Automatic cutting device for pre-stressed high-strength concrete (PHC) tubular piles

An automatic cutting device, the technology of PHC pipe piles, applied in the direction of stone processing tools, manufacturing tools, stone processing equipment, etc., can solve the problems of a wide range of building types, easy deflection of pile head cutting, time-consuming and laborious cutting, etc. Good effect, cutting time and labor saving, novel and simple structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

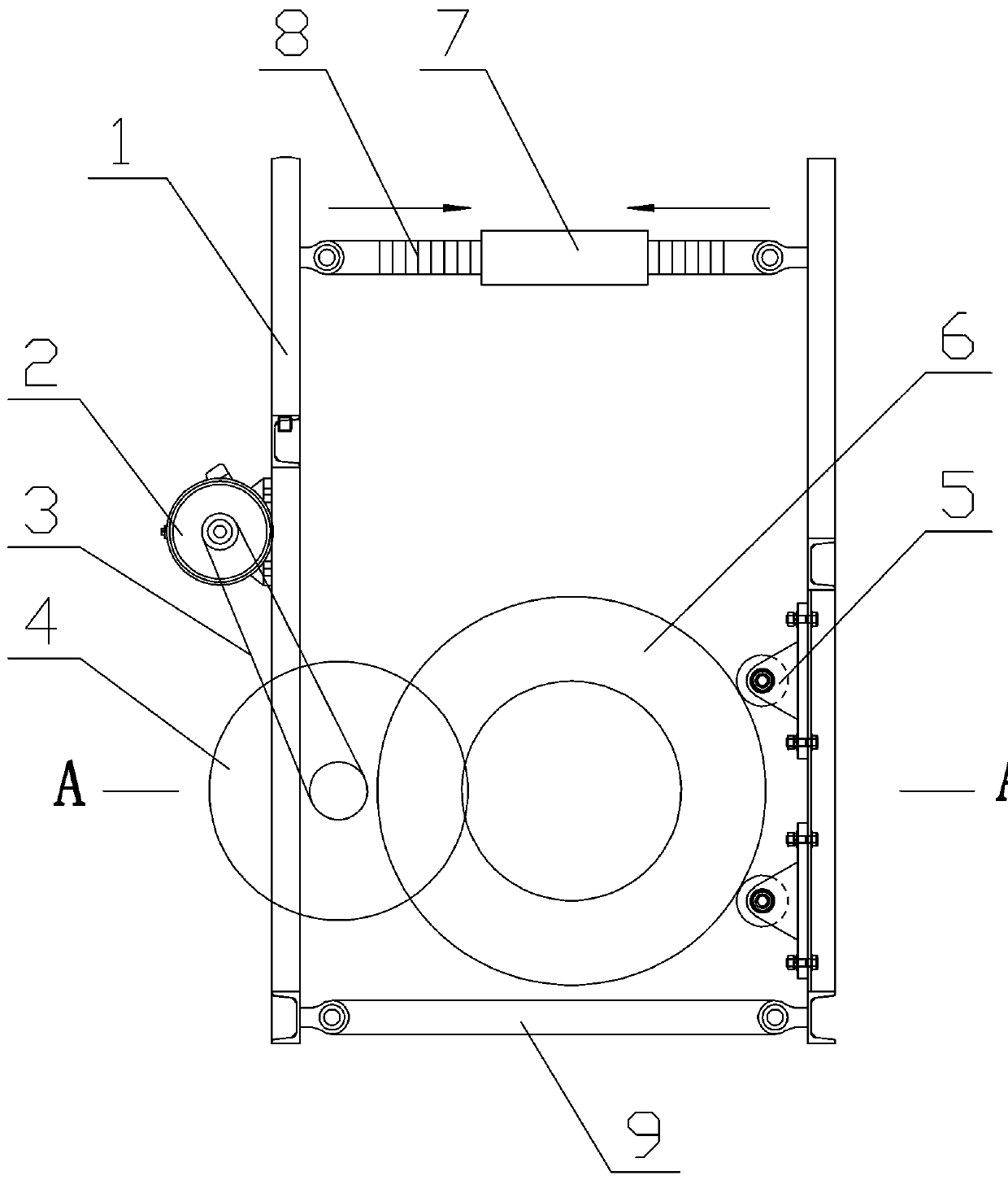

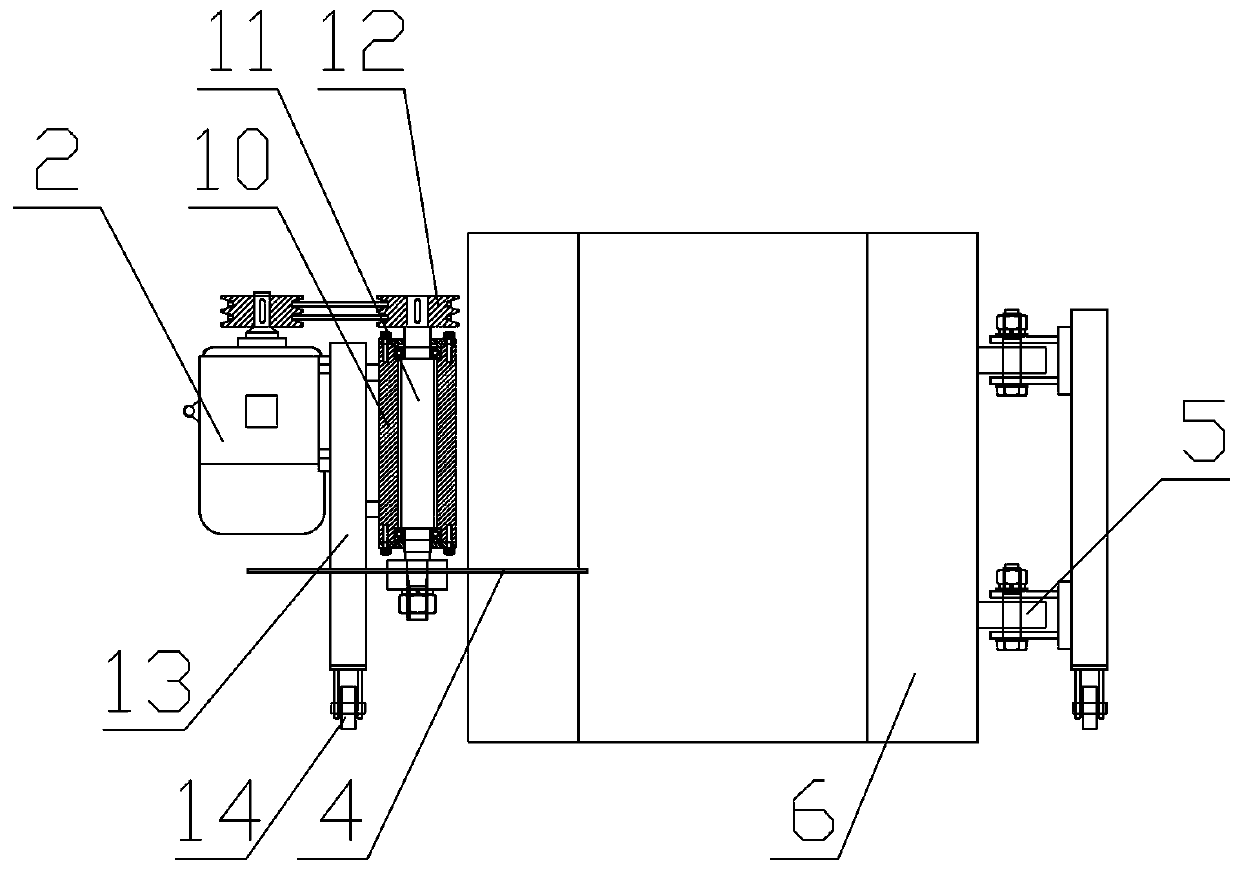

[0012] see figure 1 , figure 2 , the present invention is an automatic cutting device for PHC pipe piles, which has a connecting cross bar 9, a cutting longitudinal bar 1 is hinged at both ends of the connecting cross bar, the front end of the cutting longitudinal bar is hinged with the connecting cross bar, and each cutting Two supporting legs 13 are arranged vertically downward at the bottom of the longitudinal rod, and universal wheels 14 are installed at the bottom of each supporting leg, and at least two groups of tube walls are arranged on the supporting legs below one of the two cutting longitudinal rods. The supporting roller 5 is vertically provided with a cutting motor 2 and a cutting sleeve 10 on the supporting leg below the other one of the two cutting longitudinal bars. A cutting shaft 11 is installed in the cutting sleeve through a bearing, and the upper end of the cutting shaft passes through a belt pulley 12. And transmission belt 3 is connected with cutting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com