Treatment device for pollution gas generated by coke oven

A polluting gas and coke oven technology, which is applied in the field of polluting gas treatment devices produced by coke ovens, can solve problems such as environmental pollution, smoke and dust collection rate cannot reach 100%, and smoke and dust escape, so as to improve the environment and working conditions, and daily operation Low cost, effect of improving air quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

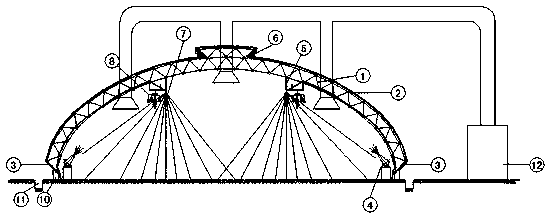

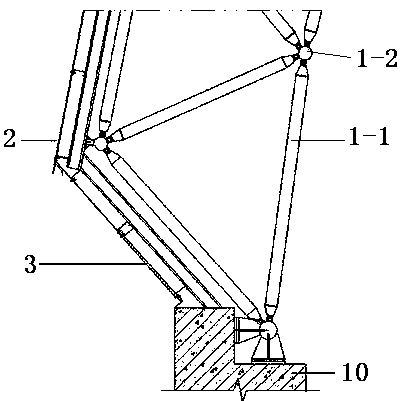

[0038] figure 1 , figure 2 , image 3 As shown, a pollution gas treatment device produced by a coke oven consists of a foundation 10, a closed warehouse 1, an overhaul road 5, a roof system 2, a ventilation system, a gas purification system 12, a spray dust removal system 4, a fire protection system, a monitoring system, and lighting System 7 and drainage system 11 form.

[0039] The enclosure 1 is attached to a foundation 10 .

[0040] Coke ovens, coal delivery trestles, coke pushers, coal presses and other operating equipment that are prone to dust and polluting gases are covered in the closed warehouse 1.

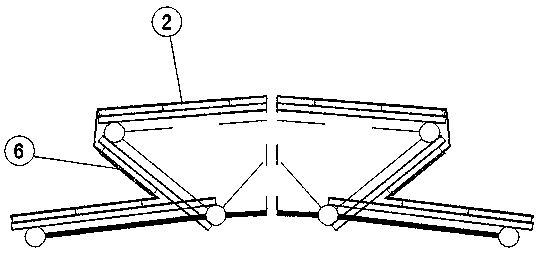

[0041] The roof system 2 is installed on the outer surface of the closed warehouse 1; the ventilation system is installed at the bottom and top of the closed warehouse; the gas purification system 12 is installed in the closed warehouse 1, and the gas collection ports are distributed inside the closed warehouse; the maintenance track 5 is installed on the top of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com