Novel low-resistance injection syringe

A low-resistance syringe, a new type of technology, applied in the field of syringes, can solve the problems of large syringes and resistance, and achieve the effects of convenient injection, scientific and reasonable structure, and reduced damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

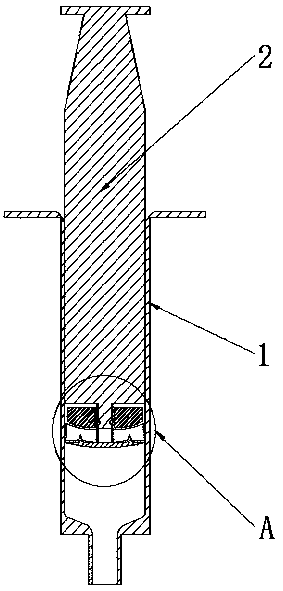

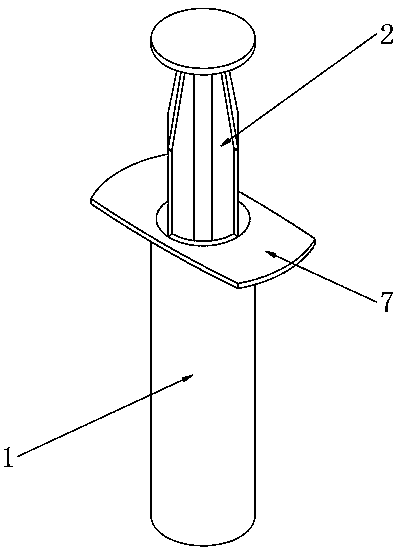

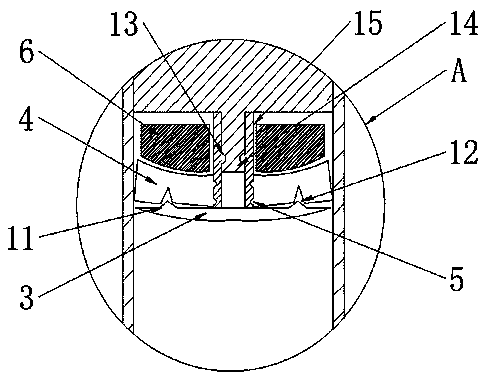

[0031] Embodiment 1: as Figure 1-4 As shown, the present invention provides a technical solution, a new type of low-resistance syringe, including a sleeve 1, a push rod 2 slidingly connected inside the sleeve 1, and a push plate connected to the top surface of the sleeve 1 and the top surface of the push rod 2 7. It is convenient for the staff to push the push rod 2; the tail end of the sleeve 1 is raised to prevent the push rod 2 from reaching the tail end and detaching from the sleeve 1. The bottom end of the push rod 2 is equipped with a piston cap 3, and the shape of the top of the longitudinal section of the piston cap 3 is Conical shape, smooth inner wall of the sleeve 1, meeting the low resistance requirement of the product, with a raised tail end to prevent the push rod 2 from reaching the tail end and detaching from the sleeve 1, so as to facilitate cooperation with the bottom of the sleeve 1 and avoid drug residues in the sleeve 1.

[0032] The inside of the top of ...

Embodiment 2

[0037] Embodiment 2: as figure 1 , 2 , 6 and 7, the present invention provides a technical solution, a novel low-resistance syringe, comprising a sleeve 1, and the top surface of the sleeve 1 is fused with a push plate 7;

[0038] The limit assembly 9 is installed at the bottom of the push plate 7, and the limit assembly 9 includes a fixed block 901, a chute 902, a slider 903, a first spring 904, a limit plate 905 and a rubber plate 906;

[0039] Both ends of the bottom surface of the push plate 7 are connected with a fixed block 901 by casting, and both ends of the middle part of the push plate 7 are provided with a chute 902, the inside of the chute 902 is slidably connected with a slider 903, and one end of the slider 903 is fused and connected with a first spring 904. One end of the first spring 904 is connected to one end of the chute 902 by melting and casting, and the bottom end of the slider 903 is connected to the limiting plate 905 by melting and casting. There is ...

Embodiment 3

[0041] Embodiment 3: as figure 1 and 5 As shown, the present invention provides a technical solution, a novel low-resistance syringe, including a sleeve 1;

[0042] The sleeve 1 is equipped with a protection assembly 10, and the protection assembly 10 includes a fixing cylinder 1001, an installation groove 1002, a second spring 1003, a protection cylinder 1004 and a rubber ring 1005;

[0043] The outside of the bottom end of the sleeve 1 is connected with a fixed cylinder 1001 by casting, and the middle part of the bottom surface of the fixed cylinder 1001 is provided with an installation groove 1002, and both ends of the inner bottom surface of the installation groove 1002 are connected with a second spring 1003 by fusion casting, and the two second springs 1003 are connected by melting and casting. The top surface of the protection cylinder 1004 and the bottom surface of the protection cylinder 1004 are melted and connected with a rubber ring 1005 .

[0044]After the injec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com