Conveyer installation assisting device

An installation aid and conveyor technology, applied in hand-held tools, manufacturing tools, etc., can solve the problems of inaccurate adjustment of tape tightness and low assembly efficiency, and achieve the effect of improving accuracy and consistency and improving installation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

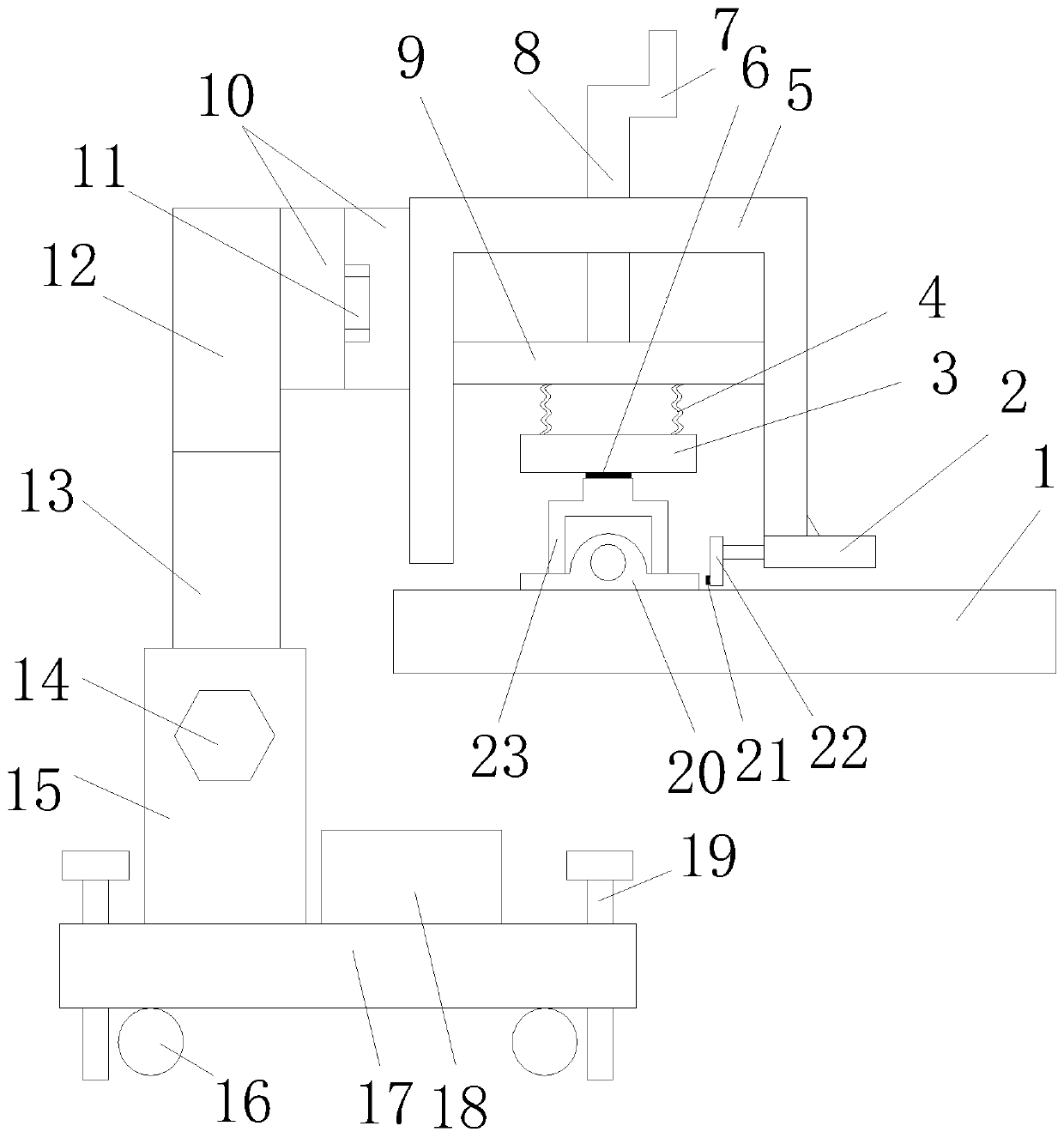

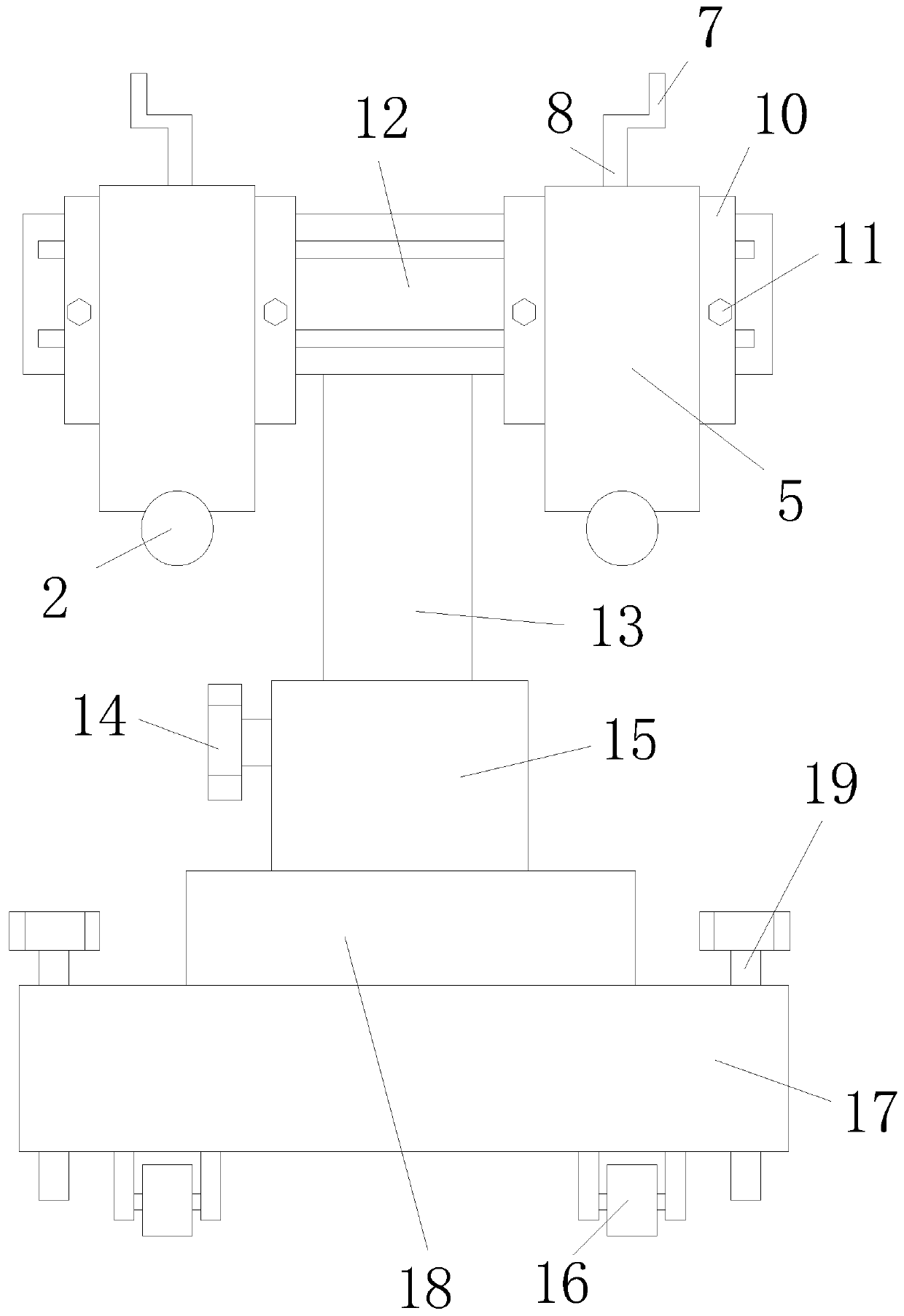

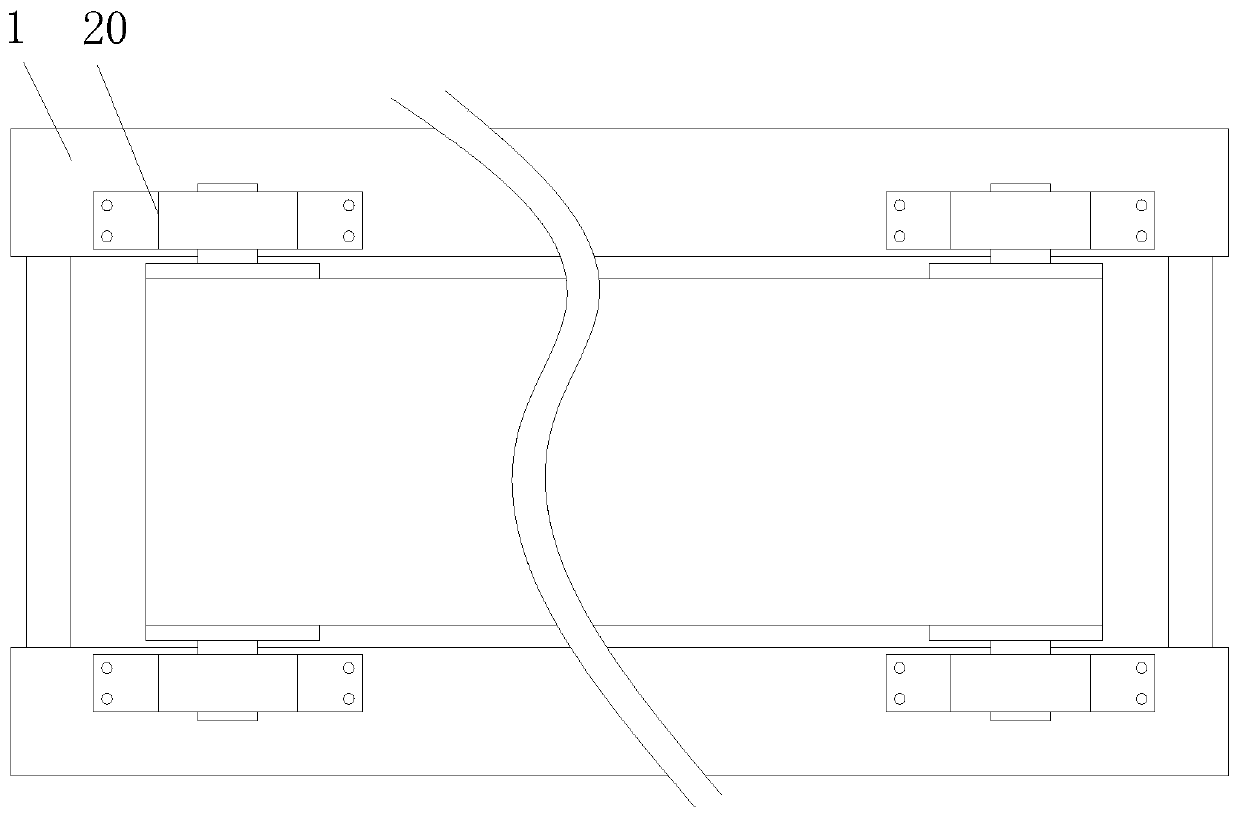

[0016] refer to Figure 1-3 , an auxiliary device for conveyor installation, including a support mechanism, two inverted first U-shaped brackets 5 are connected to the support mechanism, and two vertical plates of the first U-shaped bracket 5 are connected between two vertical plates that can slide up and down. The second permanent magnet plate 9 of the second permanent magnet plate 9 is rotated in the middle of the top of the second permanent magnet plate 9 and is connected with a vertically arranged threaded shaft 8. The threaded shaft 8 runs through the horizontal plate of the first U-shaped support 5, and the threaded shaft 8 is threaded with the horizontal plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com