new style 2 Coated mesoporous hollow carbon sphere composite material and its preparation method and application in supercapacitor

A technology for supercapacitors and hollow carbon spheres, applied in hybrid capacitor electrodes, binary selenium/tellurium compounds, nano-carbons, etc., can solve the problems of harsh preparation conditions, complicated procedures, and high equipment requirements, and achieve simple preparation processes and simple methods Ease of operation and high safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

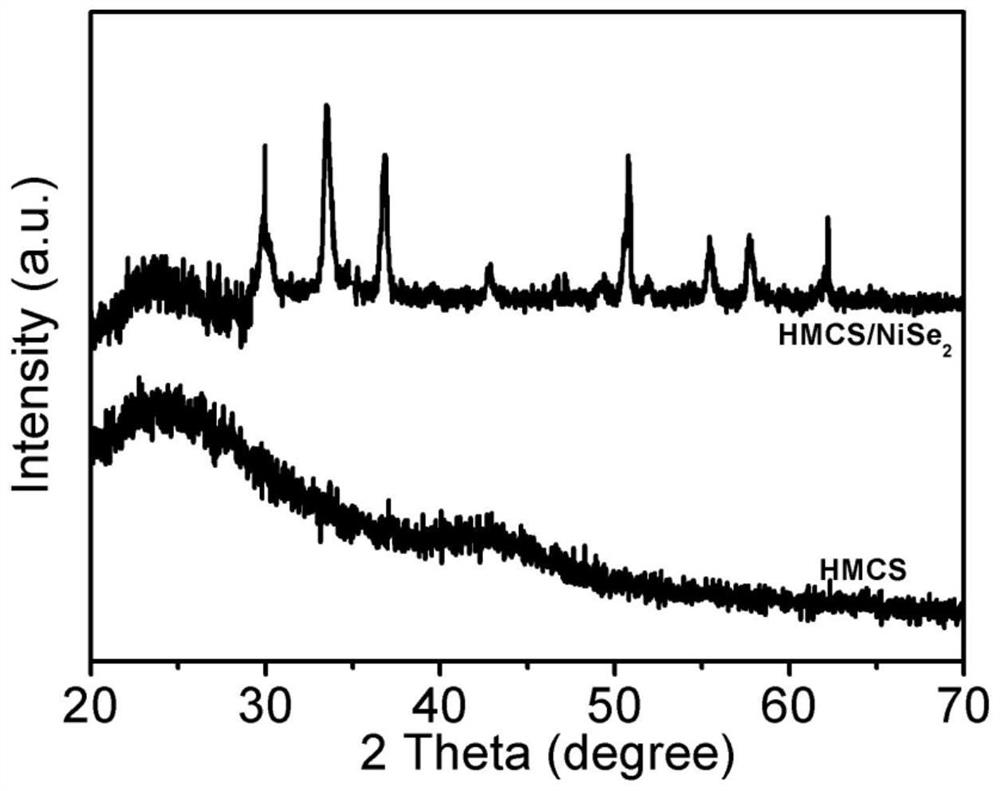

[0062] A kind of novel NiSe of the present embodiment 2 A method for preparing a coated mesoporous hollow carbon sphere composite material, the method specifically includes the following steps:

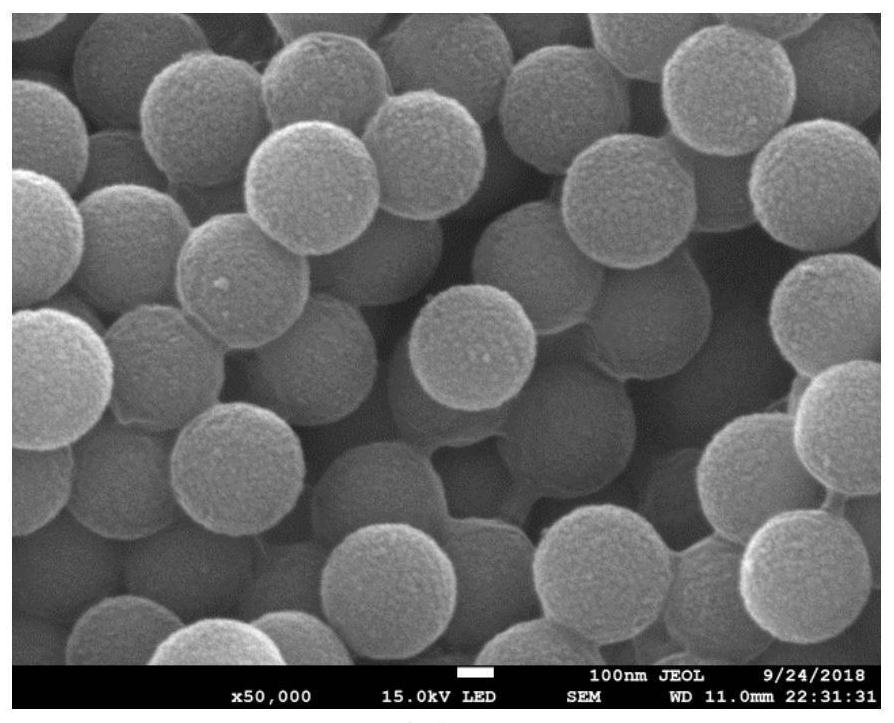

[0063] (1) Preparation of mesoporous hollow carbon spheres

[0064] (i) Use propyl orthosilicate (TPOS) and orthoethyl orthosilicate (TEOS) as the silicon source to ultrasonically disperse in an aqueous solution dissolved in ethanol (solvent) and ammonia (basic condition) for 10 minutes, then add m-phthalic acid Phenol (used to provide phenolic hydroxyl groups) and formaldehyde (used to provide aldehyde hydroxyl groups), and then the resulting mixture was magnetically stirred at room temperature for 20h, and finally suction filtered, washed, and dried to obtain SiO 2 / SiO 2 @RF Composite structure. The consumption of wherein said TPOS, TEOS is respectively 0.5mmol, 1.5mmol; The consumption of ethanol, ammoniacal liquor, deionized water is 60ml, 3ml, 20ml successively, and the consu...

Embodiment 2

[0081] A kind of novel NiSe of the present embodiment 2 A method for preparing a coated mesoporous hollow carbon sphere composite material, the method specifically includes the following steps:

[0082] (1) Preparation of mesoporous hollow carbon spheres

[0083] (i) ultrasonically disperse methyl orthosilicate (TMOS) as a silicon source in an aqueous solution of ethanol (solvent) and ammonia (basic condition) for 15 min, then add resorcinol (for providing phenolic hydroxyl groups) and Formaldehyde (used to provide aldehyde hydroxyl groups), and then the resulting mixture was magnetically stirred at room temperature for 25h, and finally suction filtered, washed, and dried to obtain SiO 2 / SiO 2 @RF Composite structure. The consumption of wherein said TMOS is 2mmol; The consumption of ethanol, ammoniacal liquor, deionized water is successively 60ml, 3ml, 20ml, and the consumption of resorcinol is 0.3g, and the consumption of formaldehyde is 0.56ml (the density of described f...

Embodiment 3

[0092] A kind of novel NiSe of the present embodiment 2 A method for preparing a coated mesoporous hollow carbon sphere composite material, the method specifically includes the following steps:

[0093] (1) Preparation of mesoporous hollow carbon spheres

[0094] (i) Sodium silicate (Na 2 SiO 3 ) was ultrasonically dispersed as a silicon source in an aqueous solution dissolved with ethanol (solvent) and ammonia water (basic condition) for 20 min, then resorcinol (for providing phenolic hydroxyl) and formaldehyde (for providing aldehyde hydroxyl) were added, and then The resulting mixture was magnetically stirred at room temperature for 30 h, and finally filtered, washed, and dried to obtain SiO 2 / SiO 2 @RF Composite structure. Wherein the consumption of sodium silicate is 2mmol; The consumption of ethanol, ammoniacal liquor, deionized water is successively 60ml, 3ml, 20ml, and the consumption of resorcinol is 0.5g, and the consumption of formaldehyde is 0.56ml (the density...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com