Concrete stirring device used for buildings and having automatic cleaning function

A technology for automatic cleaning and mixing devices, which is applied in cement mixing devices, clay preparation devices, chemical instruments and methods, etc. It can solve problems such as unfavorable work, poor concrete quality, and a lot of dirt in the mixing tank, so as to prolong the service life of the machine and buffer The effect of supporting pressure and ensuring work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

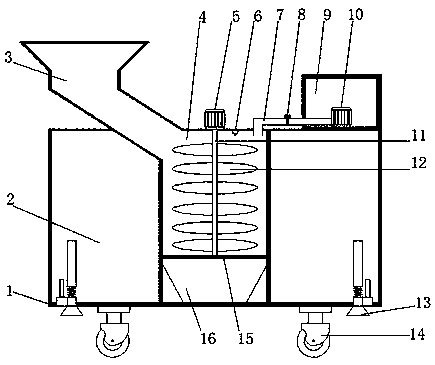

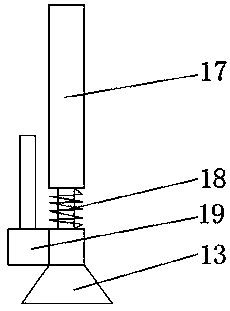

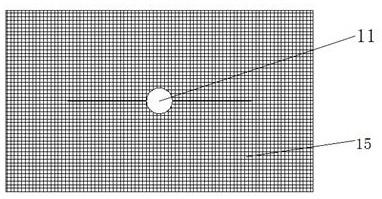

[0021] refer to Figure 1-3 , a concrete mixing device with automatic cleaning function for construction, including a base 1, a box 2 is welded to the upper end of the base 1, and a mixing box 4 is welded to the middle of the box 2, and an inlet is installed on the left upper end of the mixing box 4. The material opening 3, the top outer wall of the stirring box 4 is fixed with a motor 5 by bolts, and the top of the stirring box 4 is provided with a first through hole just below the output shaft of the motor 5, and the bottom end of the output shaft of the motor 5 is fixed with a rotating shaft by bolts 11, and the rotating shaft 11 passes through the first through h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com