A coal mine roadway explosion-proof airtight air bag

A coal mine roadway and air bag technology, which is applied in dust prevention, mining equipment, fire prevention, etc., can solve problems such as long construction time and large demand for materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the technical means, creative features, goals and effects of the invention easy to understand, the present invention will be further elaborated below in conjunction with specific illustrations.

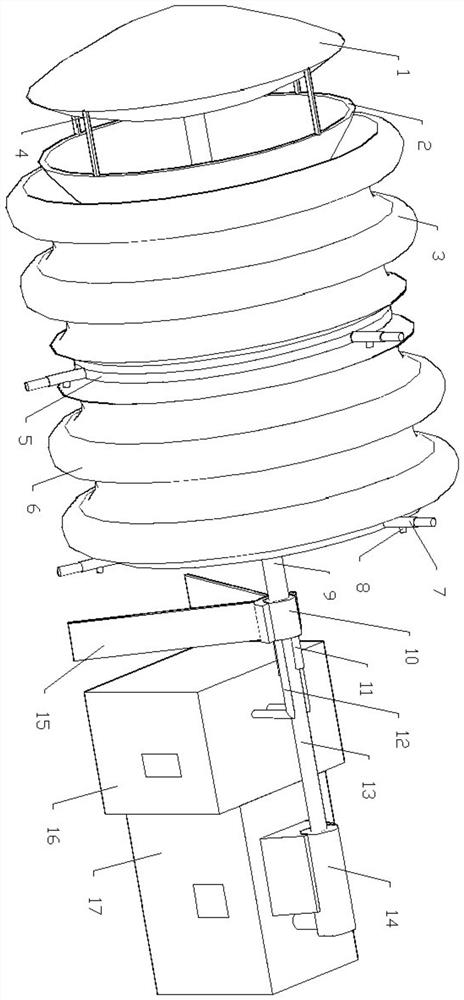

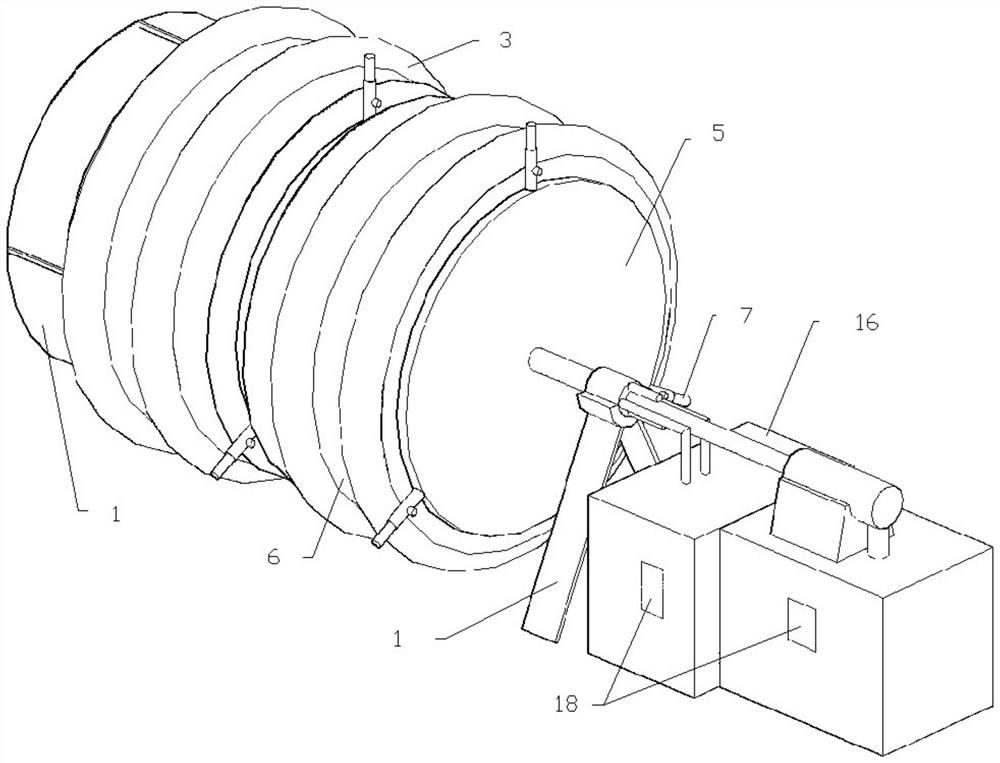

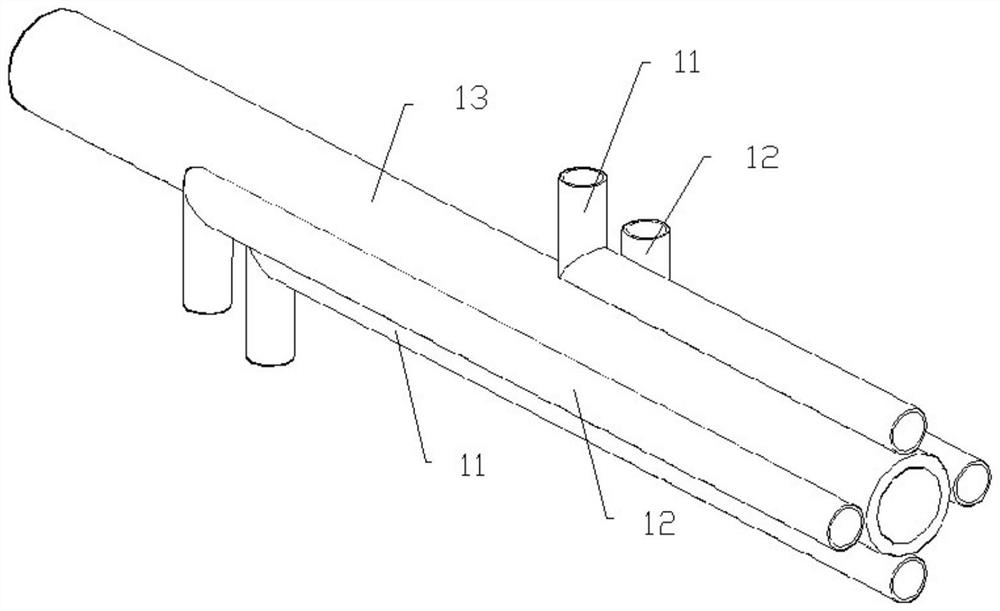

[0018] Such as Figure 1 to Figure 3 As shown, a coal mine roadway explosion-proof airtight airbag, including a hydrogel coagulation bag 1 arranged in sequence from front to back, a circular arc-shaped force plate 2, a first airtight airbag 3, a disc-shaped baffle 5, and a second airtight airbag 6 and the disc-shaped baffle 5, the arc-shaped force plate 2, the first airtight air bag 3, the disc-shaped baffle 5, the second airtight air bag 6 and the inner center of the disc-shaped baffle 5 all pass through the The composite pipeline 9 is connected together and the front of the composite pipeline 9 is communicated and fixed with the hydrogel coagulation bag 1. The disc-shaped baffle 5 is arranged vertically and is provided with three supporting telescopic rods 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com