Adjustable sealing structure of regulating valve

A sealing structure and adjustable technology, applied in the field of regulating valves, can solve the problems of external leakage or internal leakage, low production efficiency of regulating valves, etc., and achieve the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

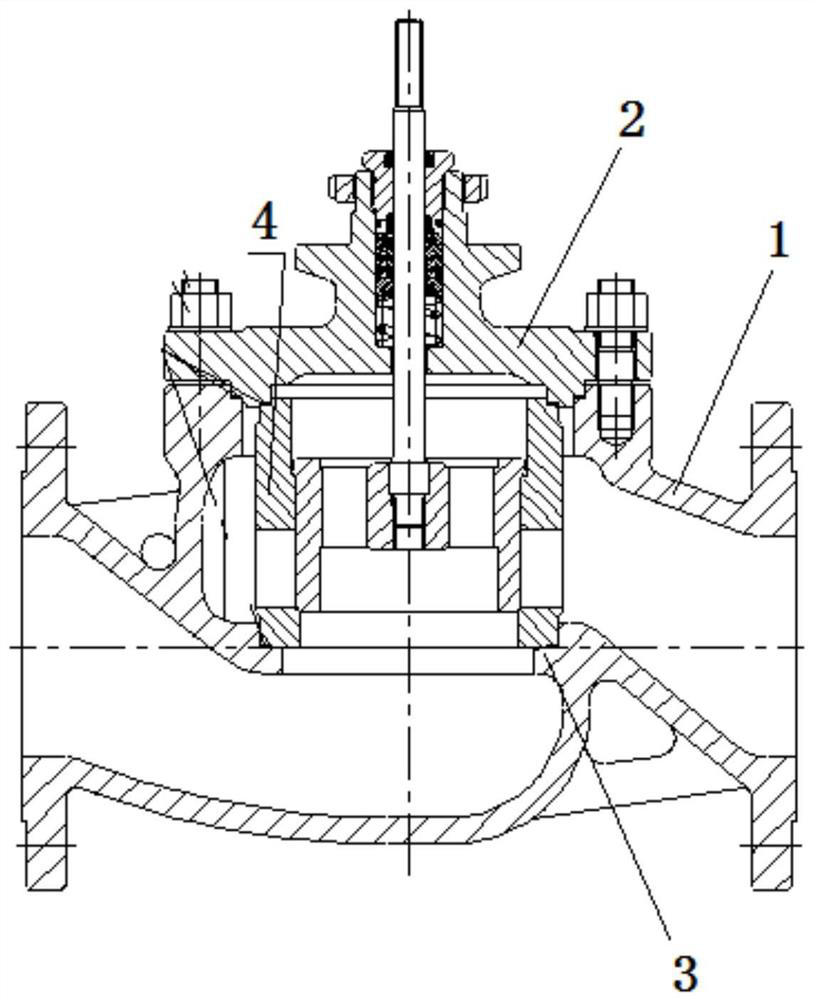

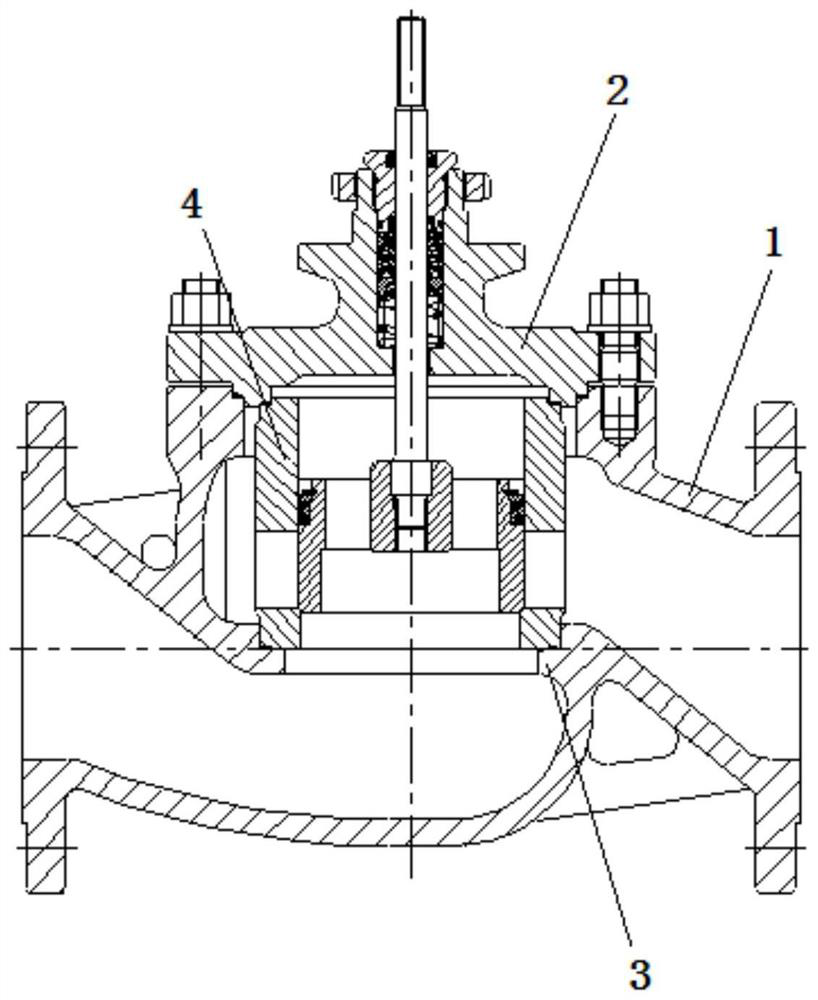

[0047] Specific embodiment one: as Figure 5 , Image 6 , Figure 7 As shown, an adjustable sealing structure of a regulating valve includes a valve body 1, a valve cover 2, a valve seat 3 located in the valve body, a cage 4 located in the valve body, and a sealing adjustment mechanism 5. A valve cover sealing gasket 7 is arranged between the valve body and the valve cover. In this embodiment, the valve body and the valve cover are connected by bolts, and the valve cover sealing gasket between the valve cover and the valve body is pressed by tightening the bolts connecting the valve cover and the valve body to achieve the valve cover and the valve body. The seal between the valve seats. A valve seat sealing gasket 6 is arranged between the lower end of the valve cage and the valve seat. The sealing adjustment mechanism 5 includes a top ring 5.0 located between the bonnet and the upper end of the cage, a threaded hole arranged on the bonnet, an adjusting screw 5.1 matched ...

specific Embodiment 2

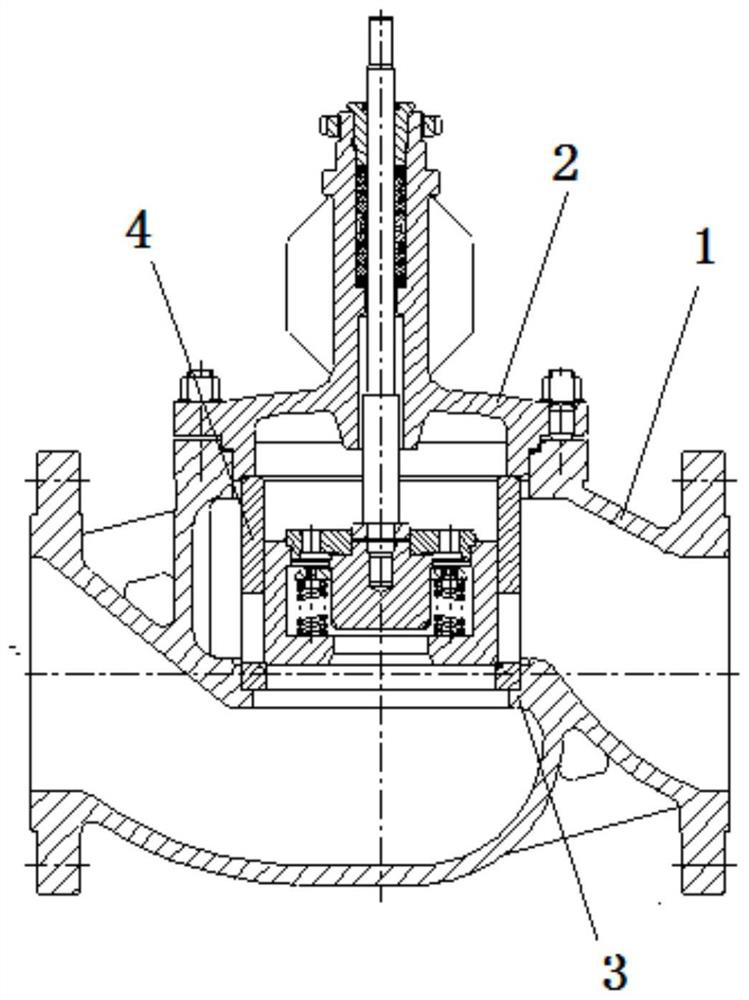

[0055] Specific embodiment two: the specific structure of this embodiment is with reference to specific embodiment one, and its difference is:

[0056] Such as Figure 8 As shown, the inner edge of the top ring 5.0 is provided with a blocking sleeve 5.5 extending downward, and the lower end of the blocking sleeve extends downward into the valve cage. The gap between the outer surface of the blocking sleeve and the inner surface of the cage is smaller than the set value. In this embodiment, the gap between the outer surface of the blocking sleeve and the inner surface of the cage is 0.1 mm or 0.2 mm or 0.3 mm. The blocking sleeve is used to block the gravel in the water from entering the preset gap.

[0057] Since there may be sand and stones in the water, during the use of the control valve, once the sand and stones in the water enter the preset gap, the axial deformation of the cage due to thermal expansion and contraction will not be effectively absorbed by the elastic elem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com