Hair care essential oil, hair care essential oil processing system and hair care essential oil processing method

A processing system and essential oil technology, applied in essential oils/fragrances, hair care, pharmaceutical formulations, etc., can solve problems such as damaged knives, achieve full extraction, avoid uneven processing, and improve crushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

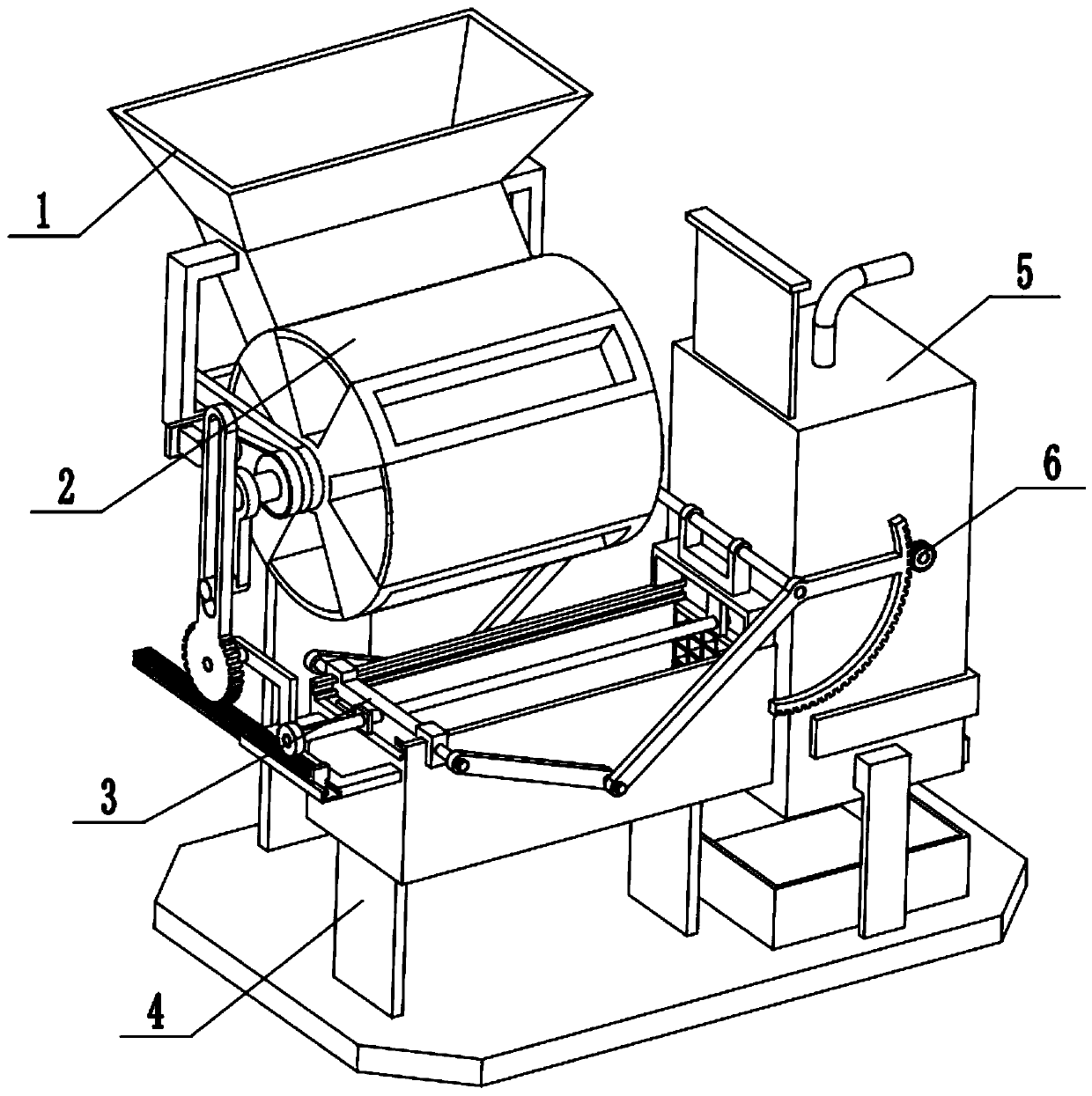

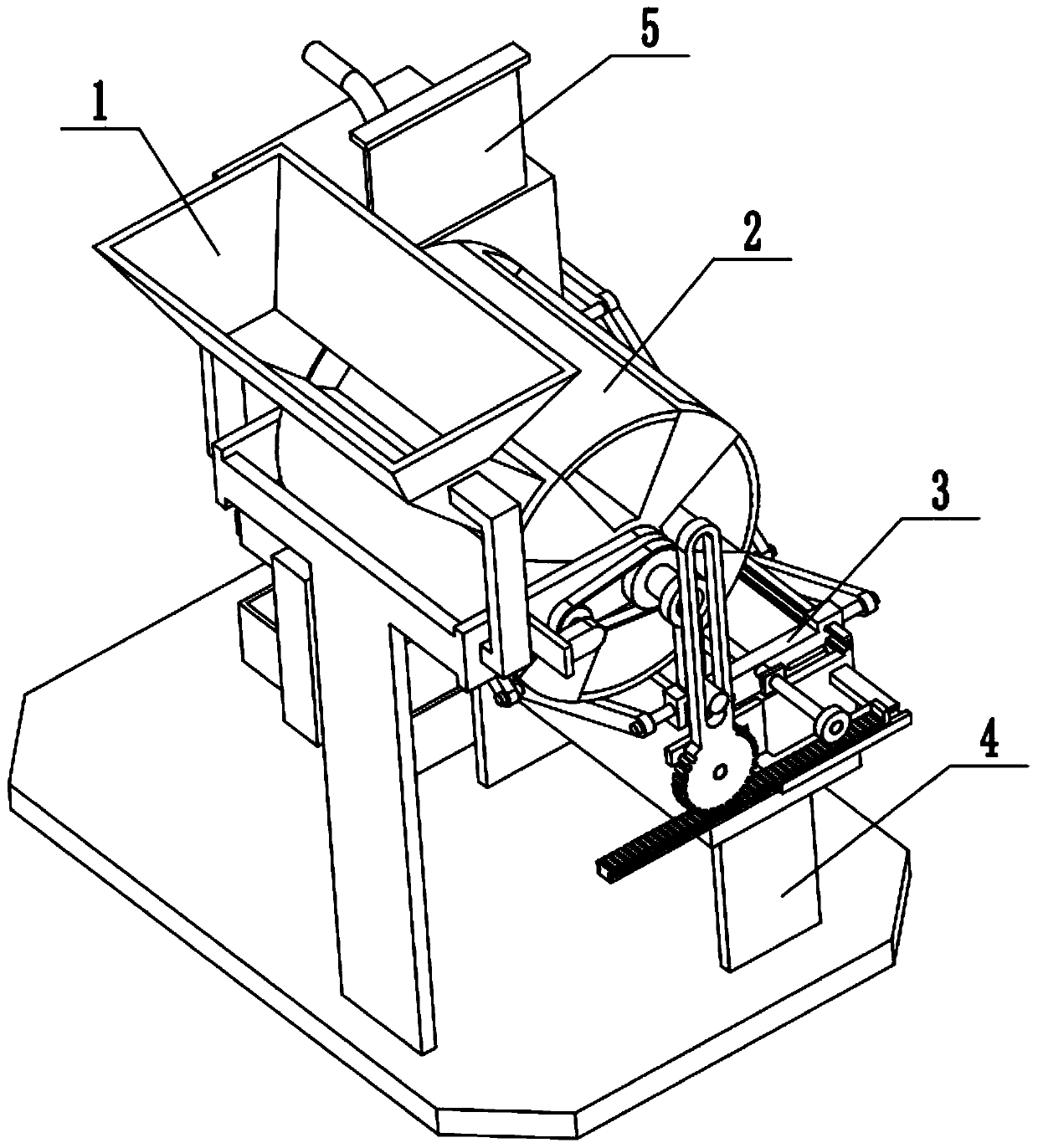

[0037] Combine below Figure 1-10 Describe this embodiment, a hair care essential oil processing system, including a feeding device 1, a dispersing feeding mechanism 2, a pushing mechanism 3, a base assembly 4, a distillation device 5 and a crushing device 6, and the feeding device 1 is set on the base assembly 4, the dispersed feeding mechanism 2 is set on the feeding device 1, the dispersed feeding mechanism 2 is connected with the feeding device 1, the push mechanism 3 is connected with the base assembly 4, the dispersed feeding mechanism 2 is connected with the pushing mechanism 3, and the distillation The device 5 is arranged on the base assembly 4, the distillation device 5 abuts against the base assembly 4, the pushing mechanism 3 is located on one side of the distillation device 5, the crushing device 6 is arranged inside the distillation device 5, and the pushing mechanism 3 drives the crushing device 6 to rotate. When in use, put the rod-shaped raw materials into the...

specific Embodiment approach 2

[0039] Combine below Figure 1-10 To illustrate this embodiment, the feeding device 1 includes a feed hopper 1-1, a material guide box 1-2, a fixed frame 1-3, a first motor 1-4 and a first pulley 1-5; the feed hopper 1-1 is fixedly connected and communicated with the material guide box 1-2, the material guide box 1-2 is fixedly connected on the fixed frame 1-3, the fixed frame 1-3 is arranged on the base assembly 4, and the dispersed feeding mechanism 2 is connected with the fixed The frame 1-3 is connected, the first motor 1-4 is fixedly connected on the fixed frame 1-3 through the motor frame, the first pulley 1-5 is fixedly connected on the output shaft of the first motor 1-4, and the first pulley 1-5 are connected with the transmission of the dispersing feeding mechanism 2. The longer or larger-diameter rod-shaped raw materials are put into the feed hopper 1-1, and the first motor 1-4 is started to drive the dispersing and unloading mechanism 2 to work through the first p...

specific Embodiment approach 3

[0041] Combine below Figure 1-10 To illustrate this embodiment, the dispersing and feeding mechanism 2 includes a rotating shaft 2-1, a distribution hopper 2-2, an arc-shaped baffle plate 2-3, a drive shaft 2-4, a second pulley 2-5, Rotating rod 2-6, driving rod 2-7, grooved rod 2-8, first gear 2-9, gear rotating shaft 2-10, axle frame 2-11, sliding seat 2-12, T-shaped groove 2-13, I-shaped plate 2-14 and the first rack 2-15; four distribution hoppers 2-2 are evenly distributed on the rotating shaft 2-1, and the four arc-shaped baffles 2-3 are spaced from the four distribution hoppers 2-2 Staggered setting, the cross section of the four arc-shaped baffles 2-3 and the four sub-hoppers 2-2 is circular, and the lower end of the material guide box 1-2 is connected to the four sub-hoppers 2-2 and the four arc-shaped baffles. The circumferential end faces formed by the material plates 2-3 are bonded, the rotating shaft 2-1 is fixedly connected to the drive shaft 2-4, the drive sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com