Dissolved oxygen sensor calibration device and calibration method based on fluorescence quenching principle

A dissolved oxygen sensor and fluorescence quenching technology, applied in the field of measurement, can solve the problems of poor stability, low efficiency and high cost, and achieve the effect of reducing operation difficulty, shortening time, avoiding damage and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

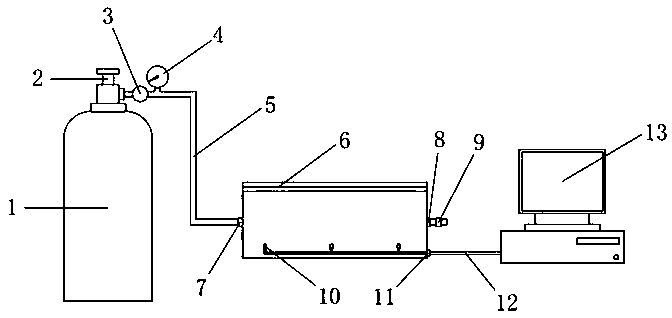

[0058] like figure 1 As shown, the present invention discloses a dissolved oxygen sensor calibration device based on the principle of fluorescence quenching, which includes a plurality of gas cylinders 1 filled with different proportions of oxygen-nitrogen mixed gas, and each gas cylinder is equipped with a main valve 2 connected to the reducing Pressure valve 3 and pressure gauge 4 to control the outlet air pressure; the outlet end of pressure reducing valve 3 is connected to airtight container 6 through pipeline 5; 3-5 temperature sensors 10 are installed in airtight container 6, and through data transmission line 12 and upper position Machine 13 is connected.

[0059] The number of gas cylinders 1 is consistent with the number of calibration points determined earlier. The airtight container 6 is provided with an air inlet 7 and an air outlet 8; wherein the air inlet 7 is connected to the outlet end of the pressure reducing valve 3 through a pipeline 5, and is used to send ...

Embodiment 2

[0066] The present invention also proposes a calibration method for a dissolved oxygen sensor calibration device based on the principle of fluorescence quenching in Embodiment 1. The calibration method specifically includes the following steps:

[0067] S1: According to the experimental conditions and actual application requirements, determine the number of calibration points and the approximate range of the dissolved oxygen concentration corresponding to each calibration point. Different proportions of standard gases are filled in cylinder 1, and the filling pressure is not lower than 5MPa;

[0068] S2: Open the sealing cover of the airtight container 6, put the dissolved oxygen sensor and the temperature sensor 10 to be calibrated into the container, connect the power supply and the communication assembly (the external power line and the data transmission line 12 are drawn from the cable outlet 11), ensure that it can Normal work and normal communication with the upper compu...

Embodiment 3

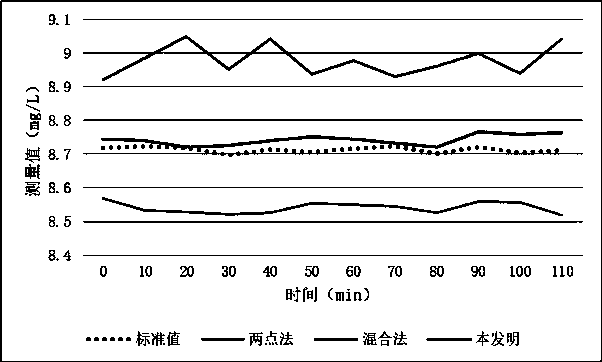

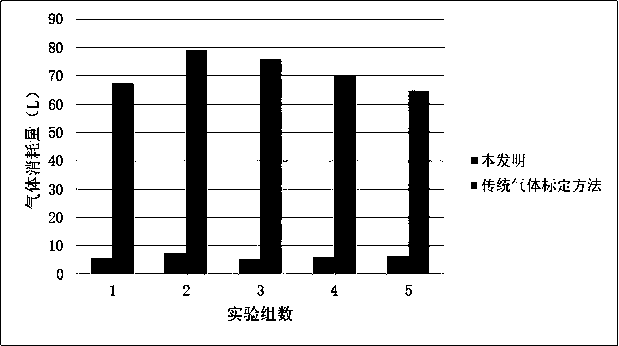

[0081] This embodiment is a comparative experiment: calibrate three dissolved oxygen sensors based on the principle of fluorescence quenching with the same model and service life, respectively using the two-point calibration method commonly used in the industry, the gas mixing method and the calibration method proposed by the present invention; After the calibration is completed, use three sensors to test the same standard sample multiple times under constant temperature and constant pressure conditions, with an interval of 10 minutes between the two tests, and record the measurement results of each sensor; The sensor is used as a standard reference, and its calibration effect is compared. The measurement results are as follows: figure 2 shown.

[0082] It can be seen that compared with several commonly used calibration methods in the industry, the calibration method proposed by the present invention has significant advantages in the accuracy and repeatability of the measurem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com