Multi-hole punching die

A porous stamping and mold technology, applied in the field of porous stamping molds, can solve problems such as different stamping position support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

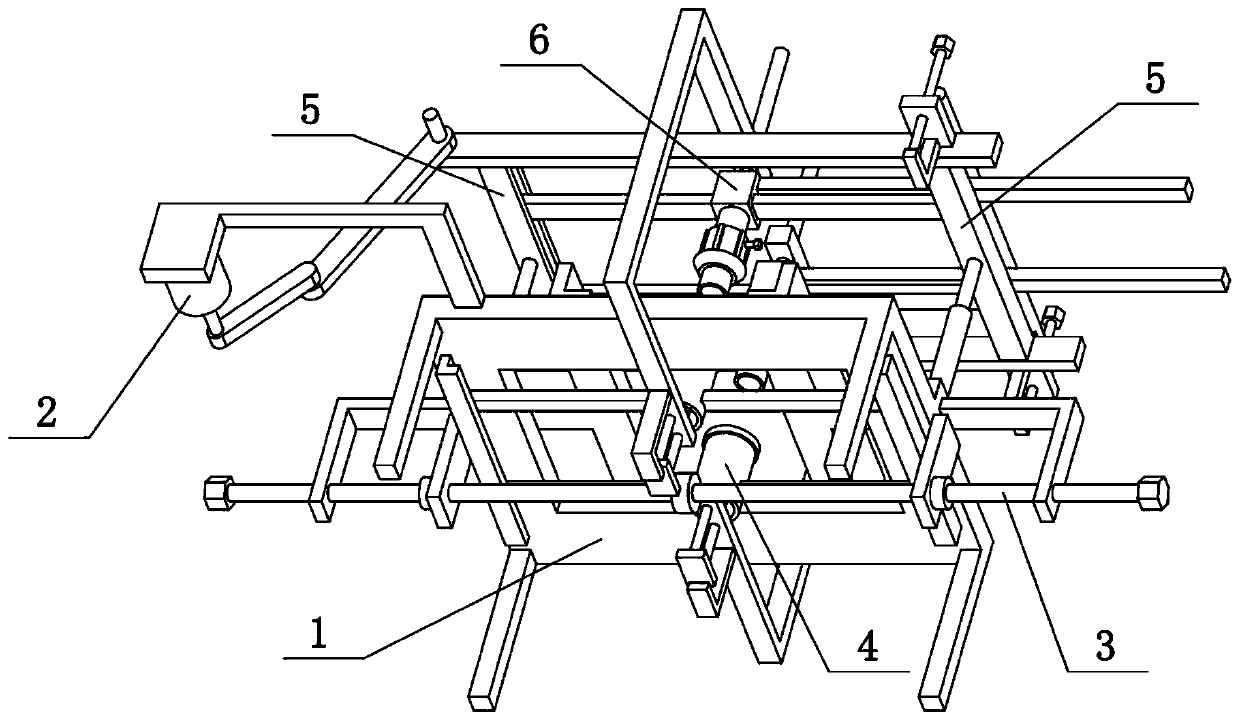

[0028] Combine below Figure 1-9 To illustrate the present embodiment, the present invention relates to a die, more specifically a porous stamping die, comprising a flat plate 1, support legs 103, rectangular holes 105, L-shaped bars 107, cylinder 4, transverse columns 401 and rubber rings 402. In the present invention, the two cylinders 4 can support the stamping position during stamping, and the positions of the two cylinders 4 can be adjusted to facilitate stamping at different positions.

[0029] The four corners of the lower side of the flat panel 1 are fixedly connected with supporting legs 103, the flat panel 1 is provided with a rectangular hole 105, and the left and right ends of the lower side of the flat panel 1 are fixedly connected with L-shaped bars 107, and the two L-shaped bars 107 are slidably connected with two transverse columns 401 in the front and rear directions, and the two cylinders 4 are respectively slidably connected on the two transverse columns 401...

specific Embodiment approach 2

[0031] Combine below Figure 1-9To illustrate this embodiment, the porous stamping die also includes a fixed sleeve 102, a protruding piece 106, a bidirectional threaded screw 3, a limit ring 301, a threaded hole piece 302, a horizontal slide bar 303 and a clamp seat 305, and the left and right sides of the flat plate 1 Both are fixedly connected with lugs 106, the left and right ends of the upper side of the plate 1 are fixedly connected with fixed sleeves 102, and the two horizontal slide bars 303 are respectively slidably connected to the two fixed sleeves 102, and the outer ends of the two horizontal slide bars 303 Both ends are fixedly connected with threaded holes 302, and the left and right ends of the two-way threaded screw 3 are rotatably connected to the two lugs 106 respectively. Fit the outer sides of the two lugs 106 respectively, the helical directions of the left and right ends of the two-way threaded screw 3 are opposite, and the left and right ends of the two-...

specific Embodiment approach 3

[0033] Combine below Figure 1-9 To illustrate this embodiment, the porous stamping die also includes a cross rib 104 and a clamp rib 304, the outer sides of the two clamp seats 305 are fixedly connected with the clamp rib 304, the front and rear ends of the flat plate 1 are provided with the cross rib 104, two The holders 305 are slidably connected to the two transverse edges 104 in the left-right direction. When the two clamping seats 305 approach, the two clamping ribs 304 also approach, and then the metal plate to be stamped is clamped and fixed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com