Light valve driving control method and device and projection equipment

A light valve and control signal technology, applied in the field of projection display, can solve problems such as light valve damage, mechanical fatigue of the driving device, and inability to distinguish colors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

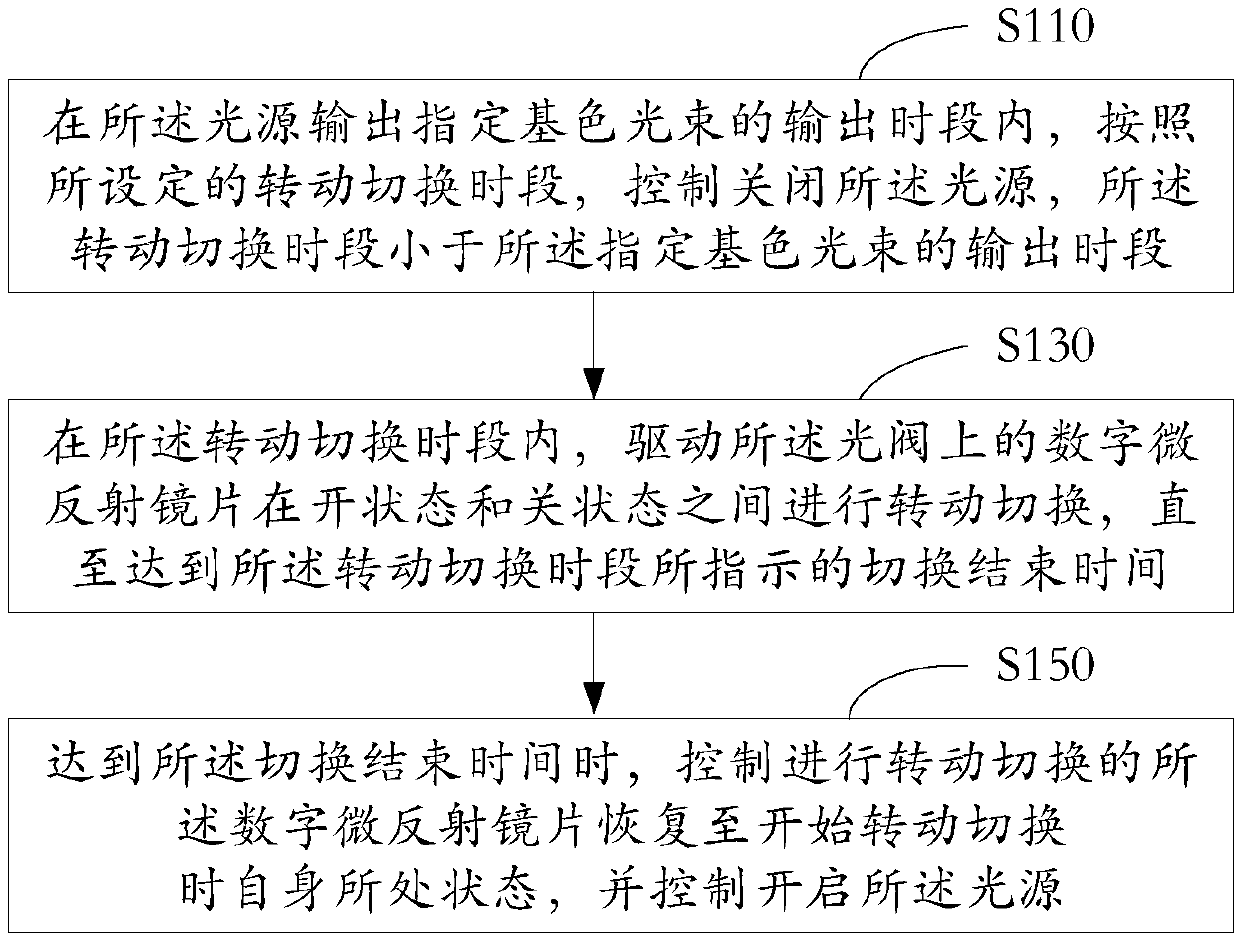

[0030] figure 2 It is a flow chart of a light valve driving control method shown according to an exemplary embodiment. Applied to a light valve composed of a number of digital micro-mirror mirrors, the digital micro-mirror mirrors reflect the primary color light beams sequentially output by the light source for projection display of color images, including:

[0031] Step S110, during the output period of the light source outputting the specified primary color light beam, control to turn off the light source according to the set rotation switching period, and the rotation switching period is shorter than the output period of the specified primary color light beam.

[0032] Step S130, within the rotation switching period, drive the digital micro-reflector on the light valve to switch between the on state and the off state until the switching end time indicated by the rotation switching period is reached.

[0033] Step S150 , when the switching end time is reached, control the ...

Embodiment 2

[0046] In one embodiment, the designated primary color light beam is a blue light beam. Compared with red and green, the human eye has the least sensitivity to blue, and blue contributes the least to the brightness of the displayed image. Therefore, the rotation switching period is configured within the output period of the light source outputting blue light beams, even when the rotation switching When the light source is turned off during the time period, the brightness of the projected and displayed image has little change, which cannot be distinguished by human eyes, thereby reducing the impact on the brightness of the projected and displayed image.

Embodiment 3

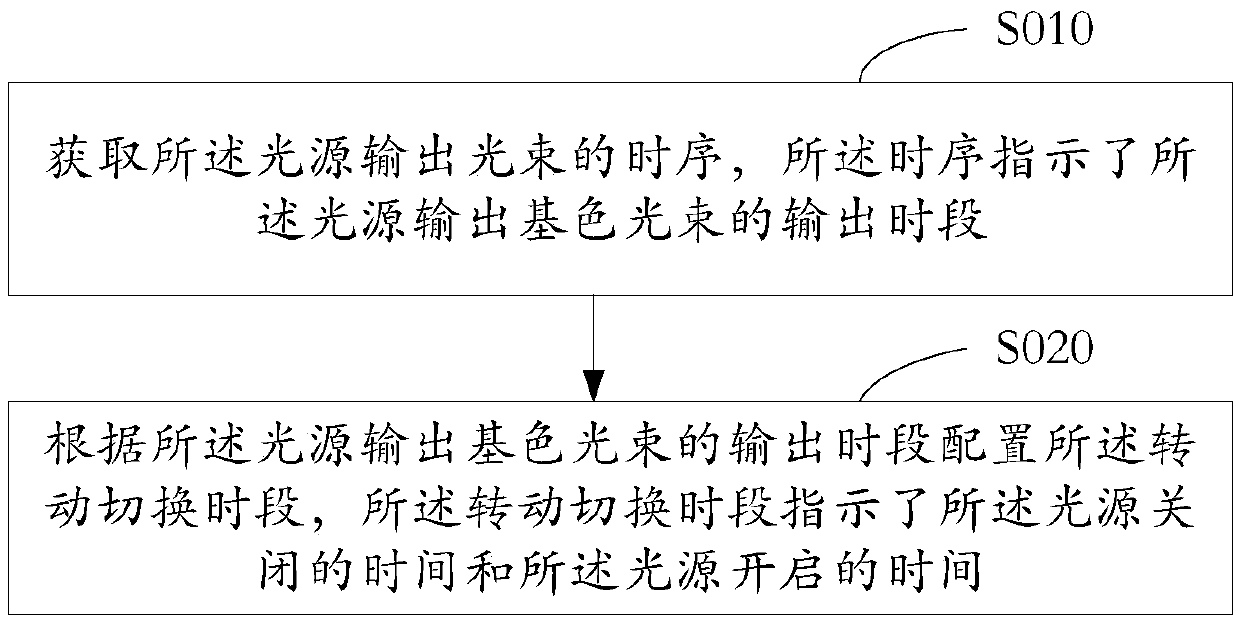

[0048] In one embodiment, as image 3 As shown, the method also includes:

[0049] Step S010, acquiring the time sequence of the light source outputting the light beams, the time sequence indicating the output period of the light source outputting the primary color light beams.

[0050] Step S030, configuring the rotation switching period according to the output period of the light source outputting the primary color light beam, and the rotation switching period indicates the time when the light source is turned off and the time when the light source is turned on.

[0051] Since the light source sequentially outputs red, green and blue beams, correspondingly, it has timings for outputting various primary color beams, for example, a timing sequence for blue beams. Correspondingly, the rotation switching period is configured according to the output period of the light source outputting the primary color light beam. Therefore, it is ensured that both the start time and the end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com