Full-automatic loudspeaker coil winding machine

A loudspeaker, fully automatic technology, applied in the field of loudspeakers, can solve the problems of increasing the defective rate, wasting human resources, and unqualified coil quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

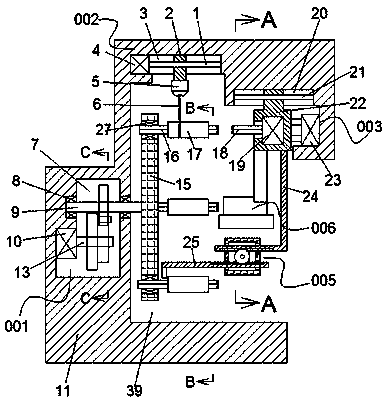

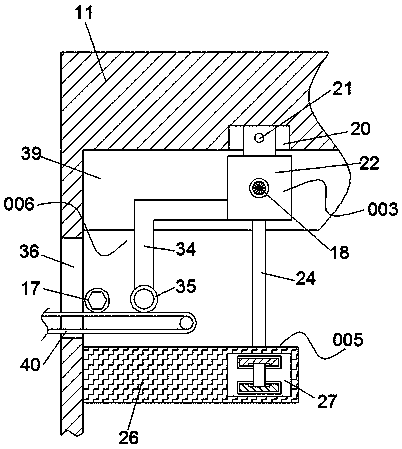

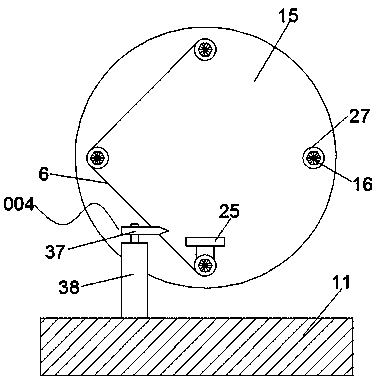

[0019] Combine below Figure 1-6 The present invention is described in detail, and for convenience of description, the orientations mentioned below are now stipulated as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0020] refer to Figure 1-6 According to an embodiment of the present invention, a device body 11 is provided with a winding chamber 39 in the right side end surface, and a drive chamber 7 is provided in the left side of the device body 11, and the drive chamber 7 is connected to the winding chamber 39. A No. 1 rotating shaft 9 is communicated between the line chambers 37, and the No. 1 rotating shaft 9 is installed in the left and right walls of the driving chamber 7 through the No. 1 bearing 8. The driving chamber 7 is provided with a No. 1 rotating shaft 9 intermittently rotates the intermittent No. 1 driving device 001, and the No. 1 rotating shaft 9 located on the left side wall o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com