Construction method of prefabricated wallboard

A construction method and prefabricated technology, applied in the processing of walls, building materials, building components, etc., can solve the problems of high number and strength requirements and troubles of reinforcement parts, and achieve the effect of firm installation and reduced use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

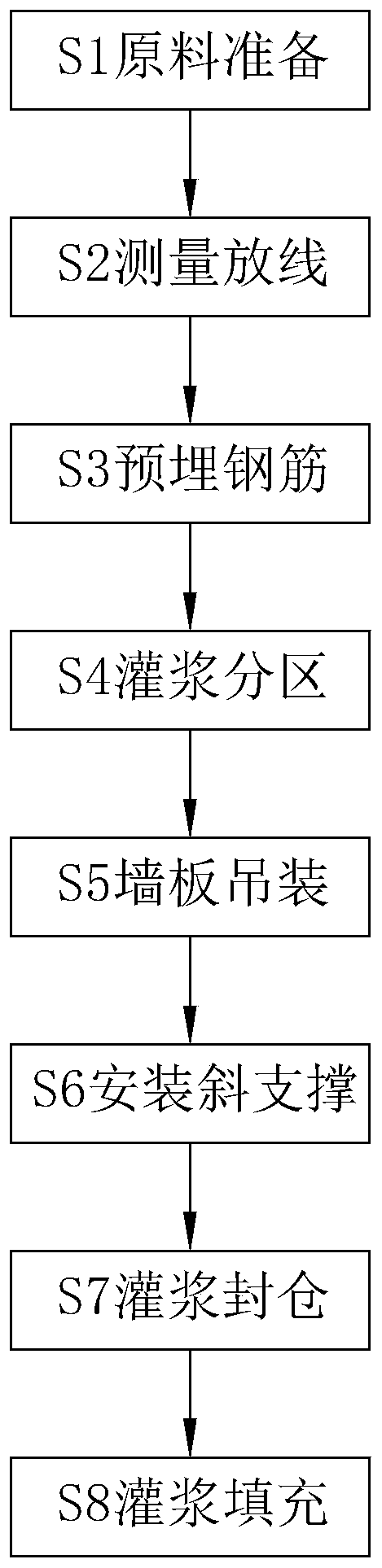

[0047] A construction method for prefabricated wall panels, such as figure 1 shown, including the following steps:

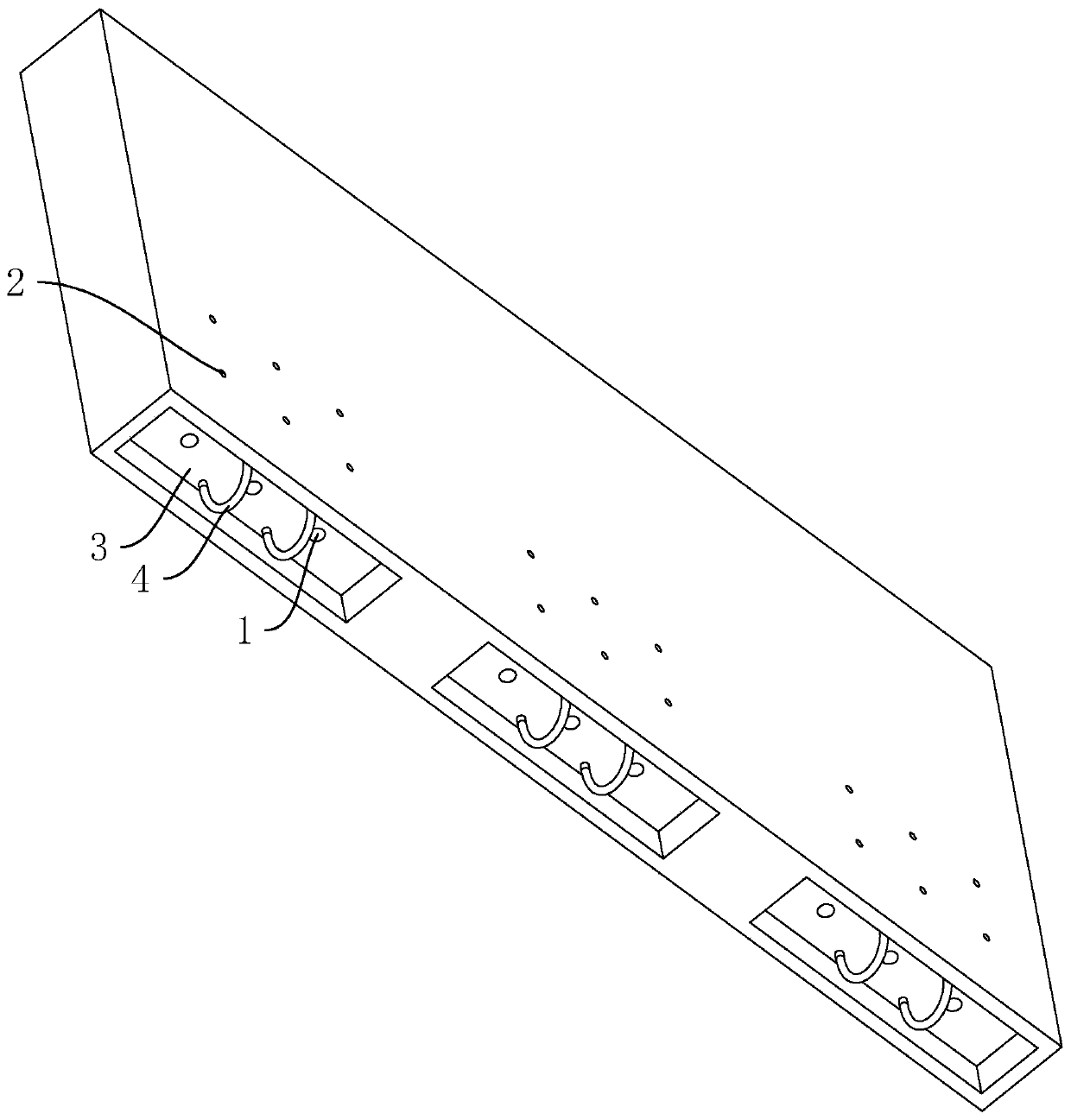

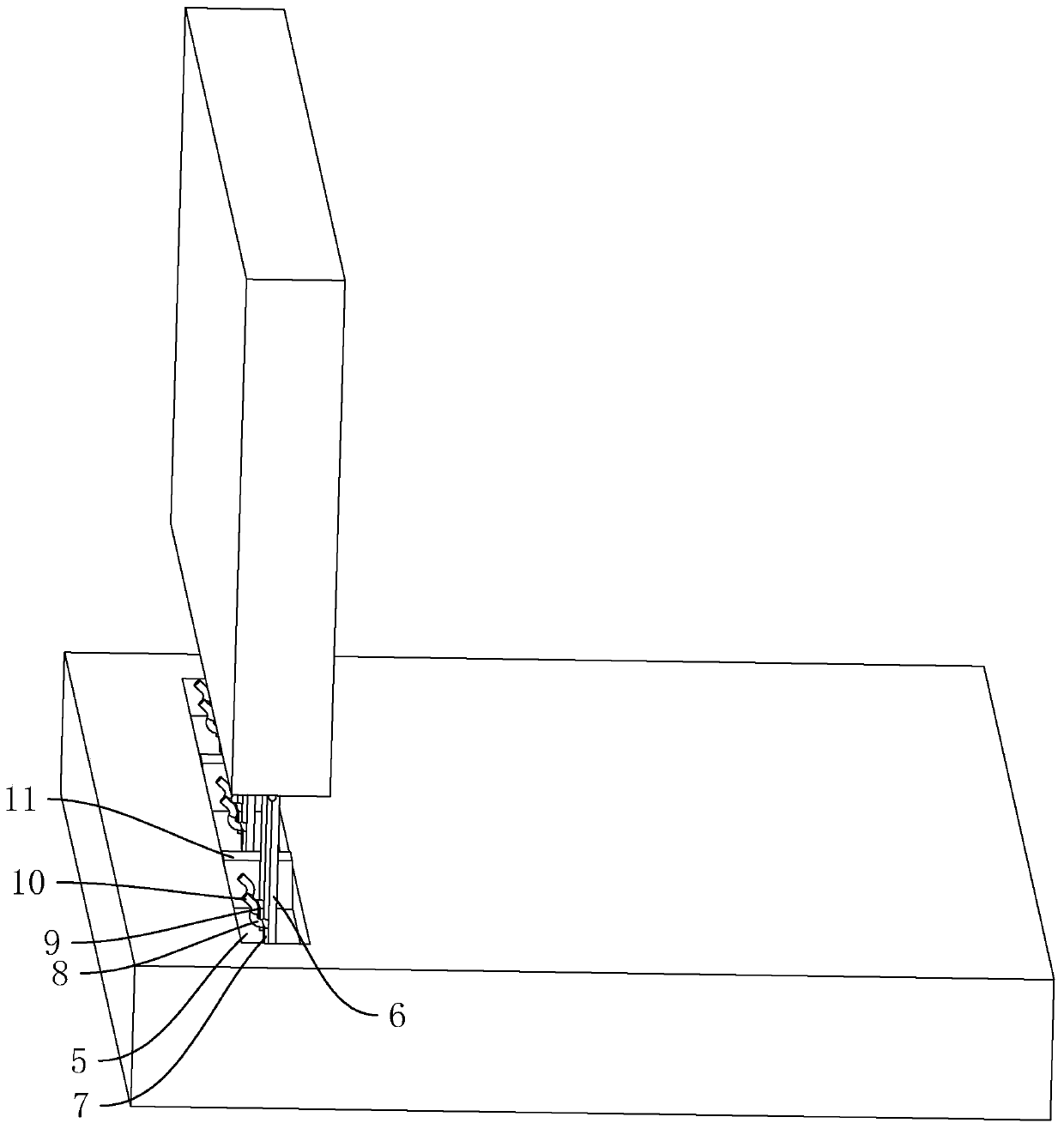

[0048] S1, raw material preparation, such as figure 2 As shown, the lower end surface of the prefabricated wallboard used is provided with a number of notches 1, and one of the end surfaces of the prefabricated wallboard is provided with a number of slurry holes 2 connected with the notches 1, and the slurry holes 2 of each notch 1 are along the vertical direction. There are two connected. The lower end surface of the prefabricated wallboard is also provided with grooves 3 at intervals along the horizontal direction, and the grooves 3 communicate with the notches 1 . A plurality of tie bars 4 are correspondingly arranged in the groove 3, and the shapes of the tie bars 4 are all U-shaped. The diameter of the tie bars 4 is 8mm, and the lower end surfaces of several tie bars 4 are arranged flush and protrude from the lower end surface of the prefabricated wallb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com