A sound barrier main girder keel riveting assembly device

An assembly device and sound barrier technology, which is applied in the field of sound barrier main girder keel rivet assembly devices, can solve the problem of complex and occupied space of the sound barrier assembly mechanism, avoid weakening of plate strength, increase reliability, redundancy, and structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

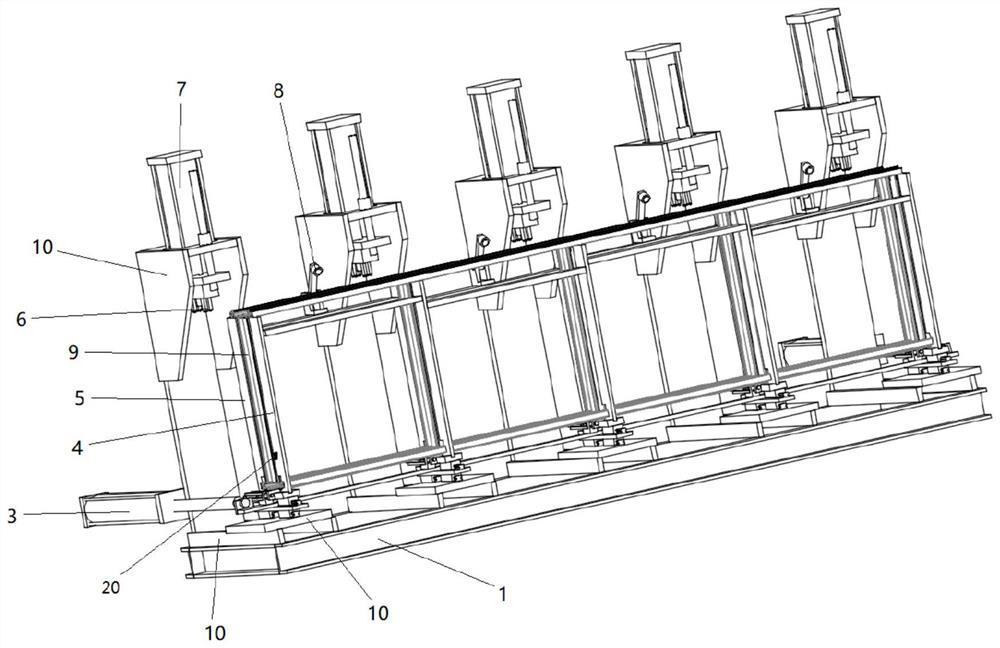

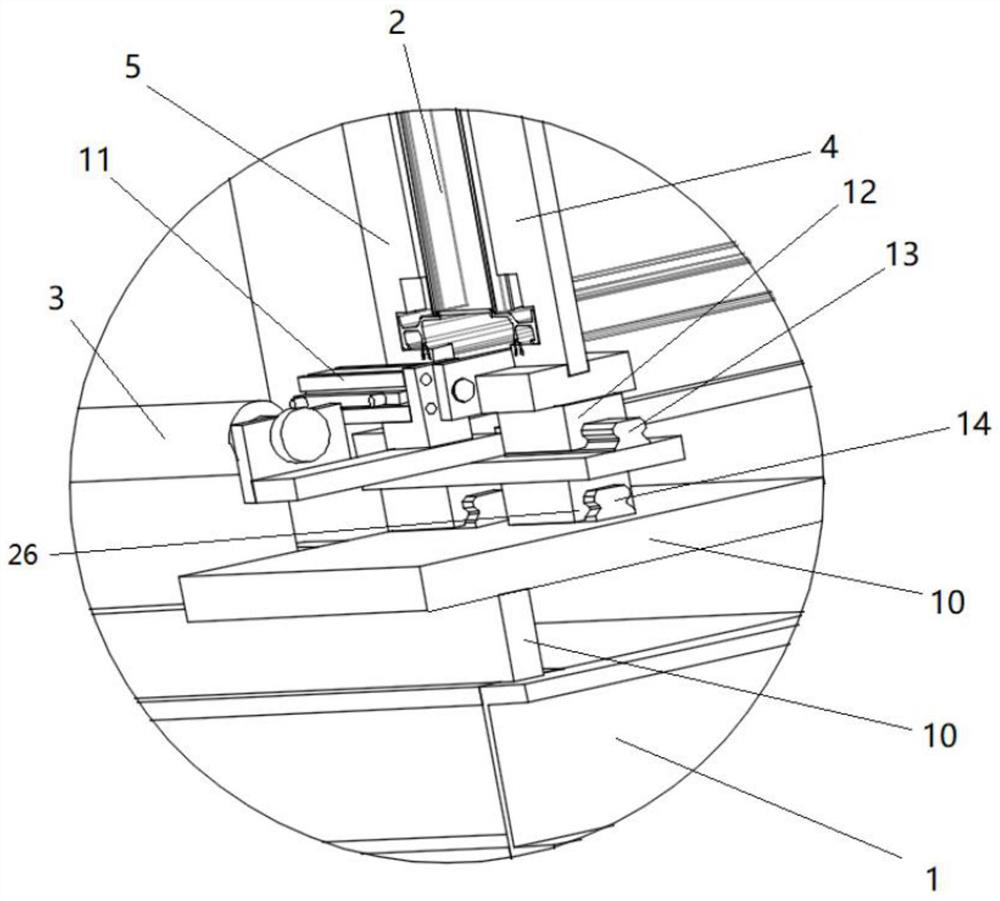

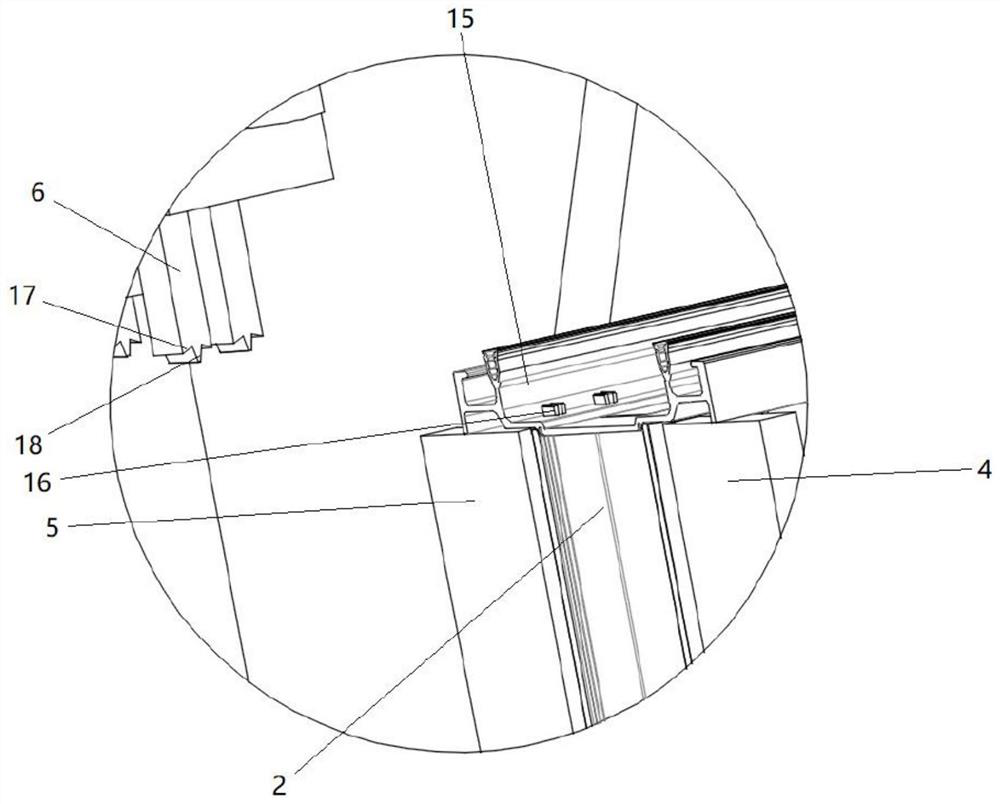

[0023] like Figure 1 to Figure 7 In the shown embodiment, a sound barrier main girder keel rivet 9 assembly device, the lowermost end is an assembly frame 1, and several groups of assembly units are bolted to the assembly frame 1, and each assembly unit includes a bracket 10, a prefabricated Subcomponents such as frames. The bracket 10 is used to connect the various sub-components of the assembled unit and at the same time acts as a fixing surface. The prefabricated frame is composed of two parts, the first prefabricated frame 5 and the second prefabricated frame 4, wherein the first prefabricated frame 5 is welded on a pallet, and a first slide rail 13 is also provided on the pallet, and the second prefabricated frame 4 The lower end surface of the frame is provided with a first chute 12, and the first chute 12 cooperates with the first slide rail 13 to realize the sliding connection between the second prefabricated frame 4 and the pallet. The first driving device 11 is a cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com