Semiconductor strain balance applied to pulse wind tunnel

A technology of strain balances and semiconductors, which is used in the testing, measuring devices, instruments, etc. of machine/structural components, which can solve the problem that the stiffness of the strain balance cannot be satisfied, the frequency response cannot be satisfied, the strain design of the strain balance cannot be too small, and the sensitivity coefficient of the resistance strain gauge is low. and other problems, to achieve the effect of improving sensitivity and measurement accuracy, enhancing stiffness, and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Such as figure 1 As shown, the semiconductor strain balance applied to the pulse wind tunnel of the present invention includes a model connecting section 1, a first combined measuring element 2, an axial force measuring element 3, a second combined measuring element 4, and an accelerometer mounting section from front to back 5. Balance pole 6 and support section 7;

[0034] Such as figure 2 As shown, the model connection section 1 is a cone section that expands from front to back, and is connected with the wind tunnel test model through the cone surface. The keyway 11 is provided on the cone surface, which is used for the installation and positioning of the wind tunnel test model, and the model connection The front end of section 1 is provided with a threaded hole 12, which is used for compacting the wind tunnel test model;

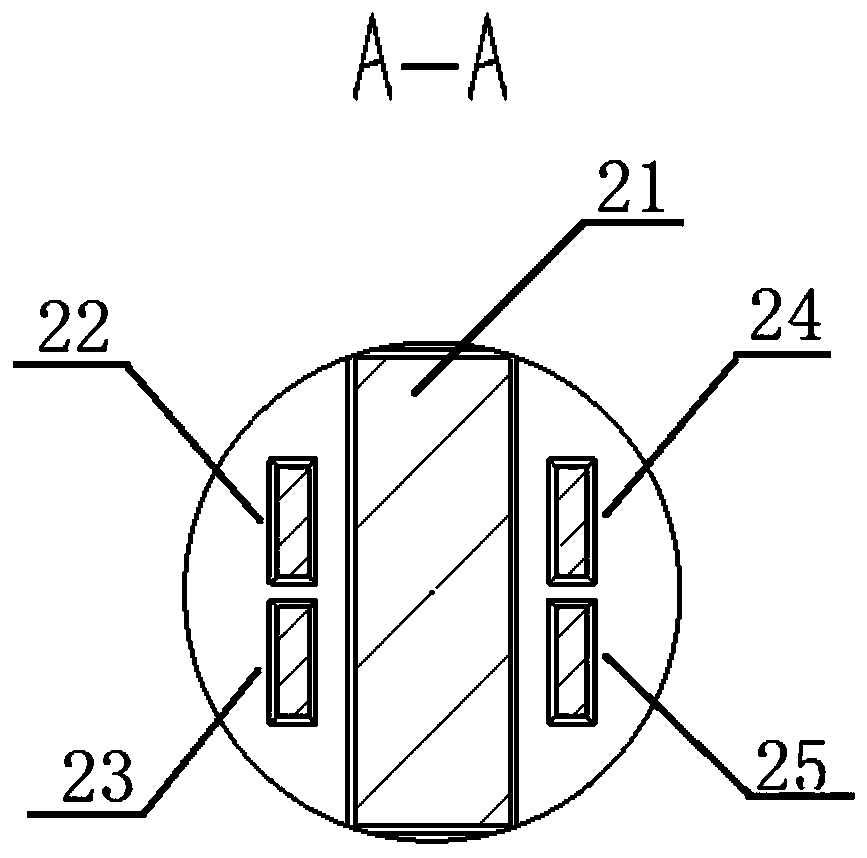

[0035] Such as figure 2 , 3 As shown, the first combined measuring element 2 is a five-piece beam structure, and the five-piece beam structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com