 for storing cryogenic fuel. A liquid phase 16 of the fuel is present there, which is covered by a gaseous phase 17 of the fuel. The arrangement of the pre-feed pump 1 in the tank 15 has the advantage that the structural outlay for connecting the pre-feed pump 1 to the high-pressure pump 2 is reduced since only the low-pressure line 18 needs to be led out of the tank 15 . The prefeed pump 1 can in particular be embodied as a side channel pump or a centrifugal pump.

[0025] The additionally provided high-pressure pump 2 is designed as a single-piston pump. The single-piston pump has a compression chamber 4 which is delimited by a reciprocating piston 3 and which can be filled with cryogenic fuel via a suction valve 5 . In this case, fuel is withdrawn fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com