Convex profile and application method thereof

A profile and connecting plate technology, applied in the installation of rack/frame structure, electrical components, support structure, etc., can solve the problems of complex assembly method, low degree of generalization of spare parts in the cabinet, unfavorable standardization, mass production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

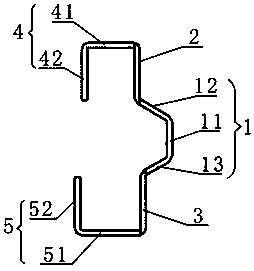

[0105] like figure 1 As shown, a convex profile includes a C-shaped connecting plate 1, an upper vertical plate 2, a lower vertical plate 3, an upper inverted L-shaped plate 4 and a lower L-shaped plate 5, and the C-shaped connecting plate 1 includes a bottom plate 11 and the upper connection plate 12 and the lower connection plate 13 connected to the two ends of the bottom plate 11;

[0106] The upper inverted L-shaped plate 4 is composed of a vertically connected upper horizontal plate 41 and an upper vertical plate 42, and the lower L-shaped plate 5 is composed of a vertically connected lower horizontal plate 51 and a lower vertical plate 52. The C-shaped connection The end of the upper connecting plate 12 of the plate 1 is connected to the lower end of the upper vertical plate 2, and the end of the lower connecting plate 13 is connected to the upper end of the lower vertical plate 3; the upper end of the upper vertical plate 2 is vertically connected to the upper horizont...

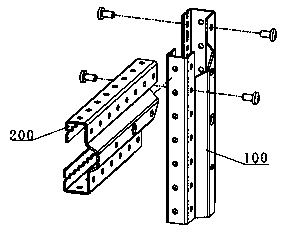

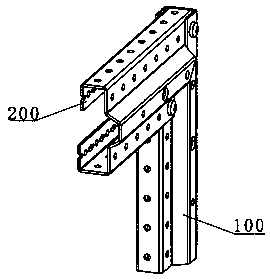

Embodiment 2

[0134] like Figure 11 As shown, a convex profile includes a C-shaped connecting plate 1, an upper vertical plate 2, a lower vertical plate 3, an upper inverted L-shaped plate 4 and a lower L-shaped plate 5, and the C-shaped connecting plate 1 includes a bottom plate 11 and the upper connection plate 12 and the lower connection plate 13 connected to the two ends of the bottom plate 11;

[0135] The upper inverted L-shaped plate 4 is composed of a vertically connected upper horizontal plate 41 and an upper vertical plate 42, and the lower L-shaped plate 5 is composed of a vertically connected lower horizontal plate 51 and a lower vertical plate 52. The C-shaped connection The end of the upper connecting plate 12 of the plate 1 is connected to the lower end of the upper vertical plate 2, and the end of the lower connecting plate 13 is connected to the upper end of the lower vertical plate 3; the upper end of the upper vertical plate 2 is vertically connected to the upper horizon...

Embodiment 3

[0142] like Figure 18 As shown, a convex profile includes a C-shaped connecting plate 1, an upper vertical plate 2, a lower vertical plate 3, an upper inverted L-shaped plate 4 and a lower L-shaped plate 5, and the C-shaped connecting plate 1 includes a bottom plate 11 and the upper connection plate 12 and the lower connection plate 13 connected to the two ends of the bottom plate 11;

[0143] The upper inverted L-shaped plate 4 is composed of a vertically connected upper horizontal plate 41 and an upper vertical plate 42, and the lower L-shaped plate 5 is composed of a vertically connected lower horizontal plate 51 and a lower vertical plate 52. The C-shaped connection The end of the upper connecting plate 12 of the plate 1 is connected to the lower end of the upper vertical plate 2, and the end of the lower connecting plate 13 is connected to the upper end of the lower vertical plate 3; the upper end of the upper vertical plate 2 is vertically connected to the upper horizon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com