Broken-bridge aluminum profile

A technology for broken bridge aluminum and profiles, applied in the field of broken bridge aluminum, can solve the problems of a large number of mold openings, high manufacturing cost, and long listing cycle for broken bridge aluminum doors and windows, and achieves convenient and fast modification, good applicability, and assembly difficulty. reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

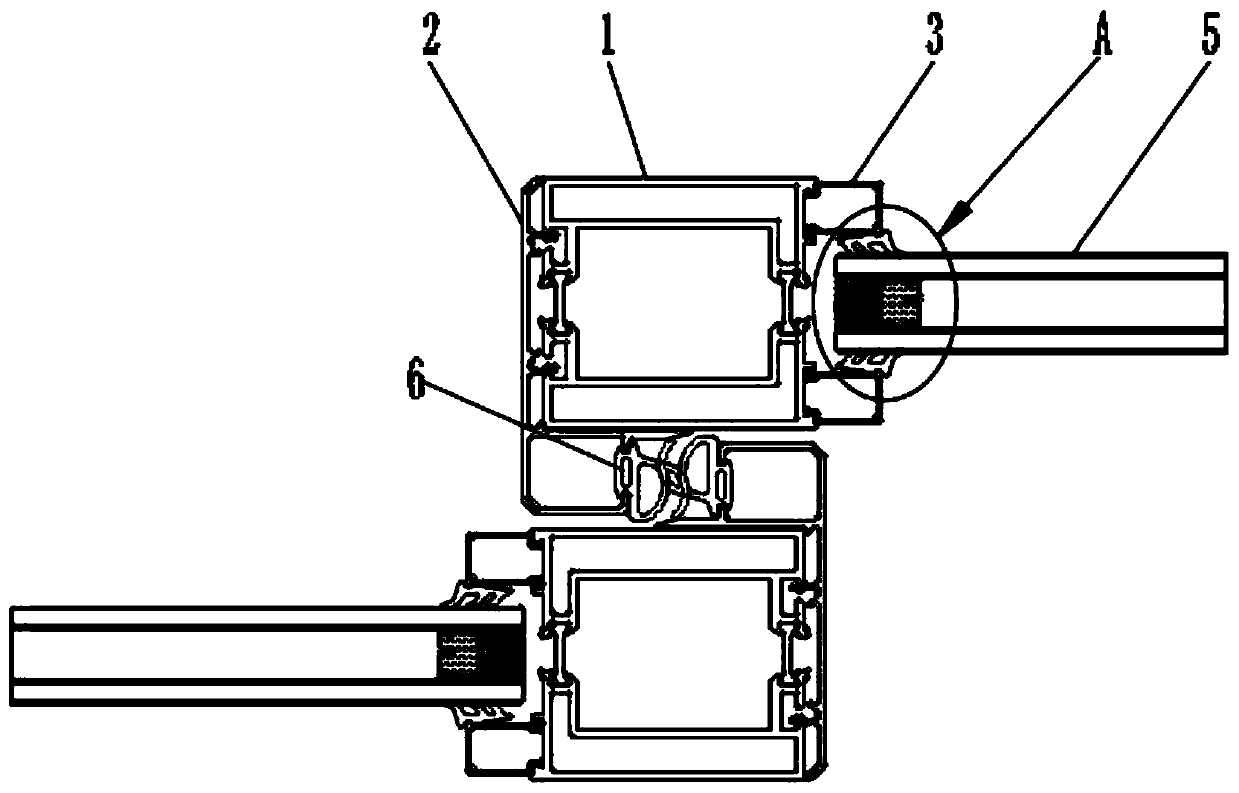

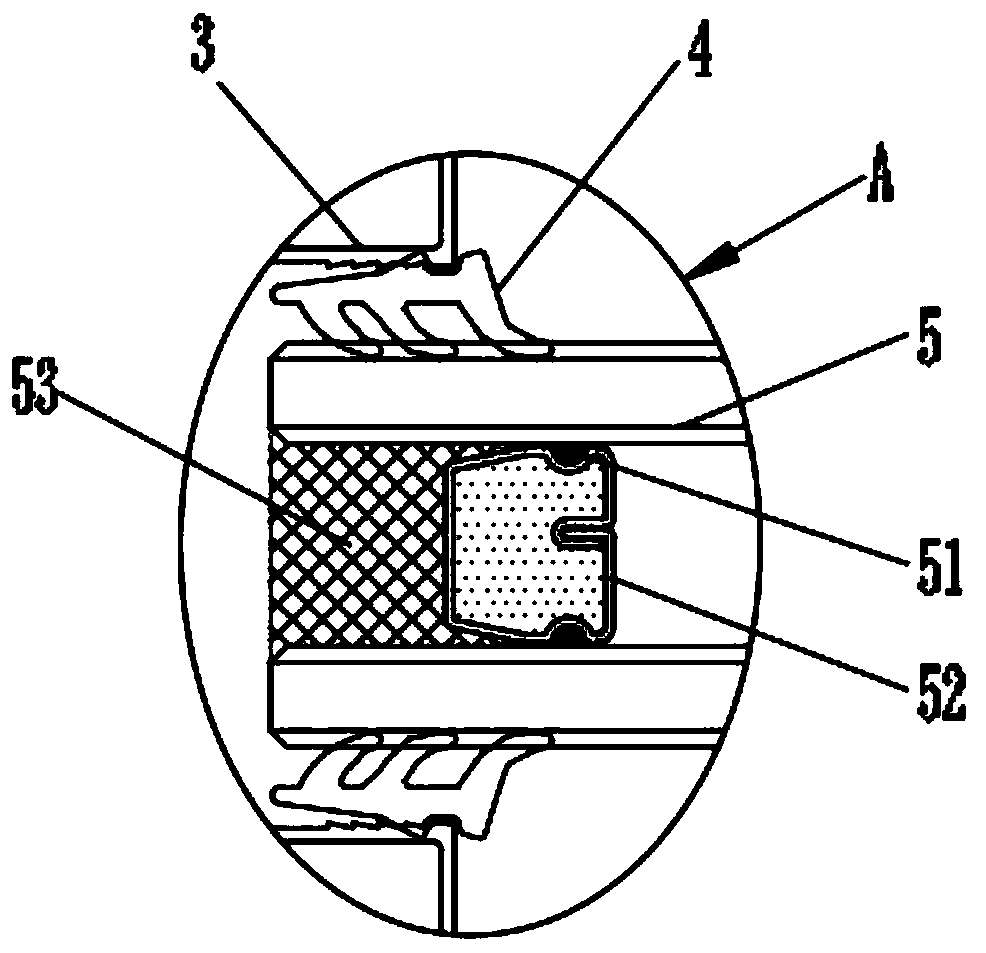

[0022] refer to Figure 1-2 , a broken bridge aluminum profile, including broken bridge aluminum 1, the left end of the broken bridge aluminum 1 is fixedly installed with a variable end face connector 2, the right end of the broken bridge aluminum 1 is fixedly installed with a variable bead 3, and the variable bead 3 The inner side of the inner side is fixedly installed with a tightening rubber strip 4, and the inside of the tightening rubber strip 4 is fixedly equipped with a hollow glass 5.

[0023] In this embodiment, a sealing strip 51 is arranged inside the insulating glass 5 , a supporting shell 52 is installed inside the insulating glass 5 , and a sealant 53 is filled in the insulating glass 5 . Through the design of the sealing strip 51 , the supporting shell 52 and the sealant 53 , the insulating glass 5 can be fixed.

[0024] In this embodiment, the number of variable bezels 3 installed on the side of each broken bridge aluminum 1 is two, and the two variable beaded...

Embodiment 2

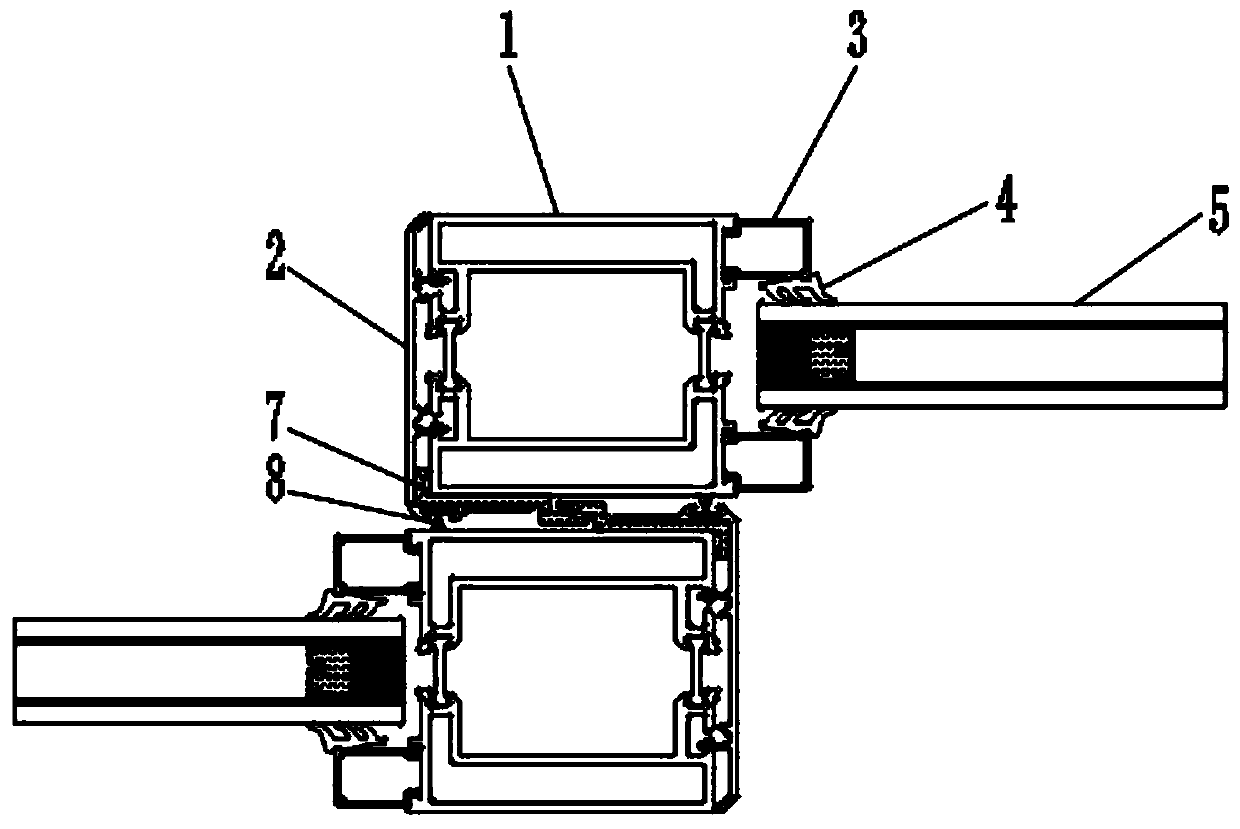

[0028] refer to figure 2 , image 3 , a broken bridge aluminum profile, including broken bridge aluminum 1, the left end of the broken bridge aluminum 1 is fixedly installed with a variable end face connector 2, the right end of the broken bridge aluminum 1 is fixedly installed with a variable bead 3, and the variable bead 3 The inner side of the inner side is fixedly installed with a tightening rubber strip 4, and the inside of the tightening rubber strip 4 is fixedly equipped with a hollow glass 5.

[0029] In this embodiment, a sealing strip 51 is arranged inside the insulating glass 5 , a supporting shell 52 is installed inside the insulating glass 5 , and a sealant 53 is filled in the insulating glass 5 . Through the design of the sealing strip 51 , the supporting shell 52 and the sealant 53 , the insulating glass 5 can be fixed.

[0030] In this embodiment, the number of variable bezels 3 installed on the side of each broken bridge aluminum 1 is two, and the two varia...

Embodiment 3

[0034] refer to figure 2 , Figure 4 , a broken bridge aluminum profile, including broken bridge aluminum 1, the left end of the broken bridge aluminum 1 is fixedly installed with a variable end face connector 2, the right end of the broken bridge aluminum 1 is fixedly installed with a variable bead 3, and the variable bead 3 The inner side of the inner side is fixedly installed with a tightening rubber strip 4, and the inside of the tightening rubber strip 4 is fixedly equipped with a hollow glass 5.

[0035] In this embodiment, a sealing strip 51 is arranged inside the insulating glass 5 , a supporting shell 52 is installed inside the insulating glass 5 , and a sealant 53 is filled in the insulating glass 5 . Through the design of the sealing strip 51 , the supporting shell 52 and the sealant 53 , the insulating glass 5 can be fixed.

[0036] In this embodiment, the number of variable bezels 3 installed on the side of each broken bridge aluminum 1 is two, and the two vari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com