A Fault Detection Method for Dual Sensor Redundancy of Hydrotron Governor Servotron

A fault detection, dual-sensor technology, applied in the fields of hydropower, machinery/engine, mechanical equipment, etc., can solve the problem of unable to detect the fault of the displacement sensor, and achieve the effect of reminding eye-catching and timely, ensuring accuracy, and preventing misjudgment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

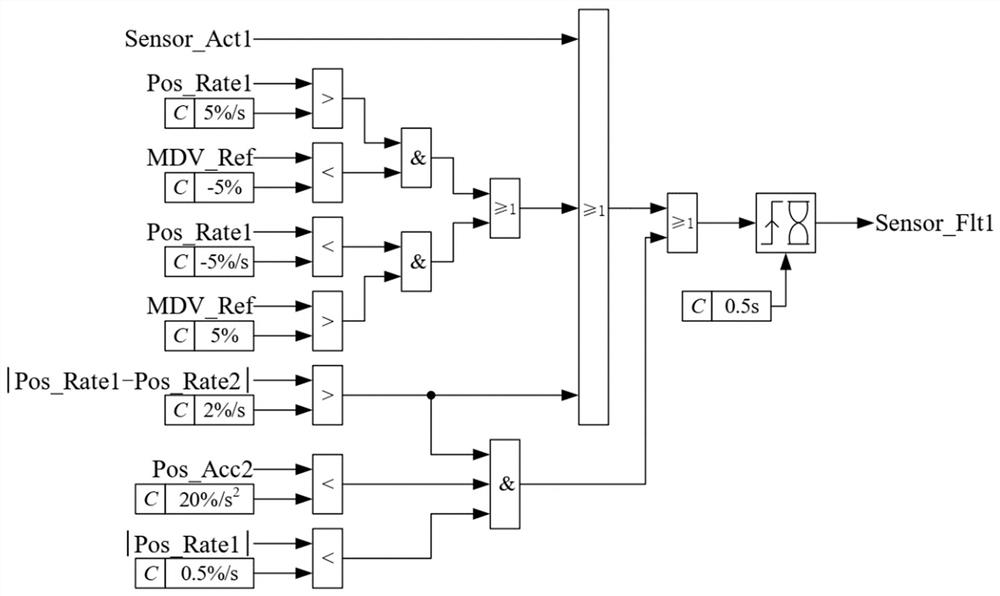

[0032] As the basic embodiment of the present invention, with reference to the description attached figure 1, the present invention includes a dual-sensor redundant fault detection method for a hydroturbine governor servomotor, and uses a displacement sensor one and a displacement sensor two redundant mode to perform fault detection on the servomotor displacement sensor, and the fault detection specifically includes the following step:

[0033] a. Use displacement sensor 1 to measure the actual position Pos of the servomotor 1 , using displacement sensor 2 to measure the actual position Pos of the servomotor 2 ;

[0034] b. Measured main valve position reference MDV_Ref;

[0035] c. During the program cycle, the actual position of the servomotor Pos 1 and Pos 2 Differentiate separately to get the servomotor displacement change rate Pos_Rate 1 and Pos_Rate 2 ;

[0036] d. Pos_Rate of servomotor displacement change rate 1 and Pos_Rate 2 Differentiate to get the servomo...

Embodiment 2

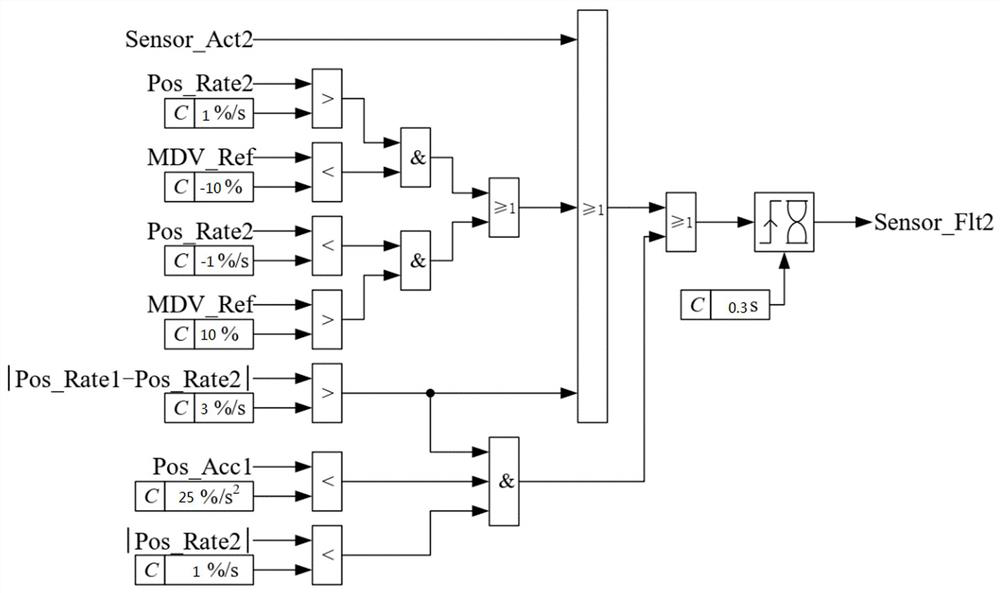

[0040] As a preferred embodiment of the present invention, with reference to the attached figure 2 , the present invention includes a double-sensor redundant fault detection method for a hydraulic turbine governor servomotor, compared with embodiment 1, the steps of the detection method are the same as steps a, b, c and d in embodiment 1, and different The lies in step e:

[0041] Carry out fault judgment on displacement sensor 1 and displacement sensor 2. When the connecting rod of the slider of the magnetostrictive displacement sensor breaks, if the displacement sensor 2 is mainly used at this time, when the Pos_Rate is measured in real time 2 10%, and also detected |Pos_Rate 1 -Pos_Rate 2 |>3% / s, after the above state is maintained for 0.3s, it is judged that the second displacement sensor is faulty.

[0042] If measured|Pos_Rate 2 |1 -Pos_Rate 2 |>3% / s, and detect Pos_Acc at the same time 1 2 , after the above state is maintained for 0.3s, it is judged that the sec...

Embodiment 3

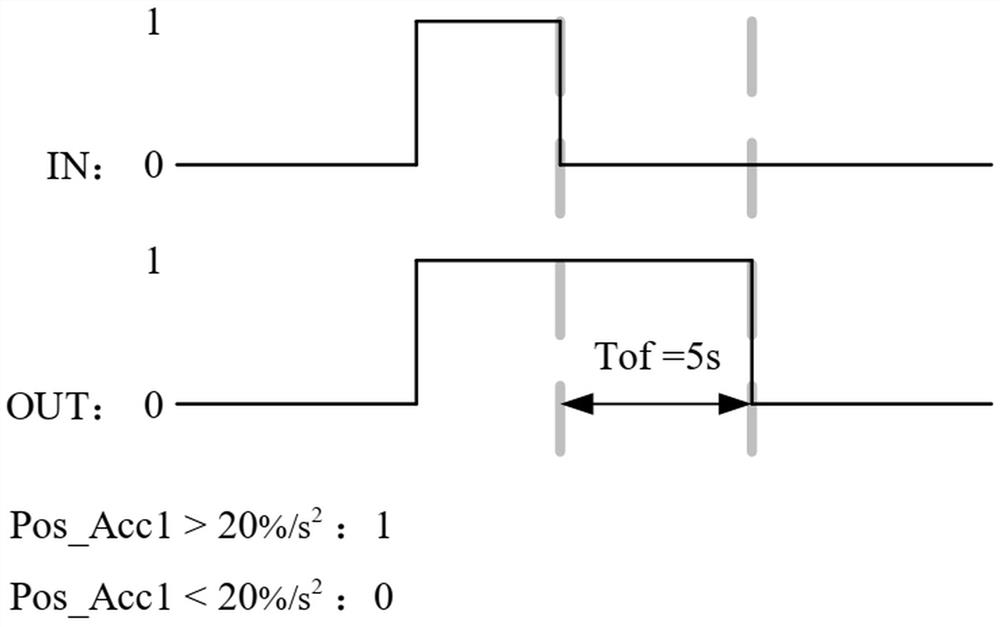

[0044] As the best implementation mode of the present invention, with reference to the attached figure 1 , manual attached figure 2 , manual attached image 3 with instructions attached Figure 4 , the present invention includes a dual-sensor redundant fault detection method for a hydraulic turbine governor servomotor. Fault detection can efficiently detect the fault of the displacement sensor when the connecting rod of the displacement sensor slider is broken or the cable is broken but the output signal is normal, and effectively prevents misjudgment of other fault types; the detection method includes the following steps :

[0045] a. Use displacement sensor 1 to measure the actual position Pos of the servomotor 1 , using displacement sensor 2 to measure the actual position Pos of the servomotor 2 ;

[0046] b. The main valve position reference MDV_Ref is measured, and the main valve position reference is the difference between the adjustment output and the displacemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com