Threshing cylinder with adjustable threshing diameter, adjusting method and combine harvester

A threshing drum and diameter adjustment technology, which is applied in the direction of harvesters, threshing equipment, cutters, etc., can solve the problems of small improvement in the threshing adaptability of combine harvesters, uneven threshing gaps, and inability to change the linear speed of threshing components. Achieve the effects of improving adaptability and harvesting efficiency, improving conveying capacity, and convenient and quick adjustment methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

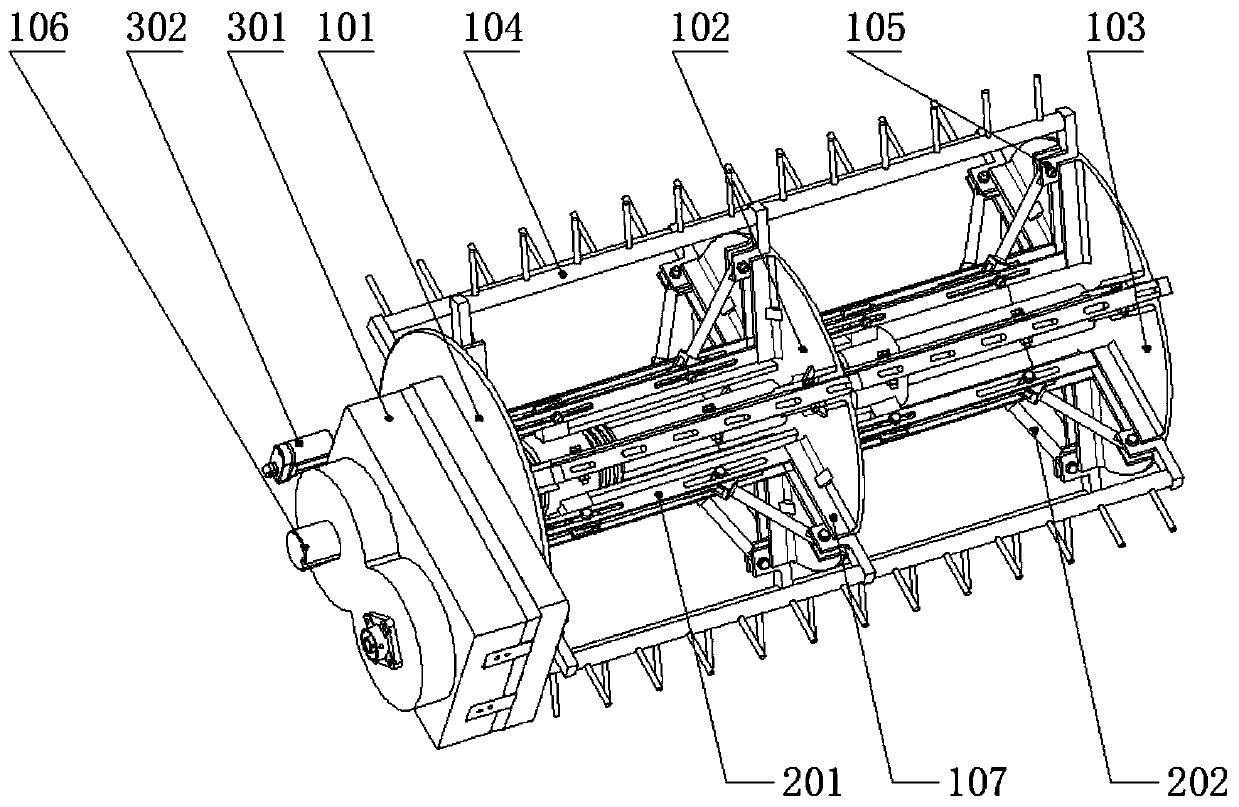

[0030] Such as figure 1 As shown, the diameter-adjustable threshing cylinder of the present invention includes a threshing cylinder, a diameter adjusting device, and a driving device. The head of the threshing cylinder is installed on the outside of the front support disc 101 of the threshing cylinder.

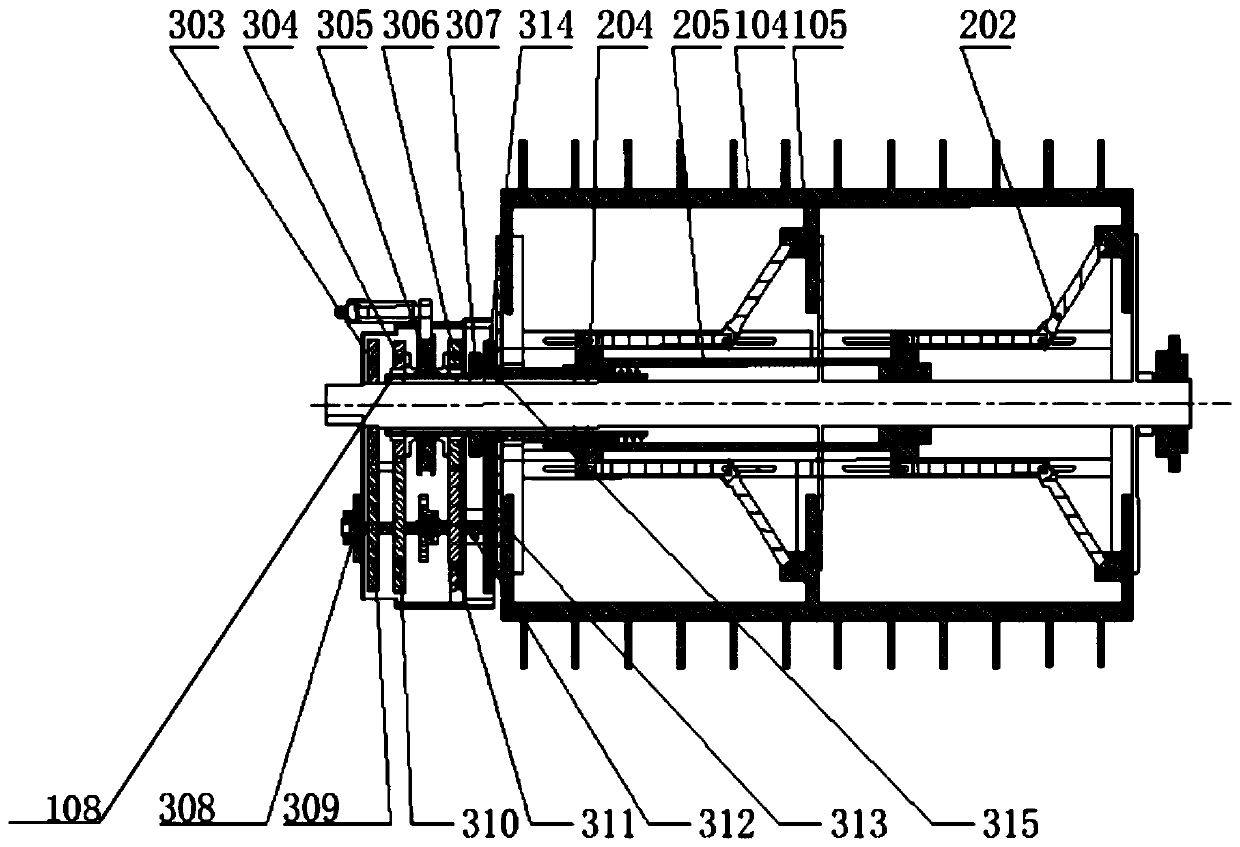

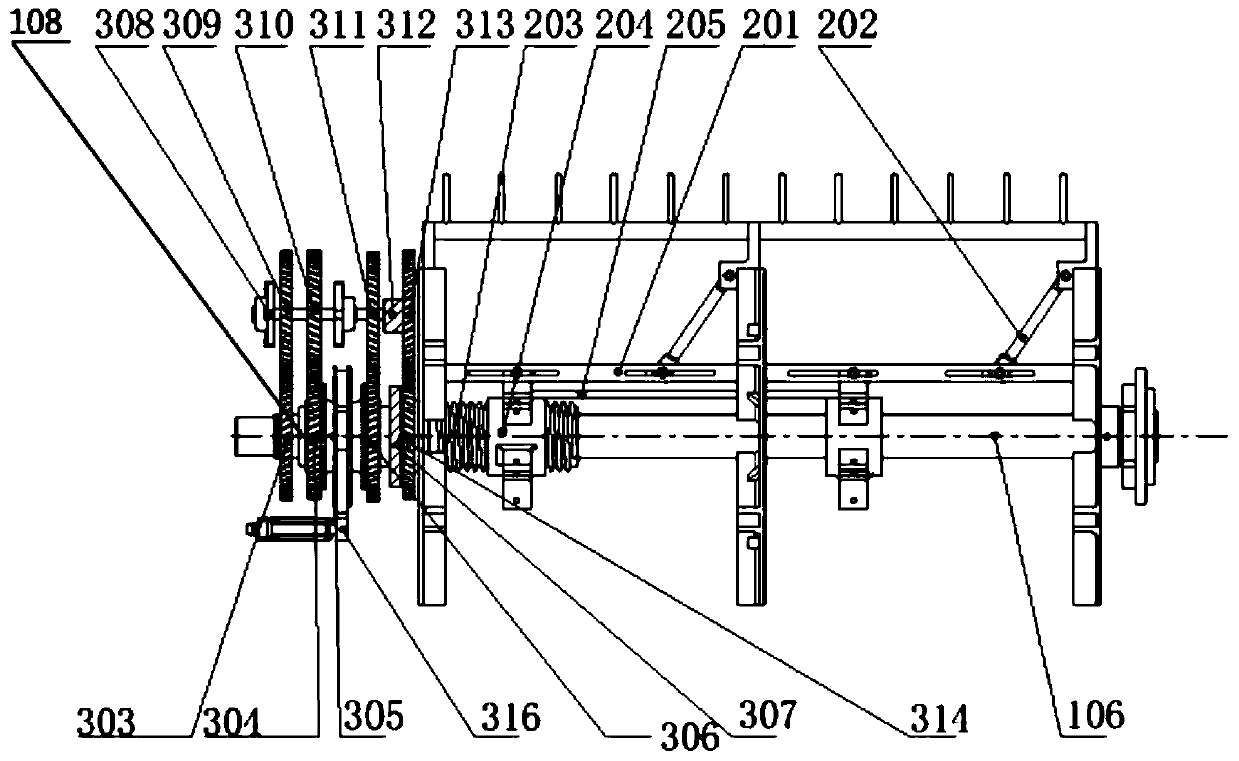

[0031] The threshing drum includes a drum shaft 106, and the front support disc 101, the middle support disc 102, and the rear support disc 103 are installed on the drum shaft 106 from front to back along the power transmission direction, and are installed on the front support disc 101. 1. Rear support disc 103, rear support threshing rack 105 on the disc 103, said threshing rack 105 can move radially in the threshing cylinder. Specifically, in this embodiment, the thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com