High-temperature-resistant spark plug for lean gas

A technology for spark plugs and high temperature resistance, which is applied in the direction of spark plugs, electrical components, circuits, etc. It can solve the problems of increased damage rate, inability to effectively help exhaust gas discharge, spark plugs cannot be stably ignited, etc., and achieve the effect of preventing accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

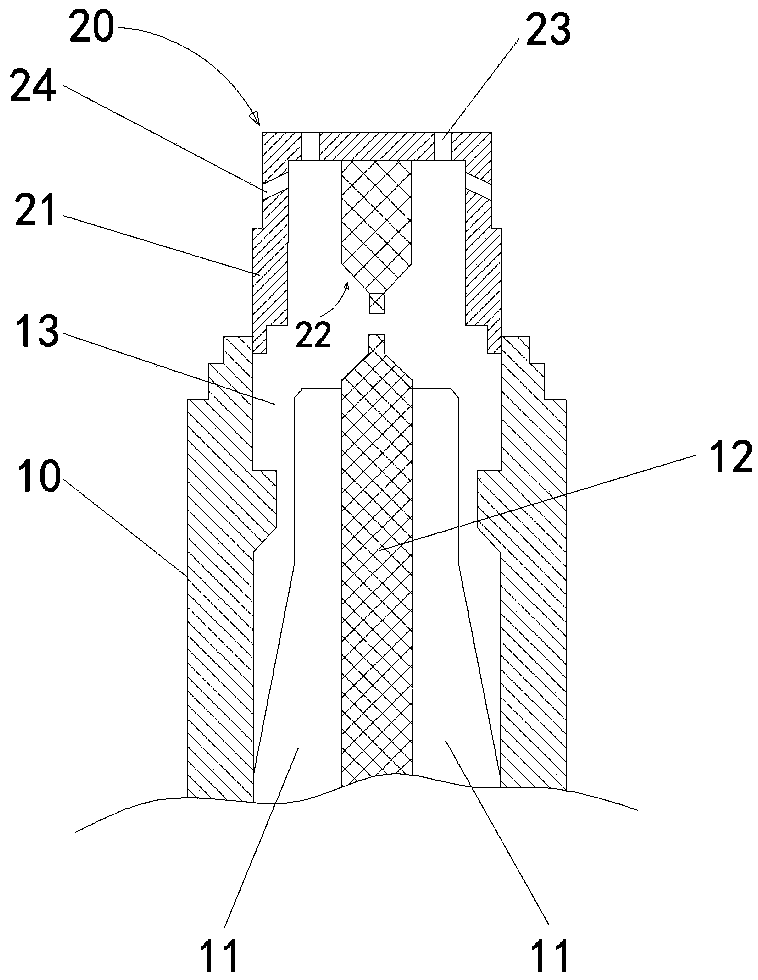

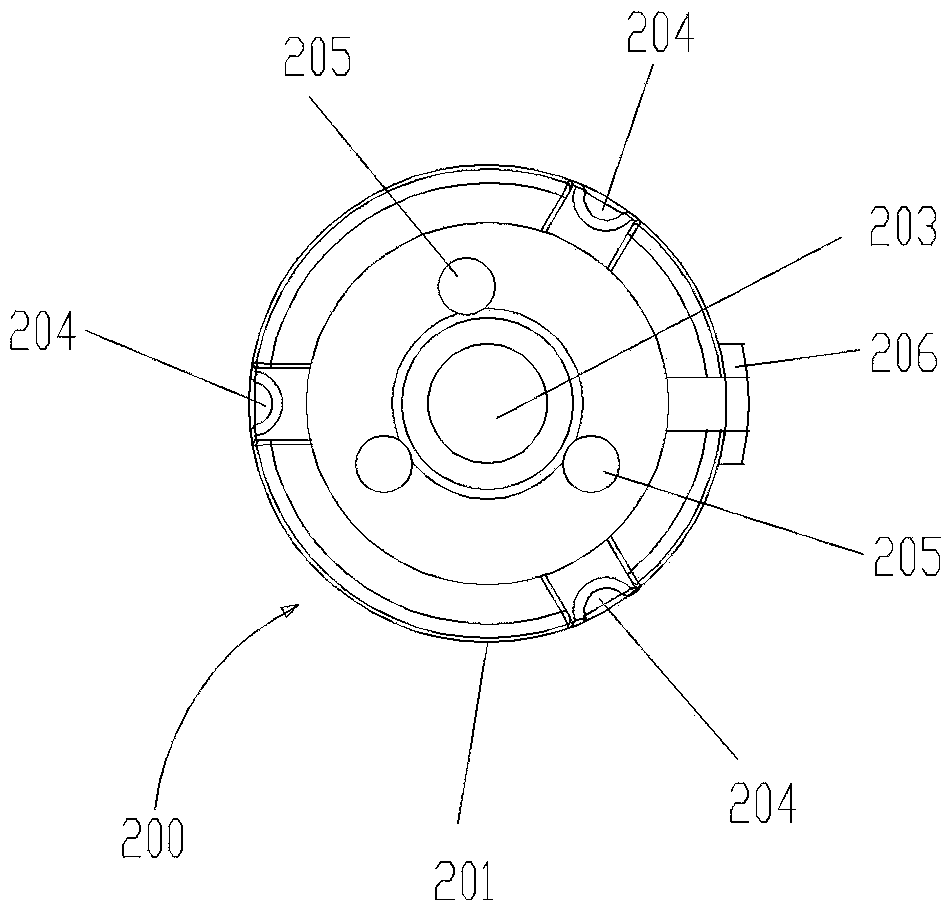

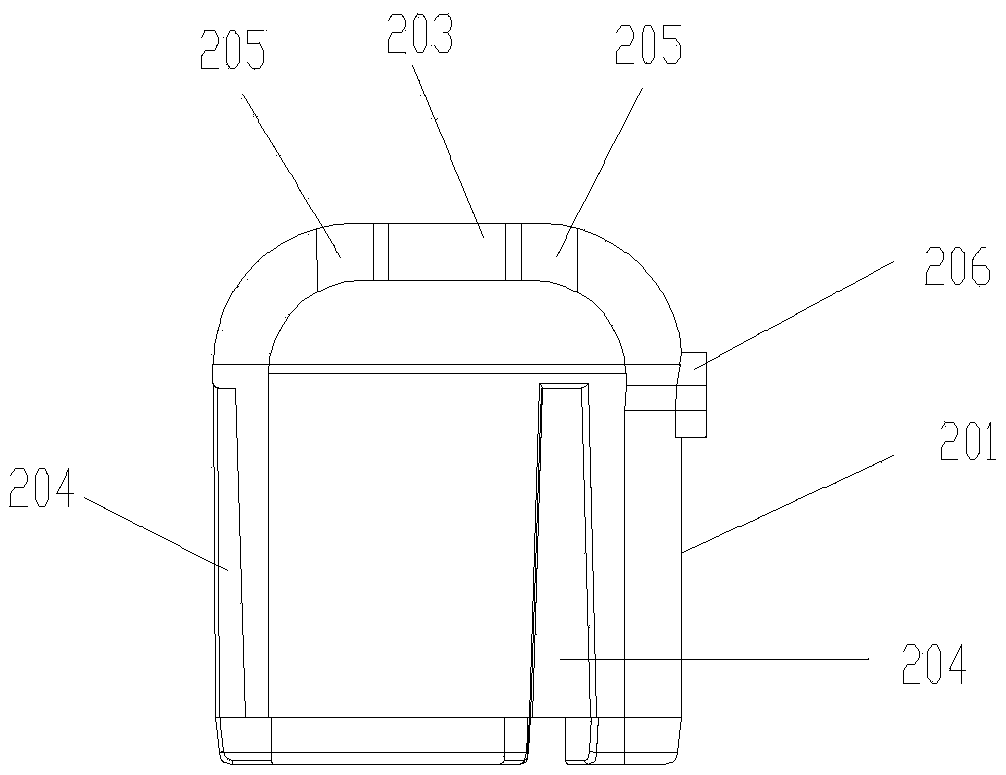

[0026] see figure 2 As shown, a high-temperature resistant spark plug 100 for rare gas includes a spark plug shell 101, an insulator 102 and a central electrode 103; , the central electrode 103 is covered in the insulator 102, the top of the central electrode 103 extends through the insulator 102 and is exposed in the hollow cavity 104 of the spark plug shell 101; a negative ignition unit 200 is arranged above the central electrode 103, The negative ignition unit 200 includes a housing 201 and a negative electrode 202; the lower end of the housing 201 is embedded into the spark plug housing 101 and fixed, and the cavity in the housing 201 and the hollow cavity 104 in the spark plug housing form an expansion chamber; A central air vent 203 is provided at the center of the bottom surface of the housing 201 of the negative ignition unit 200, and a longitudinal arc-shaped groove 204 is provided on the outer wall of the housing 201, and the arc-shaped groove 204 extends from the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com