Truss rib laminated plate with height limiting devices, die table assembly and production process thereof

A production process and technology of laminated board, applied in the direction of mold auxiliary parts, floors, building components, etc., can solve problems such as extrusion deformation, laminated board damage, bottom plate cracking, etc., to achieve high strength, high precision, and reduce the height of the mold table. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

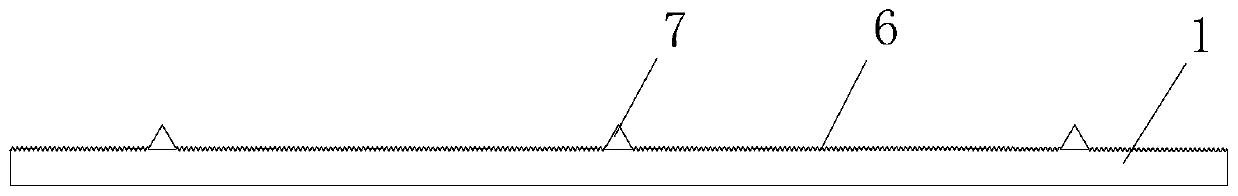

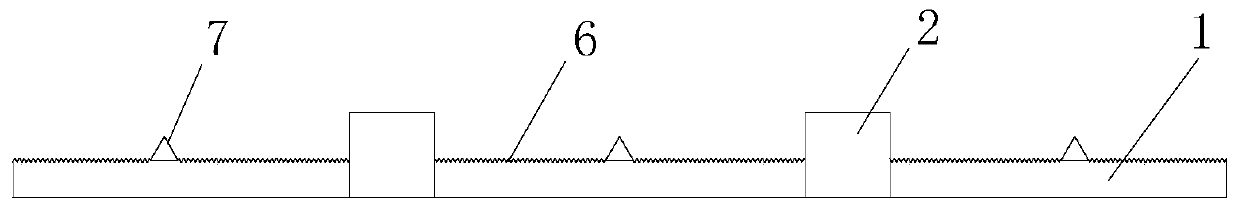

[0055] like figure 2As shown, the present invention provides a truss bar laminated slab with a height limiting device, which includes a prefabricated base plate 1 and a cast-in-place layer. The truss bars 7 are located on the same side, and the height of each height limiting device exposed outside the prefabricated floor 1 is equal to the thickness of the cast-in-place layer.

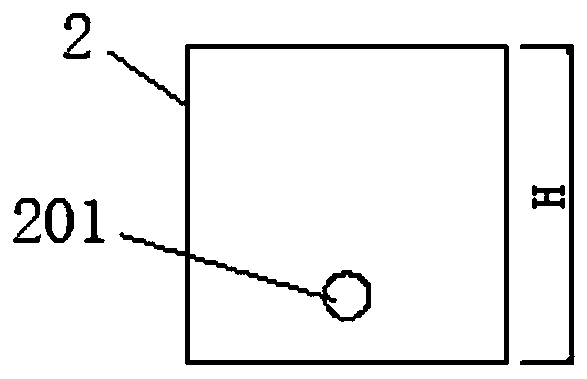

[0056] In the embodiment of the present invention, the height-limiting device includes a height-limiting pier 2, and the height-limiting pier 2 and the prefabricated floor 1 are poured into an integrated structure.

[0057] Further, the height-limiting pier 2 is provided with a fixed engagement structure with the prefabricated floor 1 during pouring.

[0058] In the embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com