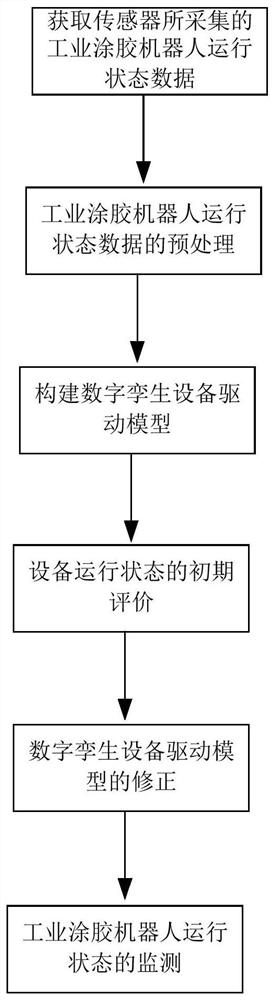

A method for monitoring the operating status of an industrial gluing robot based on digital twin technology

A technology of operating state and robot, which is applied in the direction of manipulators, manufacturing tools, program control manipulators, etc., and can solve difficult problems such as operating state and prediction of industrial gluing robots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

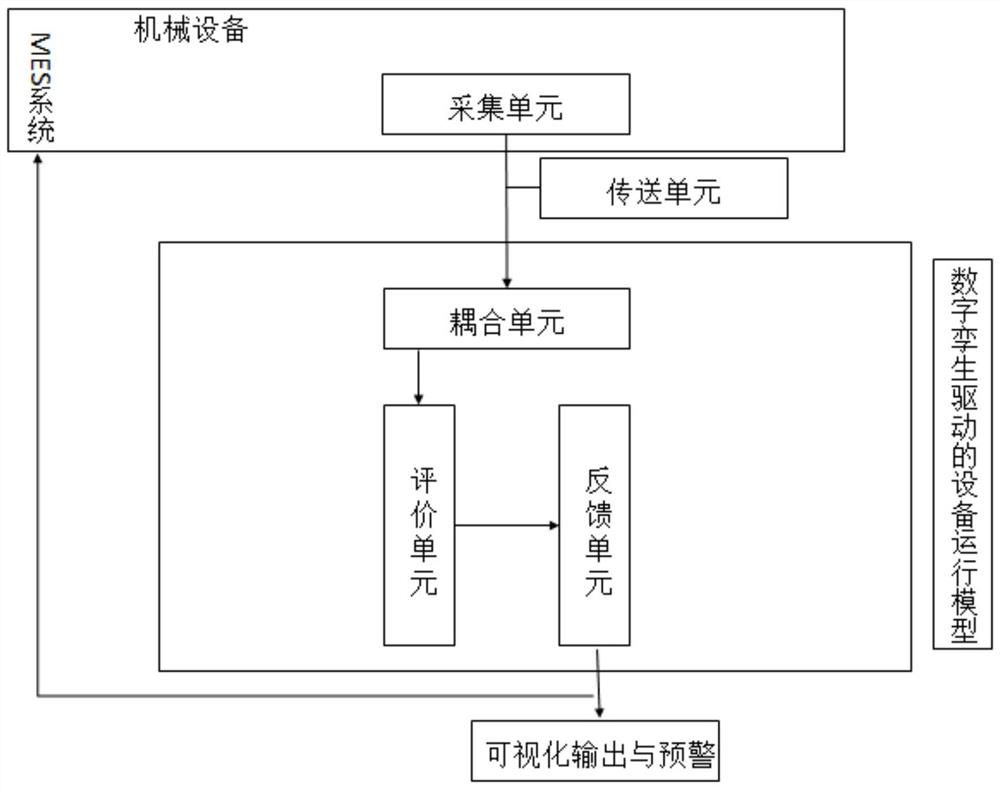

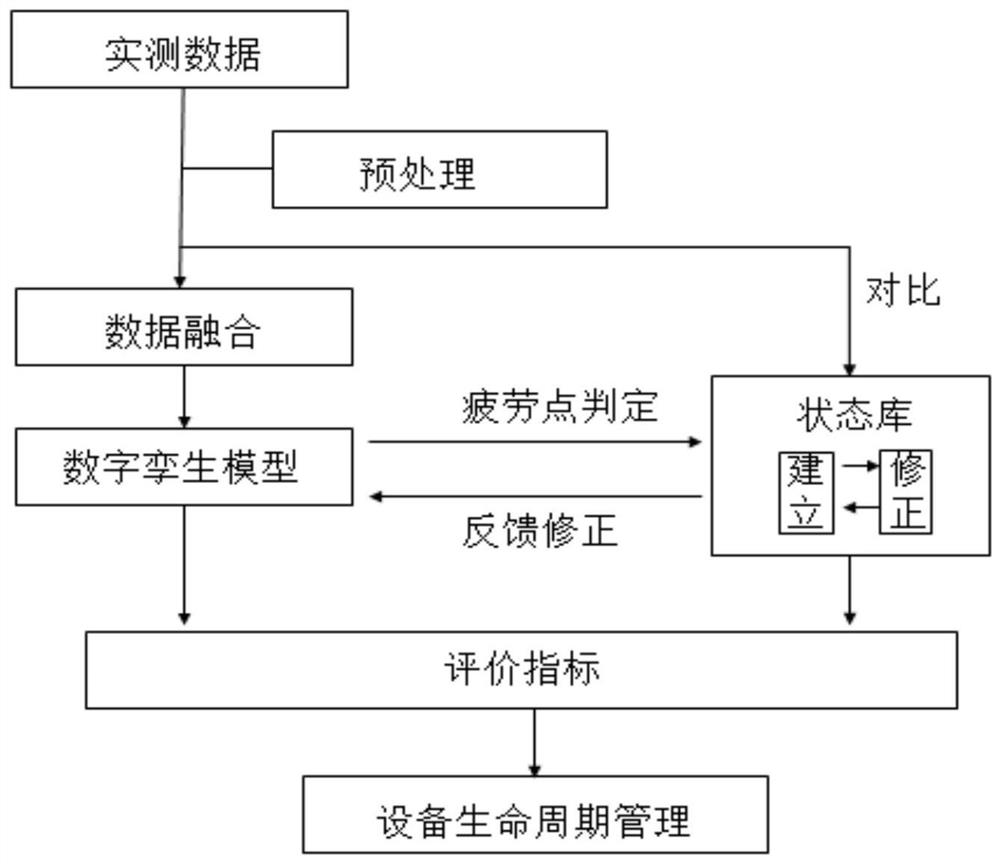

Method used

Image

Examples

Embodiment Construction

[0053] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

[0054] The industrial gluing robot applied in the present invention includes a reciprocating joint assembly, and the reciprocating joint assembly includes components such as a working arm, a gripper, a camera, and a glue spraying device. The relevant parts of the reciprocating joint assembly are installed with sensors for obtaining three-dimensional value of position information, the front end of the operating arm of the reciprocating joint assembly is equipped with an attitude sensor, and the image acquisition range of the image acquisition device (camera, high-speed camera) is located at the front end of the operating arm. The monitoring range of the potential difference monitoring terminal (error analyzer, infrared observer) is loca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com