A flipping and gripping mechanism installed on a manipulator

A technology of manipulator and flipping motor, which is applied to manipulators, program-controlled manipulators, collets, etc., can solve the problems of complex structure of manipulator collets, and achieve the effect of compact structure, small volume and strong stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

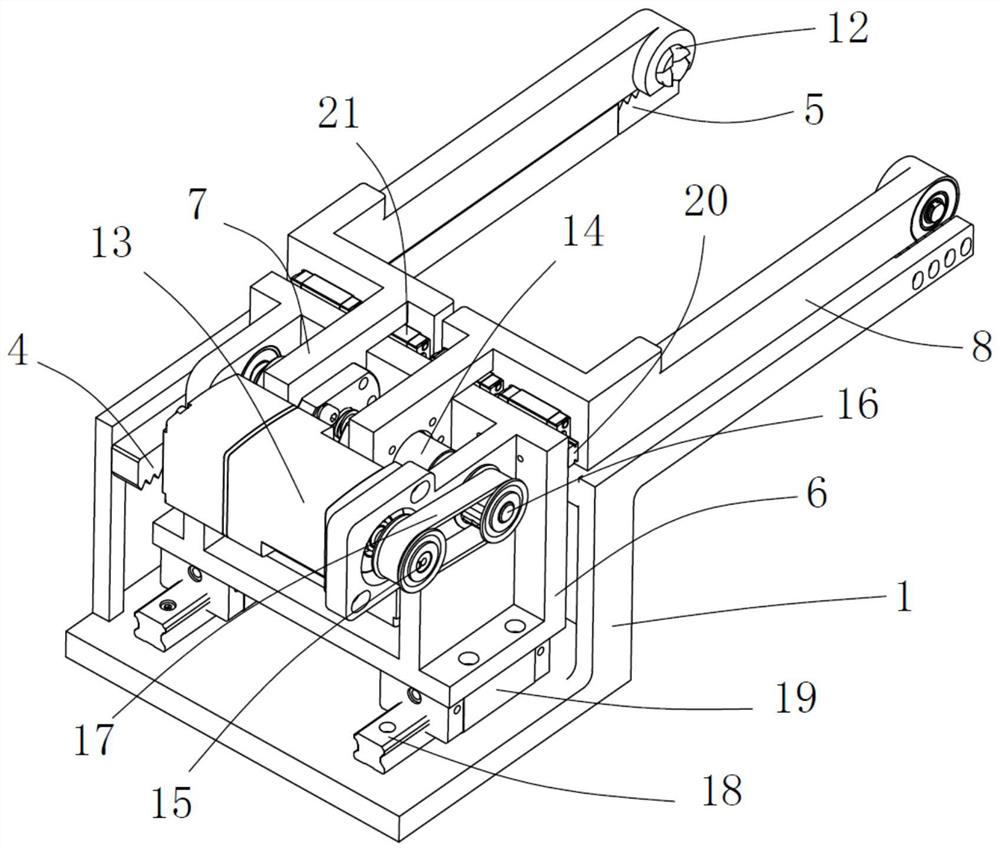

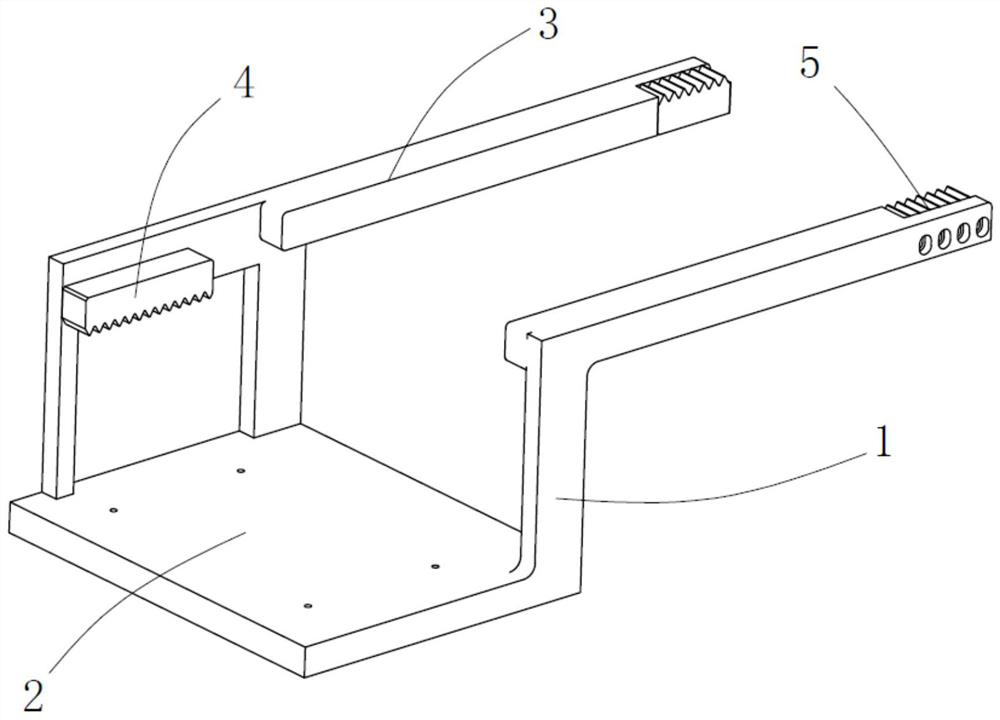

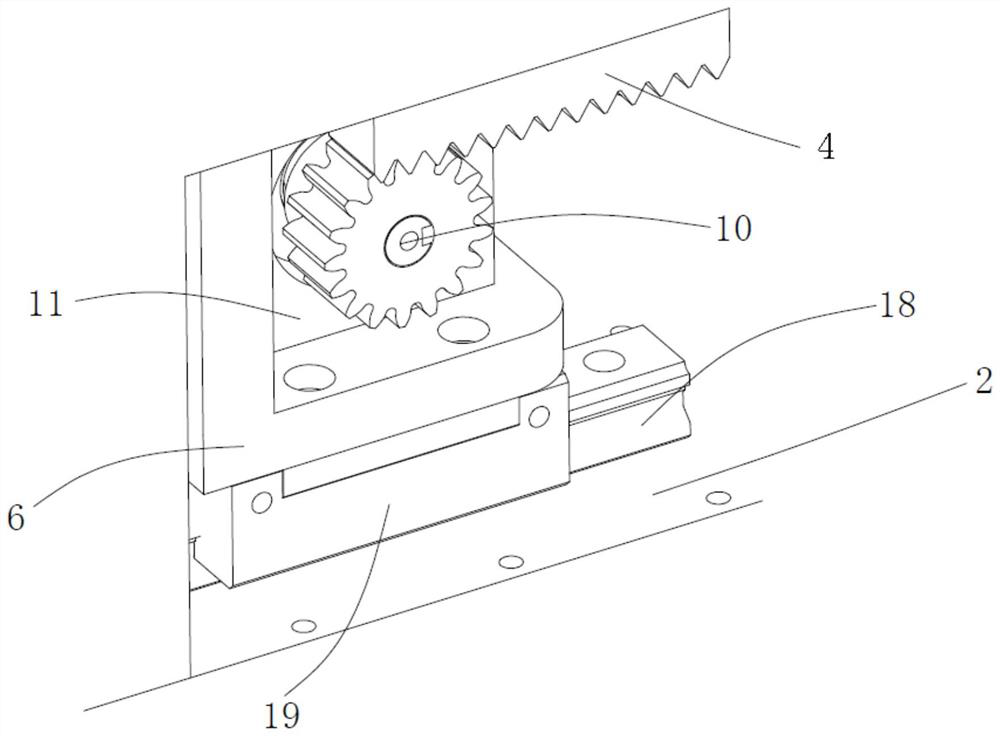

[0024] Example: such as Figure 1 to Figure 5 As shown, a flipping and gripping mechanism installed on a manipulator includes a mounting base 1, and the mounting base 1 includes a support seat 2 and a flipping claw seat 3. The supporting seat 2 is provided with a sliding rack 4, and the flipping claw seat 3 is provided There is a turning rack 5, and a working block 6 is slidably connected to the support seat 2. Two connecting blocks 7 and jaws 8 are arranged on the working block 6. The jaws 8 are fixedly connected to the connecting block 7, and the connecting block 7 is connected to the working block 6. Slidingly connected, the jaw 8 is provided with a turning gear 9 meshing with the turning rack 5, the working block 6 is fixed with a turning motor 11 and a clamping mechanism, and the turning motor 11 is provided with a gear for meshing with the sliding rack 4. The sliding gear 10 and the turning gear 9 are also provided with a turning block 12 for fixing the product to be cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com